-

Posts

4,453 -

Joined

-

Days Won

122

Cogswell last won the day on January 13

Cogswell had the most liked content!

About Cogswell

Profile Information

-

Location

Riot City, Oregon :(

-

In My Garage:

1999 VFR

2008 VFR ABS

1995 VFR - gone but not forgotten

Cogswell's Achievements

-

First ride of the season and the side of the road.

Cogswell replied to trmoyer's topic in Fifth Generation VFR's

I used them about a year ago, still in business then. The owner (I don't recall his name) has had to step aside and another person is answering the phone now. IIRC the cost was $135 including return shipping, but always good to call and get a quote. You may need to leave a message. I've used them several times now and have been happy with the results. I've also done the stator / flywheel swap to my 5th gen motor. It did help the output - using the 847 I get charging at idle when the fan is running - that was not happening with the stock 5th gen stator / f.w. If doing the swap, you >> must << use the bolts from a 6th gen stator to secure the stator in the 5th gen cover. While the 6th gen stator does fit in the 5th gen cover, the 6th gen stator is slightly thinner, and thus the 5th gen bolts will bottom out in the blind holes before securing the stator tight. One would think that given the high degree of commonality between 5th and 6th gen engine blocks, the shape of the stator covers would be the same - but that is not the case. So, the 5th gen cover must be retained - just the flywheel and stator will swap over. -

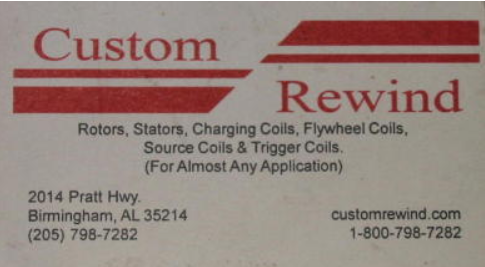

I would recommend that you hang on to your 5th gen OEM stator. If the Chinese stator disappoints, you can always have the OEM stator re-wound by Custom Rewind in Birmingham, AL. A number of members here have used them and I've never seen one complaint. I've used them twice - they've done a great job for me. The last IIRC was $135, you pay shipping to them, return is included in the cost. Call 1st to get up to date pricing. You may have to leave a message and he'll call you back.

-

Nice collection. The tank came our great. It's too bad owners allow that to happen. But that makes them cheaper to buy!

-

If you used the breaker shipped by Roadster with your 020, it's almost certainly the auto-reset type. IDK why he uses those. IMHO they're crap. I ditched mine for a 30A replaceable maxi fuse. Also, if you do replace the stator, swapping to a 6th gen stator and flywheel is a nice upgrade. Prior to doing mine, at idle when the cooling fan kicked on my VM was reading below battery voltage - and I have LED headlights, so my base current draw is very low. My stator is (was) low mile and checked out fine. After the swap I get around 13.5 with the fan running and 14.5 (as before) going down the road. A couple of things to note if doing this: 1. Although the 5th and 6th gen blocks share much in common, stator covers are not one of them. You'll need to retain your 5th gen cover. 2. The 6th gen stator will bolt right in directly to the 5th gen cover, however the stators are NOT the same thickness. IIRC (it's been a year now) the 6th gen stator is slightly thinner, thus the 5th gen bolts will bottom out in the blind hole before drawing the 6th gen stator down tight. DO NOT keep tightening the bolts b/c the stator remains a bit loose lest the threads strip, ruining the cover. Get some slightly shorter socket cap bolts and torque them to spec. Do some measuring to satisfy yourself that you've accounted for any differences. 3. To get the 5th gen flywheel off, best bet is to use an impact gun. Rent or borrow if necessary. Holding that little beastie in place is a real PITA, even if you do have a strap wrench or similar to place around it. It might be doable with 2 sets of hands, dunno about that - I did mine solo. Impact gun makes quick work of it. I kept it on the lowest setting that would remove it to minimize the shock load to the crank. 4. If the flywheel is a no-go coming off the crank snout, go to an auto parts store and pick up a 20mm X 1.5 oil drain plug. It should thread easily by hand in to the center of the flywheel - do not force it. If not, check the plug threads or possibly you have the wrong size. Once it bottoms, use a wrench to tighten, then the flywheel should pop right off. The plug should cost $2 to $3, not the $20+ on Amazon or $$$$$ from Honda. 5. The 6th gen flywheel has two flats on the hub that I could fit a large adjustable wrench on (which the 5th gen flywheel lacks). That made applying the 76 foot pounds to the bolt a breeze. So for me this became a one way trip - once the 5th gen flywheel was off I was committed to the 6th gen, as I had no way or re-torquing the 5th gen flywheel. I do not recommend re-torquing the flywheel with an impact gun. That's one of the critical fasteners that needs to be correct - close may not be good enough. 6. The "V" shaped grommet on the 6th gen stator wiring was larger than the V groove in the cover - it required some trimming. Since I had the new stator re-wound, IDK if that was because they used something different than OEM or if there's a difference in the two covers which need a different size grommet. Regardless, I did some trimming. My trimming work wasn't perfect, so I used a skim coat of silicone and have had no leaks in the 1,000 miles I've been running it. 7. If your gasket breaks apart when removing the stator cover, be sure to use only plastic scrapers. Use of a steel scraper will surely scratch the aluminum and you'll have leaks. After 25 years, removing the gasket was difficult - the best thing I could find to soften it was acetone, which actually did a pretty decent job. From what I hear, the EPA has pretty much neutered most gasket removers we have today. Gaskets are NLA from Honda (as are 5th gen stators), but there are sources on ebay that will do fine. I applied a thin film of grease to the gasket to make future removal easier. When doing this swap, I followed the lead of others that have also done it. I was skeptical - I did a lot of measuring to see if there were any clearance issues with the 6th gen flywheel. I used modeling clay to check for clearances whilst assembled and applying bluing to various places that looked like could be problematic. Everything came up ok. Once assembled, I turned the engine over without starting it, the took it back apart to see if there were any signs of rubbing, scraping or interference. All looked good. Be sure you are satisfied that all is good before the 1st startup. Overall I'm very happy with it - the output is definitely improved and so far it's been a seamless swap. YMMV

