Leaderboard

Popular Content

Showing content with the highest reputation since 08/26/2011 in all areas

-

Version 1.0

104,757 downloads

This is the same manual that is already available here on VFRD. I have been using this so much lately that I went ahead and made it a little more useful for myself. I assumed that some other members might like to have it as well. Combined both files into one. Optimized the file size so that it is only 60 MB. Ran OCR text recognition to enable text searches on the entire book. Rotated pages that had landscape page diagram for ease of viewing. Created bookmarks for each chapter & sub-chapters. I figured this was the least I could do to contribute since I am getting so much help from this forum.25 points -

21 points

-

20 points

-

From the album: Michigan to Colorado 2012

At Independence Pass, CO on the way to Aspen during a day ride while at the MSTA's 2012 STAR event in Avon, CO. From MI, we took a northern route from via 95% secondary roads. Saw "real" America and met unique Americans.© ©2012 AnnieR

20 points -

From the album: my VFRs

This totem is the Salish Bear pole at the summit of the Malahat highway near Victoria BC. It was carved in celebration of the 1966 centennary of the merger of colonies of Vancouver Island and British Columbia. The elevation is a modest 356 metres, or 1157 feet, above Saanich Inlet which can just be spied in the background.© Lorne Black

20 points -

From the album: my trips

In 1998 I jumped back to the VFR fold with this brand new VFR800. Resprayed wheels improve visual and a Yoshimura RS3 helps unleash the aural. Unfortunately this bike met an untimely end when it was stolen less than a year, and 25K km later.© Lorne Black

19 points -

It is finally time to reveal my project, show the process, and hopefully give back to this great community I have learned so much from! I have been riding on the street since I was 16 (I'm now 30) and have owned a few different bikes: 92 ex500, 97 CBR 600 F3, 2000 DRZ400, 1997 GSXR 750, 2002 VFR 800 and now a 95 VFR 750. Please bear with me as I give a little explanation of how this project came to be... there will be lots of pictures to come! Over my time riding I have always liked the idea of owning a naked style bike like a triumph speed triple. Smooth windscreen-less air, fun sit up riding position, a tourqey engine, fairly comfortable, great on a tight backroad, cool looks... etc. And now that I live in a place with a lot of great backroads I decided it was a good time to pursue that idea. I really liked my VFR 800, it was smooth, refined and great for trips with my dad. However the idea of tearing it down for a streetfighter project didn't really make sense... too much complication and lots of things to hide. I thought about buying a naked bike but riding a brand new triumph speed triple showed me dreaming about a bike doesn't mean I'm going to love riding it. Besides... I was really on a tight budget with my wife finishing nursing school. So I sold the VFR 800 to a friend and decided to look for a bike to convert to a naked/streetfighter. I had enough money to buy a CBR1000RR or other similar bikes... but I wasn't sure I wanted that much power at my disposal and really loved the refinement and character the V4 VFR's provide. Really nothing I've ridden compares... The speed triple had character but lacked some of the refinement of the VFR. To me it was a no-brainer picking a 4th gen VFR. They have a good looking frame, a radiator in front, and are less complicated than 5th and 6th gen bikes. So I found a 95 VFR with 34000km in quite good condition to start the transformation. I know many of you will not like that I tore into a VFR in quite good shape, but let me give you a bit of my reasoning. Anyone who has tackled a project bike will probably attest to the fact that starting with a good base will avoid a lot of extra head-aches down the road diagnosing issues, wondering about frame straightness, fixing and repairing all sorts of components along the way... etc. And a bike in good shape allowed me to sell parts along the way to raise money for the build. Besides, I know the look of the VFR is a huge part of it's identity, but really that's just a plastic shell and in the end and the V4 engine is the heart of the machine. Anyway, my goal here was to have a bike that road like brand new in the end. To have a bike that I wish honda would build (though I probably wouldn't be able to afford it anyway...). OEM+ was the idea. I would give a lot of thought along the way to making a bike that functioned, looked and rode for the most part like an OEM product or better. I rode this bike for a few months until my regulator/rectifier went up in smoke... suprise! Oh well... winter was around the corner so it was a good time to start tearing it down! Along the way I had to source A LOT of parts and components (I'll make a bit of a list at the end). A big one at this point was the CBR929/954 front end swap. The forks and brakes were actually purchased from Bailyrock! And let me tell you... I think these forks are brand new :) I did some photoshop work and decided I wanted to try and adapt a speed triple seat. It looked like it would fit around the tank and it would allow my wife to ride on the back. Then I set about mocking up the subframe in wood. Then I recovered the speed triple seat with a luimoto cover Got my wheels powder coated Bought a Two brothers muffler used for a speed triple and had the V.A.L.E flange welded to a delkevic mid-pipe for the 4th gen bikes Put the wheels on so I could keep building After I was happy with the subframe mockup (test fitting the placement of the passenger pegs for my wife was kind of interesting with a wood frame...) I set about using my carpentry tools to cut up some aluminum. My dad gave me the tip of making a jig for the welder to hopefully keep his labor costs down... While the subframe was away for welding I cut off my front fairing subframe mounting tabs, fitted my front headlight (with mounts machined by a custom fighters.com member), and made a 929 shock adapter. It's starting to come together! The subframe back from the welder! I'm very pleased with the result... My ballistic battery and koso gauge came in. Made a gauge mount for the RC51 triple and let the bike out for a little air Now it was on to bodywork making time... This was a HUGE part of the project and I learned a lot along the way. I used 1" LDF glued together to shape the plugs for the parts. I'll let the pictures do the talking... And here are the plugs ready for fiberglass... a lot of things didn't go as planned at this stage and my moulds needed a lot of work to make even rough parts. But in the end I was able to come up with one off fiberglass bodywork. I knew this would be a lot of work... but it ended up being even more. And then I still had to figure out all the mounting tabs... I thought it would never end. Eventually I was finally ready to tear the bike down for thorough cleaning and powder coating. I had everything done in a fine texture black and the exhaust ceramic coated in a kind of matte aluminum color. It was like christmas unwrapping all the parts :) Then it was reassembly time. My dad came and helped me out for a few days. It was great to have his help and skill for this part of the process. I love that we have a common interest in bikes! Had a good weekend and got the bike into a rolling chassis. I'm sure my Dad has had enough of repacking bearings for a while... Then it was back to figuring out how to mount the bodywork and getting the parts ready for paint Found a nice spot to mount my ignition and made some aluminum bezels The CBR1000 front fender has some broken mounting tabs Made a battery/electronics box out of aluminum and covered it in 3m CF vinyl Found a local painter who let me help with the prep work to keep costs lower (he would spray the high build primer and I would do the wet sanding/spot filling) After a few rounds of primer and sanding the parts were all ready for paint. The plan all along was to match the stock pearl red on my tank and the painter didn't think this would be a problem with his ppg system... until he actually tried to enter the info into his computer. Apparently ppg doesn't have this color in their system. So... because the tank was getting painted anyway, I could choose whatever color I wanted! I knew red would look good... but I wanted something unique and fun, without being ridiculous. So I chose something else completely... While I was waiting on paint, I tacked the electrics, fuel pump and wiring harness... which is a TON of work and something I would like to do a better job of eventually. All the connections are soldiered and heat shrinked, and I used good connectors where needed, but to really do a good job of routing the wiring and taking out excess will take more time. And then the parts came back from paint! Its called Azzuro Meditterano (or something like that) and it's a ducati monster color. I know not everyone will like it, but I love blue and am very happy with the color! PS the seat cowl is a Carbon Fiber speed triple part I got off ebay. I haven't started making carbon fiber parts yet... maybe someday. I did however modify the sides of the seat cowl with fiberglass to help it blend in with the tail section better. And now its time to reassemble the bike completely! My dad rode his brand new Multistrada 1200 over from alberta to help out. Final assembly was a lot of work and I would prob still be working on it if it wasn't for my dad coming to help. Anyone who modifies motorcycles knows that every change affects so many other things... needless to say there were many things to figure out, and some that will be a work in progress. It took me over 9 months, and there are still some things to complete or change, but here is the mostly final product!!!! So far I have put about 1300km on the bike and am loving it!!! It has turned out to be pretty much everything I wanted it to be. I will give a more detailed ride report later but for now I need to take a break from the computer :) I hope everyone enjoys seeing the process. There are so many details I didn't cover but I will list the mods later and answer any questions people have as best I can. I need to thank this forum a million time for all for all of the things I learned from those who have done these kinds of mods before. You are a great bunch and I appreciate all of the help. Also my Dad deserves a huge high five for all of his help, My Uncle for all of the last minute tech support and above all a gigantic thank you to my wonderful wife for putting up with me as I built my dream bike!18 points

