-

Posts

4,101 -

Joined

-

Last visited

-

Days Won

128

Grum last won the day on December 5 2024

Grum had the most liked content!

About Grum

Profile Information

-

Location

Australia

-

In My Garage:

2014 VFR800F

Recent Profile Visitors

Grum's Achievements

-

"Sprockets still look good but as they say sprockets and chain at the same time." l really believe this is purely based on old school thoughts and technology. Perhaps its based on a worse case scenario being, salty slushy roads, poor tension, poor cleanlines, cheap and nasty chain, poor maintenance, etc. My 8gen has now done over 100,000kms on the OEM rear sprocket, the front was replaced at around 70,000kms. I know you're the type of owner who takes care and pride of his bike so I'd be shocked if you're needing a new rear sprocket at such a relatively low mileage. I've never experienced any premature chain wear, transmission noise etc. to indicate my sprockets needed replacing, also the visual look of the sprockets showed no signs of wear. BUT.....As always YMMV.

-

This might answer your questions.

-

Leaking Fuel Tank and breather hose issues

Grum replied to Bobby2024's topic in Eighth Generation VFR's

Hi Bob. Just a bit of info, food for thought..... - For sure, your high performance Ford Focus required Premium Fuel. However your VFR doesn't. - Your Australian Owners Manual states "Your motorcycle is designed to use 91ron, or higher". The "or higher" is not strictly correct as the VFR is not designed to reap any benefit from the higher octane fuel, nor does it need the higher anti knock stability, however, no harm done should you chose to use it. - Myself and other members have done some economy test runs with Premium and Standard fuels. On four VFR's my best economy runs have all been on 91ron and absolutely no perceivable benefit in performance with Premium. Keep in mind that the VFR does Not have an Anti Knock Sensor, so it's unable to take any slight advantage in tuning to the higher octane. Interesting, the energy values between Standard and Premium fuels are virtually identical. - Picking up "bad fuel" is generally Not the fuels' fault, more so the Service Station's tank and pump cleanliness and maintenance practices. - I was once told by a sales guy at a Yamaha Dealership that our 91oct fuel "is shit" Oh really I replied. So given the enormous volumes of 91oct fuel sold when compared to Premium Fuels how come I don't see thousands of cars on the side of the road with fuel injector issues etc. AND any major car or motorcycle manufacturer that knew Australian 91oct was "shit" would Never specify its use in their vehicle's. While the sulphur content in 91oct can be up to three times that of Premium, its only the Greenies and Fuel companies that prefer you to use the environmentally cleaner Premium and Ethanol blends - Beware the fuel companies advertising campaigns in luring people into so called benefits of using Premium when its simply not required or specified for their vehicle. Premium Fuel = Premium Profits for fuel companies. - With four VFR's I've owned and the fuel injected numerous cars both current and going back to my 1993 ED Falcon, ALL specified 91oct in their Owners Manuals so all were fed a diet of 91oct and have yet to experience a single Injector or Fuel Pump issue. I do admit to very rarely throwing a bottle of injector cleaner into the tank, have no idea as to any benefits of doing that! at least it might have a good placebo effect! - Can guarantee your 8gen will run perfectly on 91oct, and I certainly stick with the major suppliers eg BP, Shell, Ampol and Caltex. - Given the enormous turnover volumes of 91 compared to Ultra Premium 98. You might be assured of fresher fuel with 91oct. However, if you're still happy with Premium, fine, whatever floats your boat. You might still make a good saving in at least going from 98oct to 95oct. As always and especially with Oil and Fuel - YMMV. Keep us posted as to the Fuel Tank repair - hope all goes well. Cheers. - -

Leaking Fuel Tank and breather hose issues

Grum replied to Bobby2024's topic in Eighth Generation VFR's

Yes normal. Most 8gen owners hear it. Its just the tank pressure venting via a small spring loaded valve within the filler cap, the valve flutters as it vents, it can sound almost like the fuel pump is priming. I often get the noise after a ride and park the bike in the garage, as the engine heat warms up the tank it becomes quite noticeable if you're near the bike. Pop the fuel cap open and the noise instantly disappears. -

