-

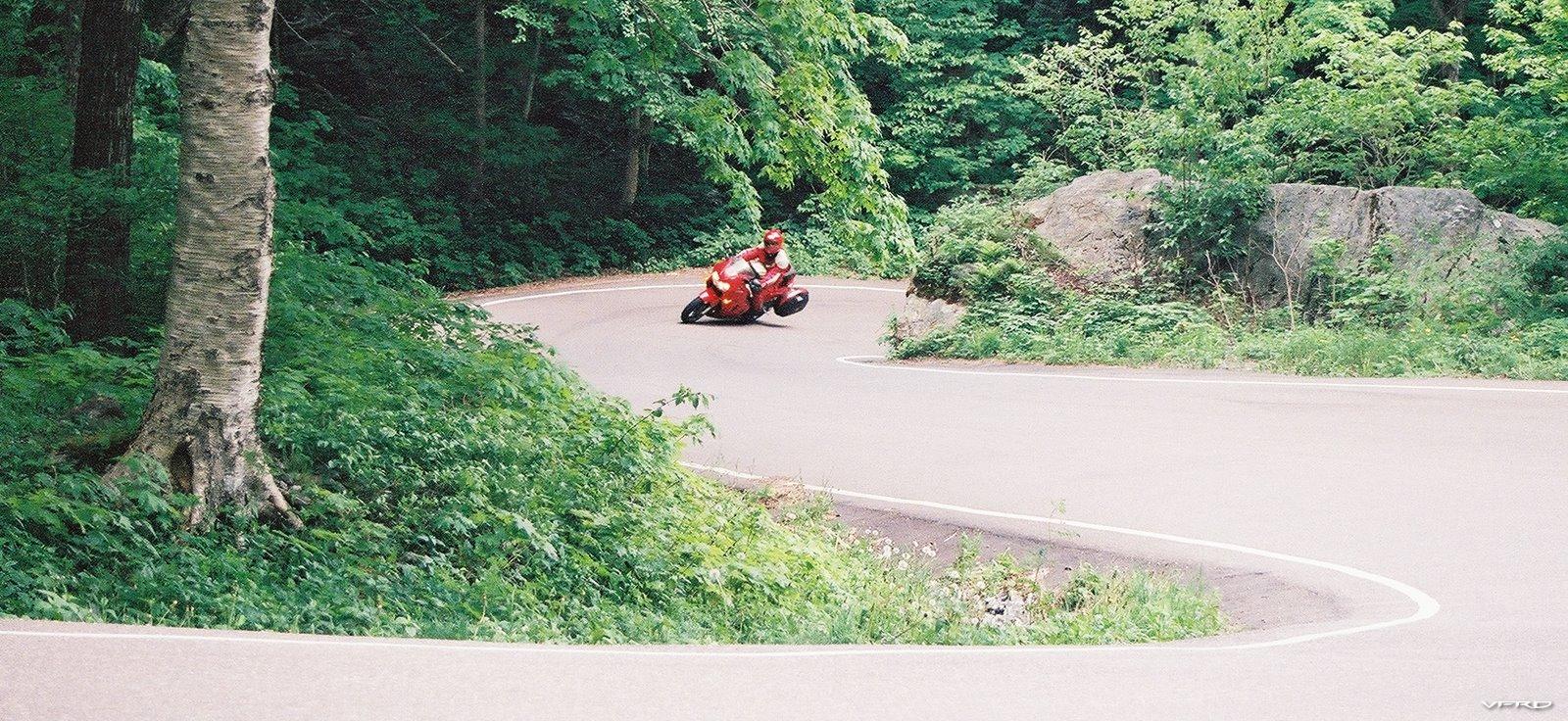

Featured Gallery Photo

Tim A carving through Smuggler's Notch

Tim A carving through Smuggler's Notch

VT-108 at Smuggler's Notch. Unbelievable curves!

Credit

Photo by Kirk A.Copyright

© 2018 Kirk A.