-

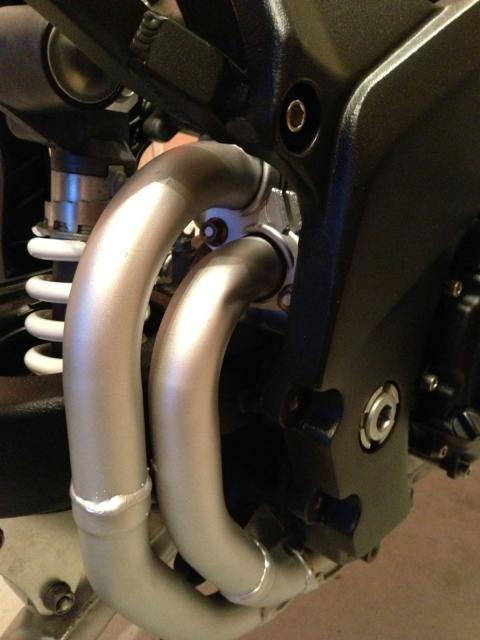

Well, my idea of one, anyway. aka, I collected parts for 10 years and finally installed them all... (a year ago, sorry ) aka, my bike needed a refresh after almost 50kmi and sitting unused for the last 5 years. I started this work early December 2021 and finished just shy of 6 months later in May of 2022, so this story has been a long time coming. I bought this 2005 VFR800 brand new 17 years ago in February 2006, and I started with some light modifications right off the bat. Mostly good practical ones like a throttle lock, comfy seat, mirror extenders, suspension work, luggage, etc. Being a member here prior to purchase and of course ever since, you get a lot of ideas and sometimes even some good deals on gently used parts and unique parts made by other talented members. Over the next series of posts in this thread I'm going to highlight the bucket list of parts I collected & fabricated, plus the modifications I made to my bike to make it into my dream VFR. Here's a pretty comprehensive list of what the build is comprised of: - 2005 VFR800. Bought new, now 48,xxx + mi - Powdercoated frame and subframe satin black - Wheels powdercoated "Wet Charcoal", added angled stems - 2005 Yamaha R1 forks upgraded with: ~Racetech 1.0kg springs ~Racetech G2R comp valves ~Traxxion rebound valves ~cartridges tuned by Traxxion ~Maxima 7wt 125-150 oil @115mm air gap - R1 front fender painted R258 Winning Red - Sebspeed triple clamp set, 35mm offset, integrated bar risers & custom riser bridge - Handlebar conversion to Superbike bar - Brembo 16RCS clutch master - Oberon billet clutch slave - Brembo 19RCS brake master - Tapered head bearings - Carrozzeria front wheel, 6lb - Custom billet rotor adapters - EBC Vee rotors, blue carriers - Titanium rotor bolts - 08 CBR1000RR Tokico monoblock calipers, Cerakoted "Stainless" with black lettering and rebuilt with oem seals - EBC HH pads - Titanium caliper bolts - Mirror extenders - 06 oem windscreen (?) - Dash lcd update film/led converion - Heated grips - NEP throttle lock - Oem CBR900RR grips - Sebspeed windowed clutch cover - Factory Pro shift kit - Throttle body hoses replaced with silicone - Fuel injectors cleaned and matched - A&A Torocharger kit, modified with: ~ added sc oil cooler and custom reservoir ~ modified cooling system to delete right side radiator, added 2014 VFR800 lower radiator with fan - Boost gauge - Knock sensor - Rapid Bike Race fuel & ignition management - VFRD Two Brothers replica big tube stainless header, RC30/8th gen VFR style to accomodate lower radiator - Remus carbon fiber slip on pipe set - Sargent seat - Oem luggage, full three bag set, side racks powdercoated - Ohlins shock with: ~1300lb Eibach spring ~Traxxion 1" spacer ~tuned on Traxxion dyno - Ducati 1098 rear wheel swap with: ~Sebspeed adapter kit ~1098 hub/drive parts and brake ~Braking Wave Fix rear rotor ~titanium rotor bolts ~JT quick change carrier ~titanium sprocket nuts ~Marchesini forged 1098 wheel, 9lb ~Superlite sprocket ~DID 520 chain ~geared -1, +1 (15/44) - Roadstercycle SH847 Super kit - Oem stator replaced with new - New battery - Core Moto custom brake & clutch lines17 points