Leaking Fuel Tank and breather hose issues

Grum replied to Bobby2024's topic in Eighth Generation VFR's

Hi Bob Yep that's exactly the pic I was going to post for you. I'd love to know the dealership's reasoning for suggesting you use Premium 98oct !!! Absolute waste of money and with no fuel economy benefit. No issues with mine after 100,000kms on standard 91oct. Three previous 6gens all on 91oct again no issues With low fuel in the tank. Have you tried using a bright light and inspection mirror looking in through the filler neck, you might see the leakage issue. Just a thought. I can't help thinking that perhaps the dealership may have caused the leakage issue! It's very easy to knock the tank off any strut arrangement in the maintenance position. It may have fallen and smashed into a tool or whatever sitting under the tank while they've been working in the airbox area. What suburb of Melbourne do you live? -

Leaking Fuel Tank and breather hose issues

Grum replied to Bobby2024's topic in Eighth Generation VFR's

Hi Bob. Looks like the original position of the hose was incorrect! and where you have it now IS correct. It also matches the hose routing per the Service Manual. See attached my 2014, hose in original position. Provided when lowering the tank the slack is taken up I've never had a problem with tank venting, after 100,000kms. Due to the internal spring loaded poppet type valve in the fuel cap, you should only ever experience very slight pressure or vacuum when opening the filler cap, the emphasis is.......... Slight.. Very strange to hear of a hole in the tank of a 2016 8gen. Seeing you're in Melbourne, trust you completely avoid Ethanol blended Fuel? -

My VFR800 mod related questions and thoughts.

Grum replied to RdChinoy's question in Modification Questions

No, VFR is 1-3-2-4. -

My VFR800 mod related questions and thoughts.

Grum replied to RdChinoy's question in Modification Questions

And since Honda has removed the Variable Intake (Flapper) system from the 2016 onwards 8gen. I decided to do the same to my 2014 8gen just to clear some under tank clutter, can easily re-install all the stuff if needed. Just like you Terry, completely unable to detect any form of negative effect, performance, fuel economy, fuelling, throttle control are all as good if not better than pre removal. Surely, the cleanliness and air flow through the airfilter would be more important, than any possible adverse effect of removing the system. As always YMMV. -

NEED HELP from one of you VFR wiring guru’s… PLEASE!

Grum replied to LILjoeSCARGAP's topic in Sixth Generation VFR's

Blowing Fuses? YES = You have a short! NOT blowing fuses? Blinkers, Headlights, etc. work normally = You are chasing Moonbeams! Follow the wires you're measuring. If they go to relay coils or globes that have a Ground wire on the other end, there's your answer. For Ground continuity at the Blue 18P connector your main concern is the Green Wire having continuity back to the Negative terminal on BOTH sides of the Blue connector.- 17 replies

-

- electrical

- wiring

-

(and 8 more)

Tagged with:

-

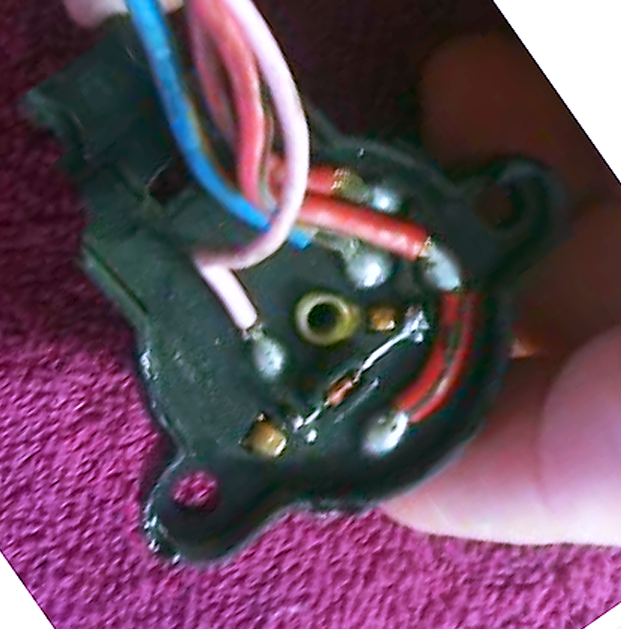

*SOLVED!* USA VFR800 won’t start after ignition change

Grum replied to Frey's topic in Sixth Generation VFR's

The Pink and Blue/Orange wires should NEVER be joined to each other! Does the underneath of the original Ignition Switch look like this? Suspect you are using the wrong diagram of your Ignition Switch! -