All Activity

- Today

-

I never needed it on all my RWU forks either but the USD design is quite a different beast. I have usually been able to catch the underside of the locknut on top of the spacer while I wind a cap on. I buy a lot of bits like these on Aliexpress; I know they aren't always the best quality but they are cheap and usually travel swiftly, and it is a whole lot easier than trying to find similar bits locally.

-

I need to get that forked plate, or make one. I manage, but I could manage easier.

-

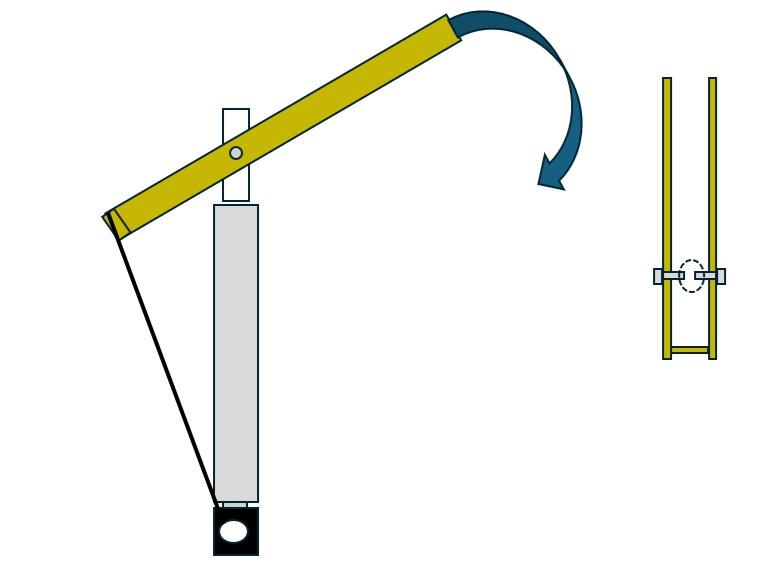

Yeah, did all of that, thanks for the advice; used insulation tape wrapped around the stanchion where the upper bushing sits, and coated the new oil and dust seals with red rubber grease. This time around I have used some fancy SKF seals, and I have spent a good amount of time with the 400-grit paper on the pits. Installation was really easy using a neato fork seal driver that I bought from Aliexpress ($22!). I re-used my home-built fork spring compressor; it's a little agricultural and consists of two 900mm lengths of 90x22 decking timber with a 50mm joiner length screwed in at one end to make a U; then two bolts are screwed in about 300mm from the joiner projecting in to catch the holes in the plastic preload spacer. I put a ratchet strap through the axle hole and tie it around the joiner and ratchet that until the wood points up. I now just push down on the ends of the wood and can easily compress the spring to reach the damper rod bolt. I did buy one of those handy forked plates that slip under the damper locknut and hold everything still so you can refit the fork cap which makes this less of a three-handed task. I also bought the supposedly correct tool to compress the springs but my trebuchet design is much easier to use!

-

Nothing wrong with the look of the staintune. Love the sound.

-

Yeah, I knew of the "all models using this part" list but that only works with identical part numbers. Like the slave cylinder compatibility, the number of similar to identical parts with different numbers out there is unknown. Another I do know is the shifter shaft oil seal. Different numbers for the VTX and VFR, but it's the same size seal for both.

-

-

Man Cave? No. Man hangar.