-

...I bought this lightly used 2 year old VFR750, and haven't been without a Honda since then; several VFRs and a handful of VTR1000F. I'd bought the bike late that afternoon, and being early March it was a dark, damp first ride to visit my folks. I'd love to have it back, and in that condition.15 points

-

I took advantage of some sunshine the other day to do some pre-season checks. I addressed a fuel stumbling/ground issue and looked everything over since I had literally this entire bike apart last year. I added a heavier ground cable back to the frame from the front subharness, updated the Rapid Bike tuner firmware, reset the fuel and ignition maps 1 & 2 and turned off the autotune. Tightened up 4 of the 8 header studs. Tightened and added loctite to the horn mount. Cleaned and adjusted the chain. Checked fluid levels. Wiped down the forks. Going to save a bath for nicer weather. Put about 30 miles on and temps hovered around 170°f on this 41° day. Pretty fricken stoked at how this bike turned out after the massive work I put into it.15 points

-

This guide was created because I couldn't seem to find one that was very thorough and included pictures of all procedures. This guide requires the use of Speed Bleeders as it makes life so much easier! You can follow this guide using the old school method as well, but it will require more time and patience. Readers Notes: Left and ride side are determined as if you were sitting on the motorcycle. Images come after descriptions. Initialisms: LBS: Linked Braking System LPCV: Left-side (Servo) Proportional Control Valve (Battery side) RPCV: Right-side (Rear) Proportional Control valve (Opposite battery side) LMC: Lever Master Cylinder (Front) RMC: Rear Master Cylinder (Pedal) SMC: Secondary Master Cylinder (Left-Front Caliper) FSM: Factory Service Manual Parts Required: One man bleeder kit (optional) ATE SuperBlue Dot 4 Speed Bleeders Part Numbers: Front right caliper SB8125 Front left caliper outer bleeder SB8125 Front left caliper inner/centre bleeder SB8125 Rear caliper outer bleeder SB8125 Rear caliper inner/centre bleeder SB8125L Clutch bleeder SB8125L LPCV SB8125LL RPCV SB8125 Part 1: Theory Part 2: Diassembly And Prep Part 3: Procedure Part 4: Assembly Part 5: Clutch Part 1: Theory The LBS is confusing for some when it comes to understanding how it works. The function of the sytem changed from 5th generation LBS to 6th generation LBS. I'm not too sure what the changes were, but I do know they operate differently. The way the 6th generation LBS works is; when the front lever is applied, only five out of the six (three pistons in each left/right caliper) caliper pistons actuate as well as the centre piston in the rear caliper leaving the left caliper centre piston untouched. When the rear pedal lever is applied; only two out of the three rear caliper pistons actuate as well as the left front caliper centre piston. The LBS only works when the motorcycle is moving however, you can test this by propping your bike on the centre stand, rotating the rear wheel and applying the front brake; the rear wheel will not stop spinning. The way it works is by force. The SMC is mounted above the left caliper that's attached to the fork and with the motorcycle moving, the rider will apply the front brake which squeezes the pads on the rotor and that drag pivots the left front caliper up which actuates the SMC and brake fluid gets pushed through to the LPCV and then to the rear caliper centre piston. The rear doesn't work in the same way because there's actually a brake line that goes all the way to the front left caliper that actuates that one centre piston by it's lonesome with the application of the rear pedal. Thanks to BartmanEH for the above picture! Part 2: Disassembly And Preparation You want your bike to be on a level ground and prop the bike up on it's centre stand for this whole procedure. Rotate the handle bar all the way to the left so the LMC is level. Remove both screws and remove all the old fluid inside the LMC. You can use a turkey baster or rags, whatever you wish. Once the old fluid is out, fill it up with fresh new fluid. Make sure you squeeze the front lever a few times just incase you got any air bubbles when removing the old fluid. Using an allen wrench, loosen, but do not remove the left front caliper bolts. Remove the seat and do the same procedure you did for the LMC to the RMC. Don't forget to press the pedal lever a few times to remove any air bubbles. Remove the rear wheel. Remove the two bolts that hold the rear caliper together. The inside one is tricky and I needed to use a long 12mm socket to reach it. Once the rear caliper is removed, mount it at the 10 o'clock position on the rotor. The reason for this is so the inner/centre bleed screw is facing up, not parallel to the ground. Part 3: Procedure The procedure and order we're going to follow is the same one listed in the FSM, but with more pictures and explanations. Sections C. and D. are the most difficult. You will need a helper as well. USING FRONT MASTER CYLINDER LEVER FOR A. AND B. A. Left Front Caliper, Upper/Outer Bleed Screw This is basic bleed. Open very slightly, usually about a 1/4 turn and pump the front lever until new fluid comes out. Even though I use speed bleeders, I still pressurize it old school method just to be on the safe side. The old school method is; with the bleeder screw closed, have your helper pump the front lever five times and hold. While holding, gently unscrew the bleeder screw until fluid comes out and before the lever reaches it's maximum travel, tighten the bleed screw. Top up the fluid level. B. Right Front Caliper, Single Bleed Screw This procedure is the same as above. Make sure you keep an eye on the fluid level as it drains. USING REAR MASTER CYLINDER PEDAL FOR C. TO G. C. Leftside PCV (Battery side), Single Bleed Screw Actuated via SMC This step is the most confusing and difficult one as it requires good timing between yourself and your helper. The SMC is not attached at all to the front lever in anyway. You can unscrew the LPCV bleeder screw and pump the front lever all day long and no fluid will get pushed through. You could manually actuate the SMC by hand and only a little bit of fluid will come out and then stop. The correct method to do this; from what I've gathered on how the system operates and without using a vacuum bleed tool is as follows. Remove the two bolts that hold the left front caliper on. I used an aluminum L-bracket I had lying around to wedge between the pads so they don't close. Tilt the caliper 15° from the ground so the inner/centre bleed screw is facing up. Your helper will be on the RMC side pressing the pedal and you will be at the left front caliper in charge of manually actuating the SMC and loosening/tighten the LPCV bleed screw. The way this system works is; there's a brake line that goes from the RMC to the SMC and from the SMC to the LPCV. Because there's no reservoir at the SMC, there's no way for new fluid to replenish to continue being pushed through the lines and out the LPCV bleeder screw, however, this is where the RMC comes in. When your helper presses the RMC pedal down, the SMC piston will get pushed out filling it with fresh fluid. Once your helper releases the pedal, you will manually actuate the SMC by pressing it in to the caliper with your hand and fluid will get pushed through to the LPCV bleeder screw. Push the SMC in with your hand. Do not release from this point. Tell your helper to press the pedal again which will forcefully push the SMC out and then once your helper releases the pedal, you will manually push the SMC in again watching for new fluid. Once fresh fluid is coming out, I performed a final pressure bleed by tightening the LPCV bleeder, asking my helper to pump the rear pedal five times and release, then I loosened the LPCV bleeder screw and manually actuated the SMC gently half way and then tightened the bleed screw. Note: Even with speed bleeders installed, I did not manually operate the SMC more than once for safe measure. To further elaborate on this; continuously pushing in the SMC numerous times will not bleed the SMC to LPCV brake line because there is no reservoir at the SMC. You will push whatever fluid is in the line and it will become empty with air. One manual push of the SMC followed by one rear pedal actuation by your helper. D. Rear Caliper, Inner/Centre Bleed Screw Actuated via SMC This procedure is the exact same as the above. The only difference is, you're bypassing the LPCV and going all the way to the rear caliper inner/centre bleed screw. Pressurize the sytem the same way as above too. E. Rightside PCV (Opposite Battery), Single Bleed Screw This is the easiest step. Follow the procedure as in Section A. but using the RMC pedal. F. Rear Caliper, Upper/Outer Bleed Screw Another easy step, follow above procedure. G. Left Front Caliper, Inner/Centre Bleed Screw The last procedure, again very easy, same as above. Part 4: Assembly Top up both fluids if they are low and fasten all caps and lids back on the reservoir. Attach the front left caliper and torque the pivot and joint bolts to 23ft-lbs. The FSM says always use new bolts, but I cleaned up the old loctite residue, re-applied some new medium strength loctite and re-used them. Attach the rear caliper and torque the joint bolts to 23ft-lbs. The FSM says replace also but I did the same as the front caliper bolts. Reinstall the rear wheel and torque bolts to 80ft-lbs. Now would be a good time to prime (pump a few times) your front lever and rear pedal lever. Once primed, they should not travel a lot of distance; they should feel stiff. If for any reason the levers travel a larger than normal distance, then there's probably air in the line somewhere or you might have forgot to tighten a bleed screw. Note: The FSM says to use new bolts, not because there is something wrong with the bolts, but because there is probably some sort of loctite already applied to the threads. Thank you Metallican525 for that insight. Part 5: Clutch I don't have to go in to any detail about this because if you just did your whole brake system, might as well do the clutch as it's very simple and same procedure at Part 3, Section A. Remember to turn the handle bars to the right though. At the end, I took my bike for a ride and I had no idea that this bike has this much braking power! Mind you, my fluid was 6 years old which was probably the cause of that but this method works flawlessly. I hope this DIY was very thorough and gave you a good understanding on how to tackle this easy but tiresome procedure!15 points