-

No matter how one does it, highly recommended to have one of these - esp on 6th gens which seem to eat statros like chips at a Super Bowl party. There was a thread on here 10 + years ago of how owners had mounted these on all gens - there had to be at least 20 + ideas people had come up with. The creativity was amazing. The one presented here is very tidy looking - nice job.

-

Out of gas? How long has the fuel gauge been blinking? Just curious, every 6th gen I've seen (in the US) has a small, round block off to the left of the ODO trip reset button. Yours appears to have a plunger type of switch poking out. Pardon my ignorance - what is that - OEM or something added on?

-

Hi Grum. Good points all. My experience with it was somewhat different and maybe unusual. By 2020 My VTEC at 10 years was about double the recommended interval so I dug in to a valve adjustment. I also made my own stopper pins for the VTEC buckets. I ran through the procedure and came up with measurements showing all 8 VTEC valves were way too tight along with a handful of the other 8. I had ridden it normally, maybe seeing 7k+ rpm maybe 15% or less of the time - by no means hammering on it. The VTEC exhaust ports were minty clean, showing how much less they had been exposed to combustion byproducts vs the other 4. My initial reaction to my measurements was "I must have made a mistake". I put it all back together, ran it and it seemed to run and sound fine, as before. So I took it apart again, meticulously going through the procedure, measuring everything again. I got the same numbers. Hmmm. So I once again put it all back together, ran it and considered its fate. I finally called a buddy who is a 35+ year A&P mechanic and long time Honda bike nut who's worked on more Honda bike motors than I can count. I offered pizza and refreshments to him if he would come over and see what he got for my valve clearances, making no mention of my prior results to avoid prejudicing him. I got everything stripped down so that all he need do was remove cams, make measurements, etc. When the day came, he went out in the garage with the printed procedure in hand and went to work while I went off running errands, etc. When I returned with pizza, he walked in and announced "ALL of your VTEC valves are tight. They all have some clearance, but all are well below spec". So it went back together for the 3rd and final time before being replaced in 2020 with GDC's. While unusual and not common, I seem to recall someone else on here having that same situation. While the logic of the VTEC getting less use is very sound, there also seems to be outliers defying convention and I might say, explanation. The cheapest VTEC buckets I could find were $32 each (none were able to be swapped to another position), so the cost of it was not much less than doing the motor swap. As always, YMMV.

-

I pay about $320 / yr for my 6th gen. I have multiple vehicles and home policy tho - maybe that helps with discounts.

-

So great to see a 3rd gen!

-

How does (or does it?) this work with the rear wheel from a SSSA? From the videos I've seen it appears to need the wheel bearings to keep it positioned. I've been using a Mojo lever and Marc Parnes balancer with good success. I've changed tires for friends - not too bad a job with the right equipment - a minor nightmare without. If there are any tutorials on using that tool on a SSSA rear wheel, would love to have a look at it.

-

From my experience, 5th gen R/R's from the factory were suspect - mine didn't make it to 10,000 miles before giving stray voltage output. Declining voltage as rpm increased was one of the symptoms. Regardless of whether you use the one you have in the shed, I'd be inclined to replace it.

-

What were the real differences between the 5th and 6th gen?

Cogswell replied to fabio222's topic in Sixth Generation VFR's

This was the "what have I done" moment, after the VTEC was lowered from the frame with the 8,000 mile 5th gen motor waiting on the pallet. The cam cover is removed b/c I had already been in there adjusting the VTEC valves and it also gave me the extra clearance needed to clear the frame once lowered on the jack. Once it was back together and running, going for its first short ride around the block left me barely believing it was actually working. I read where others that have done this sit the engine down on block(s) and then lift the frame off and roll it away like a wheel barrow, leaving the engine behind. On top of the 2 step ladders is a thick wooden beam and ratchet straps. Either way works, this is just mine. Clearly this is quite invasive surgery, but very doable for any determined DIYer. Like any project, bag & tag fasteners, label, stay organized and torque to spec and you'll be good. -

Knee down, toe about to drag, and the peg feeler still has a way to go before it touches. This one still has more in it re corning before it's at the limit. These bikes (as most modern motorcycles) are more capable than most of their riders (including me!).

-

If you're interested in how one will do on the track, have a look at this video of John McGuinness riding a 5th gen at a track day. This one has 100,000 miles and a luggage rack. Note that he's passing many sportier, more powerful (probably liter) bikes. They likely pull away from him down the straights, but in the corners he makes it all back and more. https://www.youtube.com/watch?v=bMWXwsGUGM8