-

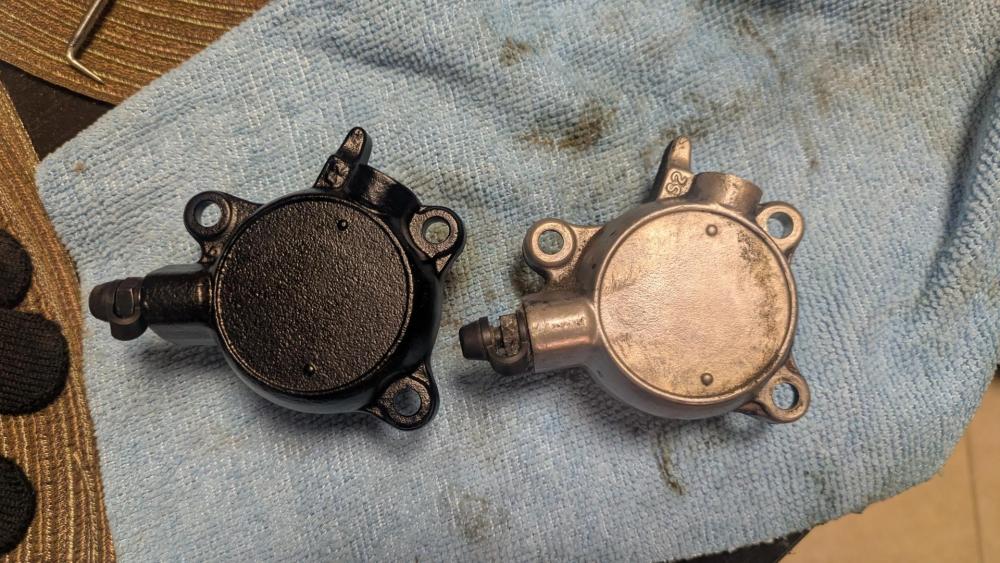

One of those... I wasnt really looking, but this one hit me in the face... Off the Valk forum, I damn near stole these rotors.... (Valkyrie and VFR rotors are dimensionally identical) Braking Brand (Brembo owned, subsidiary) decent shape.... Now to decide whether to use or not.... This one.? Or this one ..OEM? AIIIIEEEEE! 🤪Gonna have to kill quite a few IPAs and maybe some Stouts to decide this one.... 😲 Cheez and beerz (hic)

-

Partzilla's website allows you to look up parts and then see which other models they fit. The complete clutch slave is common to the CBR1100XX, VTR1000F, RC51. The slave piston is common to 1500 Goldwings from 89, ST1100. The water pump is shared with the CBR900RR. I found out (in desperation) that the throttle tube is the same piece on my 99 VFR800 and my '15 VFR1200, but the parts manuals don't show that due to the difference in grip design that can be model specific. Paint colours cause the same apparent incompatibility.

-

My experience with stanchions like that is if your fingernail catches on it it will take out a seal, but fine polishing will make some pretty large pits acceptable. As mentioned use protection, and lube when installing the seals over the top of the tube. I use Ziplock bags or multiple layers of plastic wrap whichever is handy. Packing the space between the oil, and dust seals with grease will also help as any debris that gets past the dust seal gets suspended in the grease.

- Yesterday

-

Not a sixth gen, but I stumbled across some shared parts with the VTX1800. The slave cylinder for the monster twin and the fifth gen appear to be the same other than a coat of black paint and price difference (VFR one is pricier). The slave on my 1800 started weeping, and I was all set for a soft parts rebuild but there's some hard crud in the piston bore that needs delicate removal. The 1800 slave cylinder looked really familiar, and I remembered I have a stock of VFR critical spares and pulled a new slave assembly and piston off the shelf. Everything looked identical down to the casting and bolt pattern so I threw it on the VTX where it's been for the last 30K miles. This means when I get off my duff and toss the VTX assembly in a parts cleaner and replace the soft bits it'll go on a shelf. If I need it for the VFR I'll grab a can of Rustoleum black enamel and give it a coat. If you look at the price difference between the two that's one expensive Honda paint job for the black finish. No concern for the black cylinder installed on the VTX cause all that crap is covered by decorative chrome side cover.

- Last week

-

Thanks Mike; the divots aren't really any different to a rock dent and I've dealt with those before without leaks so I was disappointed with this outcome. I'm trying to avoid spending too much more money on Earl, as far as I know this is the last mechanical issue that I need to deal with (famous last words...).

-

I would give it one more go with a new seal knowing that you're not installing/removing it multiple times over the top of the tube and being extra careful by wrapping the lip and groove. Then you will know for sure if you have to source another tube. and it might buy you more time as it may not leak as bad if it starts to leave a ring.