-

15 points

-

It's been around 18 months or so since being able to do and fairly easy 385k round trip ride to my favorite winery, mostly on nice quiet back roads. I've had a few hospital visits and major cancer surgery to get through, anyhow, the short story is I'm feeling great now and have another 12 months or so of Immunotherapy to get through then hopefully I'll be in the clear. Today was a bit of a test to see how I'd handle the longer times in the saddle along with a picture perfect Spring day for riding, everything went well, happy me. There's a great winery I enjoy riding to in a tiny country town called Moonambel (Victoria Australia, Google Maps will get you there!!), an old Gold mining town, but the only Gold you'll find there now are the Red's produced by - Summerfield Winery. Here's a few happy snaps of the day Safe Riding All. Cheers On the way up "Fields of Gold"everywhere, Canola in bloom. Not quite Las Vegas. Apart from the Winery, there's the Motel and a General Store, a small town well known for its local wineries. The brilliant wine maker himself Mark Summerfield - Liquid Gold! Time to fill up the Panniers and head for home. The bike just loves Reds! Mark and the winery staff know me as "The Red Baron". The VFR and my wine pickups have featured in one of the Wine Club newsletters. I've made eight wine travel canisters out of 90mm PVC storm water pipe with a solid cap on one end. I roll up each bottle with bubble wrap then slide it into one of the canisters, I can fit up to 4 bottles in each of the pannier internal bags and haven't had a breakage yet. Not the most efficient way of purchasing wine, but it's an enjoyable day on the bike and any excuse to pick up some fine Reds is a good one! Have to admit my 8gen with 93,000k's on the clock, never ceases to put a smile on my dial.14 points

-

If you want I'll continue hosting and maintaining the invision license. I'm in IT and am intimately familiar with what's required. Forums shutting down like this is a huge knowledge drain and will hurt future VFR owners as the bikes age into classics and collectables. It would be a shame for decades of info to be thrust into the darkness instead or kept afloat on a life raft. We can migrate you to a free LetsEncrypt certificate there's no need for a paid one for a non-commercial site. Shoot me a message here or Facebook if you'd be interested. I would make no changes, and just continue to maintain it on a technical and fiscal level. Please, no. Let's stop putting knowledge under their ownership, I've already lost another forum of over a decade to them that they ended up shutting down.14 points

-

From the album: my trips

I spied this interesting rock formation along Cal-247 just north of Joshua Tree, California in 1994.© Lorne Black