Hi Michael. Great news, have to admit, those Champion Plugs didn't give me a warm cozy feeling! Glad the NGK"s have done the trick, proof will be in the riding. The other good thing regards the NGK's is a 50,000 Mile life. Found this interesting snippet of info regarding the use of Non Resistor type plugs which the G59C's are... "Use of non-resistor plugs in vehicles that call for a resistor type can result in rough idling, high-rpm misfire, and abnormal combustion." Just some info regarding 5th Gen SV settings as the Service Manual is confusing, here are the ideal settings.... 1 = MASTER 2 = Match to No 1 3 = 20mmHg MORE than 1 4 = 10mmHg MORE then 1 Good Luck hope it all works out. Cheers.

-

Yeah an LED is not suitable for rhe Fi Light. Its the only one in the dash that needs to be an incandescent bulb. The ECM provides an electronic ground switching for the bulb and the LED doesn't match the circuit impedance.

-

Quick question about continuity, info please?!🙏

Grum replied to LILjoeSCARGAP's topic in Sixth Generation VFR's

Might be worth unplugging both ECM connectors, check for any corrosion on the pins and sockets. Give them a good spray of Electrical Cleaner. What ECM do you currently have installed? The original or spare? Are they both exactly the same part number and version? Can you confirm by probing the ECM wires that all Grounds being the Green/Pinks and the Green have good continuity to battery Neg. And you are getting 12v at the Black/White wires at the ECM. -

Quick question about continuity, info please?!🙏

Grum replied to LILjoeSCARGAP's topic in Sixth Generation VFR's

Ok, sorry but I have to ask this! When checking for spark Are You Properly Grounding the body of the spark plug? The reason I ask this is the I've just done some continuity checks to Ground of the head covers and because of the external protective coating on these there is no continuity, same if I place a probe on the clutch cover. So if you were just grounding the plug via the external surface of the head cover you may NOT be getting a spark. Make sure the plug body IS properly grounded when doing a spark test. Black/White wire voltage drop. Work back from the Ignition coils, check the voltage at the ESR, then the incomming voltage on the Red/White wire to the ESR, then measure the Red/White wire at the 18P Blue connector are you seeing the same or different volts on both sides of the blue connector, now follow the Red/White wire all the way back to Main Fuse B 30amp measure the voltage on both the test points of the fuse, probe the Inline connector for the fuse are you seeing any voltage drop there. Somewhere along the line you should establish a point at where you are dropping voltage. Follow what I'm saying here via the Wiring Diagram, Note as you work your way closer to the Battery your voltage will naturally rise, what your looking for is a sudden increase towards battery voltage the might highlite a bad connection. Good Luck. -

Quick question about continuity, info please?!🙏

Grum replied to LILjoeSCARGAP's topic in Sixth Generation VFR's

In your other Post.... It was suggested to try this. You gave no report back! Have you bothered to check this? "Try the spark test again with the Sidestand Up, does this make a difference? The ECM Must see either the Ground signal from the Neutral Switch (via the Neutral/Clutch Diode, then the Green/Red wire at the ECM) OR the Sidestand Switch UP (Green/White wire at the ECM). No Ground detected = Ignition Disabled. You also want to be sure that the common Ground wires for the Ignition Coils measure GOOD continuity back to the Battery Negative terminal, AND that you measure good battery voltage on the Black/White wires for the coils." Seems a bit strange you've gone from intermittent fuel pump ops and low fuel flow, to now an Ignition fault!