-

I spent a bit of time on my leaky fork last night. As received the bike had spent 3 years outdoors, maybe somewhere coastal based on the corrosion. On the hidden inside of the left stanchion (behind the mudguard and adjacent to the disc) there was a decent amount of corrosion; the right leg, and the exposed part of the left leg were not near as bad and my assumption is that salt spray was being washed off by periodic rain in those areas. As I was doing the rebuild I carefully filed off any protrusions and then polished further with 400-grit emery paper which has left no "lips" that can catch on the seal but there are a handful of divots that you can just catch a fingernail in at the right angle. The little black specks on the chrome above the obvious oily line are all that is visible of these divots. I was hoping to fill these with metal epoxy, but after application and then sanding back the divots are still there, maybe just too small/shallow to have enough adherence to the putty. So I have given everything another good emery paper rub down, and will hope for a better result with a new seal. I am not ruling out that I may have caused some damage to the last seal when I pushed that over the bushing groove as I know I did that a few times as I was figuring the fork out, so I will take extra care (and wrap the sharp parts in insulation tape) when I fit the new seal. Plans B and C are to buy a used fork (there is a local breaker that has a decent pair for US$320) or I can get a new part ex Webike for a little less money, or there are replacement tubes on eBay for about US$230 (but that will require disassembly of the axle/brake mount from the old tube, which looks a bit challenging). At this point I am inclinded to reassembly with the old part with new seal, and some finger crossing.

-

With a big engine, torque is where it is at, and it gives you the ability to be a bit lazy with gear changes. My 6th gen 800 certainly likes to be kept "on the boil" above 7k which is fun when you are in the mood but it can feel a little flat otherwise. I also have a Yamaha MT-10 and love the character and punch (and a great riding position) but I'm not brave enough to give it full throttle as you are perched on top like an organic speed brake! I did get it remapped which only improved the low end and throttle response, and it is a blast to ride on twisty roads and makes the best sounds (this side of a V4) as long as you don't mind (or care about) the Yamaha "tick". I think Yamaha are missing a sales opportunity with the MT-10 as it just a larger tank, hard luggage mounts and a half fairing away from sport-touring heaven, but it might canabalise sales from the Tracer 9. Personally I think the two engines give two distinct characters.

-

And the bill for heating that place in winter came in.....

-

Same torque, less power but the torque curve is reprofiled for more lower down. Red line is around 9k rpm (I'd have to go and check for an accurate figure) but yr right, I don't recall ever finding a road long enough (or balls big enough) to redline the 1200F so it's all a bit academic.

-

I don't think I have revved my 1200 past 8000rpm yet and probably seldom will. Is the power on the X notably toned down at the lower end of the range?

-

VFRD Mission Statement

For owners of the Honda Interceptor and related Honda V4 motorcycles, for the purpose of mutual help concerning safe riding, maintenance, and performance of their motorcycles.

Rules of the ride - No one goes to jail, and No one goes to the Hospital.

Contributions - VFRD is a member supported website with no commercial advertising.

-

Forum Statistics

-

Total Topics26.6k

-

Total Posts363.1k

-

-

Who's Online (See full list)

-

Member Statistics

-

Upcoming Events

No upcoming events found -

Latest Classifieds

-

Top Downloads

-

-

Popular Contributors

-

Blog Statistics

-

Total Blogs116

-

Total Entries345

-

-

Gallery Statistics

-

Blog Entries

-

Blog Comments

-

By vfrpilot28 · Posted

I enjoyed reading this and seeing your story. For the love of motorcycling! -

By interceptor69 · Posted

Oops. I do believe I know how to post YT videos or they wouldn't be on YT. However I may have screwed up copying the link to the playlist. Thanks for the helpful comment. -

I think that you might not know how to post videos. You're in your YT studio in these links. You need the link to the actual video.

-

Most Contributions

.thumb.jpg.6b9488d9849fb7037caa4c17228db2ab.jpg)