14 points -

14 points

-

Hey all, I know some of you had read about my latest "adventure" from the header thread posted by sfdownhill. Just wanted to chime in directly, as it was truly an ADVENTURE! I should first say, thank you to both sfdownhill and shotgunz, these two are some of the best people you can have on your side. Even if they could not contribute to my betterment medically, just their presence and their visits really helped me recover mentally. Knowing I have such good people who care about me really made a difference, so thanks guys, I really appreciate you stopping by! As for my story, well, that started 16 years ago I guess, when I went to the Dr. to see why my upper arms seemed to be going numb every once in a while. Well, after being poked and prodded and quizzed and scanned, we did determine a pinched back muscle was the cause BUT they did find something inside my head via an MRI that really shouldn't have been there. Yep, some little "tumor" like item that was beneath my forehead and just behind the left eye. Well, of course that brings up a whole other topic of what to do about it. The Dr. I had did not think it was something overly threatening and felt that it had been there awhile and based on what he saw in the MRI, felt I was probably something we could keep an eye on. That is, unless I wanted to remove it then. After a few conversations and feeling good about it, we decided to just keep an eye on it, meaning take MRIs of it every 6 months or so, so that's what we did. Fast forward another 15 years and BANG! The tumor decided that it needed a little more room, so it grew a CM and that's all it took to trigger a seizure! Yep, 1AM or so in the middle of December 28th, 2022 my wife wakes up to me "snoring". Well, so she thought. The normal process is to poke me in my side and tell me to roll over on my left side so my snoring stops. Well, that didn't work. Let me shake him awake and see if he'll turn...hmm, that didn't work either. Wait a minute is that snoring? Realizing that what we normally do did not work, she listened more carefully, note that she had lost a lot of her hearing some years back, so somethings don't always sound like what they are. Well, on comes on the bedroom light and low and behold, yours truly was having a full-on seizure. She sees me biting my tongue, blood coming out my mouth and me in full on seizure mode! BAM! runs straight to the phone, calls 911 and low and behold, within minutes the ambulance is there ready to rush me to the hospital. She literally saved my life folks, had she not been there or reacted as fast as she did, I would have most likely drowned on my own fluids. So, if I say or do anything here on the forum that upsets you, you can blame her 😉 What was so weird and odd about this happening, I had no recollection of anything up until I wake up in an ambulance strapped down to the gurney. WTF! As I start to come to, I start looking at where I am and what condition I'm in..."Wait, I'm in my pajamas strapped to a bed, holy s#!t, they've taken me from my bed! Where's my wife, please tell me she's not in this same predicament????!" Well, the crew start to let me know what exactly is going on but I'm still a little slow to process but ultimately demand I be released from the bed, unfortunately, I wasn’t, and I finally get to the hospital. Here is where I finally become more myself again and learn of what had transpired. This is also when they start to really quiz you to see exactly where you are mentally. Gratefully I am answering their questions well and accurately BUT one of the crew decides to quiz me on when I was married. I let him know, "October 17, 1998", he then asks, how long have you been married? I say 20 years or so...He snapped back "It's 24 years!" Oh no you didn't! I raise my head look him in the face and say very vocally "At least I got the F#cking date right!" Oddly, this is where I felt I wanted to smack him! Alas, I didn't. Probably for the better. 🙂 Well, a week later I'm talking to the surgeons and getting ready for my Craniotomy. When did that happen? Friday the 13th! Yes, you heard that right, all good though, everything went well, could not have asked for a better outcome. I have to say that all in all, I been through a lot but can honestly say that I feel really good and have very little to NO PAIN! Can't ask for better than that, right? Unfortunately having this surgery means a few things, #1, No riding of motorcycle for quite some time ☹, #2, No drinking for quite some time, but that's not always a bad thing. #3, get healed up! What can I add here, for sure 2 more things, #1, you can never have too many friends and family to support you while you are in the hospital, whether that's before, during or after surgery. And ultimately...IT'S GOOD TO BE ALIVE! Cheers, D13 points

-

Hello again fellow Vifferini! Some of you may have read my long winded story here of getting back on a VFR after a 15 year absence from riding. I then posted the clean up thread here about that bike. Since purchase I have put about 10,000 miles on it having an absolute blast riding around the fine state of Utah, USA. The warm weather season is short but we do have a handful of excellent roads with endless scenery. The bike is set up just like my first VFR and it runs perfect. I couldn't be happier with it. Well, the plot thickens...which is to say I tracked down and bought back my original VFR. The one that I bought new in Northern California back in 2001. Yes, my actual exact bike, VIN #00089. Turns out the internet can be an interesting and effective tool. I actually got in touch with the owner a couple years ago but he wasn't ready to sell at that time. Finally, in recent weeks he let me know that he had upgraded and would sell it back to me, and at a very reasonable price. I was more than pleased, and my teenage son and I made plans to pick it up two states away in California. Not wanting to drag my small open trailer 1800 miles there and back, I wondered if a motorcycle would fit inside the wife's minivan. The Google machine quickly confirmed that I was not the first to consider this, as I found multiple pictures of various bikes shoehorned into spaces more commonly filled with soccer moms and soccer kids. That said, we had to test before the drive just to be sure. After some general measuring I figured that if we removed the windscreen and mirrors from my current VFR, we might be able to load it through the side door, which is exactly what we did. "Easy does it. Left a bit! Watch the ramp!" Success! Even got the doors to close with room to spare. Took it right back out and put it in the garage, neighbors shaking their heads, unsurprised at my usual shenanigans. So with that confirmed we made our way out to CA to pick up the original machine. Let me say this, one-on-one time with your kids is absolute gold. While going to get my old bike was cool, 20 plus hours in the car with my son was the real highlight of the trip. He's a fantastic kid and we had great time making new memories doing something that wouldn't make sense to most people. We arrived just after dark at the seller's home after a full day's drive. It was great to meet the gentleman and trade a few stories. I pointed out the small scratches on the clutch cover. "Yeah, that was me, trying to put it up on the center stand one day wearing flip flops and it slowly went over on it's side on the driveway. Not my first bonehead move." It was so cool to see that it still had every mod that I had installed more than 20 years prior, save the Sargent seat, but I'll just use the one from my other bike now. Looking over the bike further I noticed that he had the db killer installed on the Staintune, something I never used in my ownership. "Have you heard it without the db killer?" I asked, reaching for my set of Allen keys. "I didn't know you could remove it." he said. A few seconds later I had it out and fired up the bike inside his carport. Let it warm up for a bit and then gave it a few mild revs. "Whoa you can't have it now!!" he said jokingly, "I should have removed that a long time ago!" We both got a laugh. Every VFR guy has their favorite pipe, an uncorked Staintune is mine, though a period Micron is a close second. The Staintune look and sound just can't be matched. I removed the windscreen and mirrors, having done this exercise once before, and we loaded up the bike in the minivan. I strapped it down securely using the factory seat anchors and several ratchet straps. It was almost as if the van was made for this type of thing. We journeyed back home and put the bike in the garage, with some new memories and a new chapter to start. Seeing double, this looks familiar. The more recent left, modded to resemble the original, right. It even has my original plate on the back as plates stay with the vehicle in California. So what now? Get organized, make the punch list. Gotta go over everything to see that it is clean and up to spec. Fluids, charging system, brakes, etc, a nice winter project. The seller provided me with some receipts of maintenance he'd had done recently at a shop near his home. New plugs, valves checked (all in spec), new coolant and brake fluids. Mentioned an issue of stumbling in lower revs that the shop couldn't rectify. Also mentioned a slight coolant leak on the left side and a dent in the left radiator. Interesting but no worries, I have time to look over everything and make it right. When I sold the bike in 2006 it had 26,000 miles on it. Now it shows just 39,000 miles. I can live with that. In general it looks to be in decent shape still, just needing to be gone through a bit. I first removed the side fairings to have a look at things underneath. Hmmm...of the 18 or so fasteners I removed, only 3 were correct and all were finger tight or less. Luckily you can still order the correct ones from Honda. It's clearly been down on the left side at some point. The coolant leak is from an epoxy repair attempt at the bottom of the reservoir. Actually glad to see it's not from the engine casing as the reservoir is easy to replace. Odd repair though. The left rad is indeed dented on the bottom and the bracket bent slightly, though it is not leaking. It will work until I can get another one. When I removed the tail fairing some of the tool kit fell out of the left side, clanging onto the garage floor, and there is a small crack on the left of the tail fairing at the franken bolt insert. Yeah, it's definitely been down. But....(and it's a big but), whomever dropped it did put on an OEM side fairing so that's a win, and everything else I can deal with quite easily. I also took a chance to check voltage and saw 13.70ish at idle and a solid 14.44v at 4,000 rpm, right where it should be as far as I understand. I'll keep an eye on things once I start riding it later. I made a list and ordered a bunch of fasteners and a new coolant reservoir, OEM oil filters and fluids. Just going to take my time and enjoy it. More to come. Cheers, Justin13 points

-

Hi Everyone. My first Post So I'm building a VFR using a lot of different bits and pieces to get in the end my version of a 6X replica. Highlights are Triumph Daytona 675 Wheels. Triumph T595 Forks (45mm) Powder coated Frame, Engine Ported, Vapor blasted and painted. I will start posting photos of the build as it progresses13 points

-

Would be shame to have site go away. I've PMed Miguel and volunteered to keep this site going. Would need some training and help to get up to speed.13 points

-

Hey guys - great news! Darryl (Duc2V4) is recovering well from his surgery. Visited him in the hospital yesterday. He’s walking and talking and mostly his normal flippant happy self. Pain meds are keeping him comfortable and he will be going home today to begin the rehab process. Heading down to the hospital now to see if I can help with the move. He grilled me about whether I’ve been paying close enough attention to the header project and sends his best to everyone here. Cheers!13 points

-

13 points

-

While re-reading all 43 pages of this to answer my above questions I noted the key points to summarize for those looking to weed info out of the banter. I was looking for 5th Gen info so I might have missed something, but maybe this will save someone hours of sifting; Page 1 -General Design Specs Page 5 -Air Filters Page 6 -Prototype Install Page 7 -Fitment and Preliminary Dyno Page 8 -Install with Centerstand instructions Page 11 -Gasket details Page 13 -O2 bungs Page 13 -8th Gen Pics Page 14 -6th Gen Dyno Page 15 -First batch packaging info, weights and dimensions Page 16 - 8th Gen Dyno Page 26 -Power Commander Map Dynos Gen 5, 6 & 813 points

-

13 points

-

13 points

-

I've embarked on doing a single nut rear axle conversion to my 6th Gen/5th Gen VFR825. Mohawk did it a couple of years ago and I used his ideas but ended up with a brand new RC45 rear wheel instead of the carbon wheel like Mohawk. (Yep, I got hold of a pair of RC45 wheels that a guy has had in a cupboard unused since the mid nineties) The donor axle was a VFR400 and so is the caliper, disk, and caliper carrier. Had to get the taper spacer for the wheel and a new nut and shim, from an RC45 via Partzilla and Tyga Performance. When I started, I could not find a donor VFR400 (NC30) so I used an axle from an MC28 but found that the MC28 axle is made from lower tensile steel and it's internal profile is quite different and I felt weaker than the NC30 axle. I would advise anyone doing this mod to use the NC30 donor parts and not the MC28. The cush drive assembly is based on a Ducati quick change unit from JT and I've used a set of urethane bobbins instead of the genuine Ducati SilentBloc rubber ones. In the end this has shaved 3.0kg off the unsprung weight on the rear. The assembly drawing lists all the parts used including the part numbers and suppliers. If anyone wants to go down the same route, I've made a full set of CAD drawings and these, along with photos, are below. Disk and axle Cush Drive Assembly and Rebuilt/painted NC30 caliper Cush Drive and Axle assembled Caliper fitted All fitted up Chain guard/hugger fitted and brake hose/sensor cable bound RC45 wheel, Tyga spacer and Wheel nut Drawings Cush Drive Assembly.pdf Axle machining dwg 1.pdf Caliper Mounting Plate.pdf Cush Drive Backing Plate.pdf Cush Drive Retainer Washer.pdf Sprocket Carrier.pdf12 points

-

Spring of 1993 and I'd only had my '91 VFR for a couple months when I snapped this photo by Salish Bear totem atop Malahat Drive. Compared to many of the mountain passes I've crossed by VFR this is one of the lowest, but it is close by and offers a good view of Finlayson Arm - and, on a much clearer day, even the Olympic Range in Washington state to the south. Eagle-eyed viewers will notice the Bubba Shobert-replica Bell helmet. It looked cool, but my next helmet, a Shoei X7, was a huge improvement.12 points

-

I came across this today in a local online marketplace, thought you guys might get a laugh out of it as I did From what I got out of the ad the guy said it has a 1987 VFR700 engine that works great but would need a little work on the drive axle as it was twisting the axles he had kicking around The second picture shows the torque strip he left on the pavement. God the mind can sure go to some dark places when you get bored12 points

-

I replaced the expired ssl certificate, and renewed the software licence. Looks as if the current system will not need to be completely upgraded as I thought. Which triggered me in the first place. That is a couple day affair and a hugh pain in the ass, Linux always has something extra you have to do to get what used to work to work again when you upgrade. The problem is I just don't have the time I used to for this. I got about 100 or so messages I have yet to wade thru. But my weekend is almost over. It's been raining relentlessly so I can't even go for a ride on my new bike. I am a bit confused as to my resolve, my feeling is I don't want to give up my baby, but I just don't have the time I to put into it this place deserves. I had a few offers to take over..but I..I don't know these folks. Bottom line.12 points

-

Bravo, and I know Danno has also stepped up. Once the path forward is known and funding assessed, as others have said, lets pass the hat around to ensure that a smooth transition and an equitable departure for Miguel are adequately funded.12 points

-

12 points

-

12 points

-

12 points

-

12 points

-

I've been spending the winter scanning some of my old slides & negatives and this week I came across these two photos. First pic shows my 2nd VFR800 barely an hour after taking delivery back in Feb. 1999. It replaced my stolen red '98 and this time I opted for superfast yellow instead of yet another red bike. I'd had it fitted with a 3rd gen 8-spoke and both wheels painted a glossy pearl white. Beacon Hill park, in Victoria, is my goto spot for new bike pics. The 2nd pic shows my '91 VFR750 on it's final long ride, near Courthouse Towers in Arches NP, Utah.11 points

-

11 points

-

Hi, I put together a poster that I want to mount in my home office. Thanks to Terry for posting the PDFs so I was able to assemble it using the PDFs he uploaded. I will attach it for anyone who wants to do the same. Print it out and have it mounted etc. Thxs VFR Poster.pdf11 points

-

To all, and especially Duc2V4. I hope you don't mind me respectfully posting this excellent photo of Lance I happened to find on the web. I think it's a wonderful photo of the man and a special way for people like me who have not met Lance aka sfdownhill to remember him. I was so impressed by his and Duc2V4's tireless efforts in organizing the multiple runs of exhaust manufacturing to help out so many VFRD members, a truly great effort. A highly valued and respected VFRD member. R.I.P Lance.11 points

-

Been buildong this since start of covid, just fitted the fairings the other day. Genuine RC30 wheels, axle, sprocket carrier and modifed rear hub to accept RC30 axle fairing, fuel tank, seat unit, rear subframe, front fairing bracket, top yoke and instruments. Ktech DDS fork internals in cb1000 big one fork lowers with RC30 stantions, Nitron rear shock, Tyga stainless exhaust with carbon can.11 points

-

There is no need for mandatory fees. Mandatory fees would accelerate the end of the website, imo. The website's value comes from the information being available to everyone. Every day there is a new VFR owner, it just is a second hand VFR. Those people end up finding their way into VFRD through Googling their issues. They join the community and it expands! If we were to paywall everything it would basically island the site and that would be the end of it. The cost isn't a concern of mine at this time. Miguel is going to reach out when his time allows. I will see if I will be allowed to take over duties and keep things going. If so, I will do just that and things will continue like they always have. I do not want to implement any crazy changes like fees, etc. I'm not against making new ways for people to donate, such as a Patreon, which would allow you to schedule a monthly donation. I am happy to see people willing to contribute.11 points

-

The whole point of "saving" the site is for long term information preservation; I want someone who posted 10 years ago to be able to still find and reference their old post, not have to find out what the site is called now. Miguel would retain full admin privileges, still be the founder, just I'd assume they don't have much interest in continued participation, we'd make sure they were still able to and still have full privileges. In fact, the goal would be to make the site not feel like much all has changed. Maybe up some anti-spam measures, stuff like that, but as far as general functionality, mods, day to day, I don't see much need to start to change things up other than maybe try to jumpstart some more forum activity/events. I am willing to shoulder the financial burden as well as the technical. Fiscal assistance appreciated, but I am willing to out-right pay for it if needed to keep things running. On a technical side my plans would be to pay for whatever's needed to keep the site up for a year on the current provider, and use that year to work a transition to our own home on AWS. Try to cut those costs down as much as possible to make it financially viable long term. It'll be quite a project to transition, so having the year to do it would be the play. I've sent Miguel a DM here, posted both on this thread and the thread on Facebook. If there's interest I'm sure I'll know before too long. I really do want to save this site indefinitely, and don't mind putting in the leg work and funds to do so. The certificate expires today, May 31, so action will be needed to keep things going. If hosting continues beyond the certificate expiration, you can manually 'proceed' through the expired certificate notice. You'll have to do so until (if) it gets renewed.11 points

-

Teardown continued... without a doubt the dirtiest part of the bike was everything in the vicinity of the left radiator... it had sprung a leak in 2008 at the base of Blood Mountain... caused by a bent fan mount which allowed the fan to cut through the cooling fins as it ran. I was able to tear the bike down in a gas station parking lot at the base of the mountain with the oem tool kit. I used some steel epoxy to patch the rad and refilled the system with pure Georgia Mountain Tap Water. Over the years it developed a new leak and ended up making quite the mess. Elbow grease works wonders at loosening up that old baked on crud The frame and front end were in my way, so I took them off too I went back and forth for a bit before committing to powdercoat the frame, but I was already doing the wheels and subframe, and there'd never be a better time, so off it went. I always liked the way the black frames looked on the newer models. Wheels prepped for powder The front wheel was made by Carrozzeria and came with spacers to fit a Ducati 748 or 916 I think... it is very light at just 6lbs. It was an interesting puzzle to make the wheel work and fit properly with the R1 forks, fender and rotors I had collected. I started by measuring everything and making up cad files for the new triples, rotor carriers, and wheel and caliper spacers. This puzzle is always my favorite part of a project - taking a handful of select parts from various sources and creating a homogeneous result. I designed the triples with R1 fork spacing and a custom offset that is less than the stock 40mm. I've retained the ignition mount, ignition shroud, and steering lock in my design. I also added bar risers and a bridge to adapt a Superbike bar. I sent the fork cartridges and the Ohlins off to Traxxion for a full rebuild and revalve. The forks got Racetech G2R compression valves, Traxxion rebound valves, and Racetech springs. The shock was dyno'd and tuned after installing the new Eibach spring. I was really spoiled by the Brembo controls I had installed on my 750 naked build, so I got myself a set of RCS masters for the brake and clutch on this bike as well.11 points

-

11 points

-

11 points

-

NO FRICKIN' WAY! When a project hits a couple of the 'just one more week' cycles, it raises one's eyebrow a bit. But here is physical molecular evidence of the cause of giant ____-eating grins on the faces of 22 VFR owners: Rows of cylinders 1-2 merges alongside rows of cylinders 3-4 merges: And here is a set of production headers just the way we like our women...almost fully dressed:11 points

-

I got home Sunday afternoon after spending a couple of days in Denver, then riding to Park City, UT, spending four days hiking there and taking three to ride the 1,000 miles from Utah home. No issues with the bike, total mileage for the tour was 3,525 miles/5,673 kms. First, thanks to Tony (Didit) for organizing another great SumSum. It's always nice to see familiar faces and meet some new folks too. The rides were great, and this was the most educational VFRD event I've attended. I learned a lot watching Lee and Kevin's stator-ectomies as well as Ernest's chain resection. My bike is due for some maintenance this winter. Since reliability is important to me, I'll be inspecting (and probably replacing) my stator. The chain also has some stiff, slightly kinky links, so chain and sprockets are on the list too. I also enjoyed the parking lot Corner Carver Clinic™ with Tammy as pilot. For some reason I always like turning right better than left. The cornering tips gave me a new way of thinking about cornering so that left turns were more enjoyable (an opportunity to practice) for the rest of the tour. It was great to finally meet the famous Carver clan, and see the enthusiasm with which mini-Carver tore into Kevin's stator transplant. It was unfortunate that Kevin and Lee had to sit out the ride days waiting for parts, but the superhuman effort by Fred and Lisa to rescue Kevin from Bozeman, MT and the parking lot repairs that allowed everyone to ride home were inspiring. I hope Honda is aware of sites (thanks Miguel) and rider communities like ours and that it encourages them to continue development of the V4 800 and bring it back into the North American market. I decided to try something new on this tour. I left my trusty Nikon digital camera and Samsung netbook behind and brought only my Samsung smartphone. I hate typing with my thumbs, so I picked up a small, folding bluetooth keyboard to use with the phone. I also bought a US SIM card to avoid outrageous roaming charges. It all seemed to work pretty well and was a much smaller, lighter setup. I arrived at The Chief Motel on Tuesday, unloaded the bike, showered and headed toward The Rocket looking for other VFRD inmates. I spotted Tony and a few others walking to the brew pub next door for dinner--and SumSum4 was on! The next morning I set off with Curry, Al and Gordon but our progress was quickly halted by a lot of unprocessed hamburger meat in the road. We made our way to the site of the stoned presidents. The old west town of Deadwood, where I noticed that while the ladies were scantily clad, they seemed a bit wooden. We carried on to see more stuff carved out of mountains (you'd think they could find an easier medium to work with), the Insane Equine: On the ride back to Custer, Cogswell wanted proof of where he takes his moto-touring holidays: The next day Cogswell and I decided to see the Needles: And revisit the presidents to compose them in a shot with something truly impressive 😜 Not VFR-related (but I used the bike to get there!), a few shots from the back end of my trip: Ski jumpers practicing at the Utah Olympic Park (Look closely, there's a little guy inverted over the water. This may be where the phone lets me down as a camera.) Park City historic downtown. And a few beauty shots from the hikes in and around Park City. Ski runs. Park City from the hills surrounding the Olympic Park. Bonnie Lake in the Uinta National Forest. Provo Falls. Wasatch mountains from 9,500 feet, about three hours into the Mt. Timpanogos hike. As a nice lady in a tiny (one pump) gas station in Oregon told me: "May you never ride faster than your guardian angel can fly!"11 points

-

Once again, Tony arranged an amazing meet. Huskysooner and I left NE Kansas at 0500 to meet Panamawing in Nebraska. We then headed west to our first destination. There is a street in western Nebraska that I share a name with and I've always wanted to visit it, but never had the opportunity. Heading north we crossed the Sand Hills of Nebraska.... a beautiful but desolate place with little sign of human presence. It was here that I first noticed I was having problems. I thought I had lost my speedometer drive nut as my display showed erratic speeds and mileage stopped rolling up. Unfortunately this was not the case, apparently the pulse generator or electronics that read it have low tolerance of low voltage. My stator was failing. At Alliance, NE my bike died when we pulled in to fill the tanks and would not start. A quick check of the battery showed it sitting at 9 volts. Huskysooner jumped on his dry clutch Ducati and rattled off to buy me a new battery. I disabled all non-critical electric circuits. A check with the a meter showed that the bike could (just barely) maintain 12 volts at 5,500 rpm. So off we went to Custer. Me with no lamps. At Custer, Huntingguns had returned from saving Cageless in Seattle from his burned stator. He had already started the process of getting a pair of stators on order. I was the lucky recipient of his foresight. Even with the head start, much of my meet was spent waiting for the FedEx truck to arrive. While I waited, I took a couple of small hikes around the area, taking in the history and scenery. Custer viewed from high above. I was also in the right place at the right time to help in the recovery of Shade's bike when he suffered a broken chain. A big thanks to Dragonfly and Q Dawg for providing the truck needed in this effort. It was like a quick response team jumped into action when the call came in. As soon as FedEx arrived I got to work repairing my bike while Mini Carver went to work on Cageless' motorbike. For those who showed interest in my mini ratchet set google <Wadsworth Super Deluxe Mini-ratchet set> As can be expected with any parking lot repair at a meet, there was a good size "cheering" section with all hands at the ready. Other than stubborn gaskets, all went well on both bikes. Not to be outdone, I burned my stator (right) to a slighly toastier state than Cageless. My bike had 55,xxx miles on it at this point. (New - 24 vac @ idle, 62 vac @ 5500 rpm) The evening festivities were entertaining and fun with Didit keeping everyone in stitches with Corner Carver's help on occasion. (They are not quite the team that Timmy and Carver are, but there was no shortage of things to laugh at.) My multi-meet roomate, GSwanson has moved from his sixth gen VFR to a BMW S1000 XR. He choked me up when he made a presentation of his Sargent saddle to me. I can tell you that it is a huge improvement over the stock seat as witnessed by the comfort I had on my 750+ mile ride home. I was greatly honored when CVVFR arranged to gift me a flag signed by the Canadians. It is a huge honor and a life treasure that I will display proudly. I can't even begin to explain how much this gesture meant to me. Thank you Canadian crew!!!!! At the advice of Axel_7 and Tammy, I was up before the sun the next day to take in the local sights on a foggy morning before the crowds could settle in. It was great advice as I had everything to myself. Following the ride Huskysooner, Panamawing and I joined forces again for the ride to our homes. Led by Panamawing, we took in a few more sights on our way out of Custer. We were able to witness the overnight/day shift change at the bison roadblock when the bison going off duty was relieved by his mate. As one wandered off the road another quickly stepped forward to maintain the post. SumSum 4 !!!!!!!11 points

-

11 points

-

11 points

-

Twelve and a half years ago I began to modify a CA-spec Y2k VFR800Fi: Today, under vastly different circumstances and with somewhat different goals I have begun to modify its UK cousin, a Pearl Tahitian blue '01 VFR800Fi. I actually haven't worked on or ridden bikes for several years, for various reasons which all sound like excuses now, but that ends today. It's a good place to start. I acquired this bike ca. 2016, with low miles and apparently no damage (we'll see about that...) Over the years, I also acquired a load of parts for it, such as: SP2 forks, SP1 front wheel, SP1 bottom yoke, 929 top triple clamp, Tommaselli adjustable clip-ons, 8-spoke rear wheel, SH847 reg/rec, GiVi and SW-Motech luggage, Nitron shock, VFRD headers, Harris hugger, 6th gen rear cushion bracket, Sato adjustable rearsets, 6th gen ABS rear caliper, windowed clutch cover, xenon projector headlights, etc. Sadly, no supercharger or custom underseat exhausts this time...for now. Where to begin... Mmmmm. I do love cleaning years-old chain spooge... Wish me luck! Ciao, JZH10 points

-BFP.jpg.e2d78ae0cad4313237c39d4fbdf88f5b.jpg)