Leaderboard

Popular Content

Showing content with the highest reputation since 07/02/2025 in all areas

-

Lucked into a crazy deal on a one-owner 1998/5th Gen yesterday and want to keep up with tech stuff. The gent (77) bought it new in 99 and has cared for it beyond what most people would, tons of documented preventive maintenance over the years and only 1k miles added to the clock since Covid. New to VFRs but not bikes in general, I've owned many brands since 2006 (drank the HD koolaid up until then). I can already tell that the factory seat and I will not play nicely together, otherwise I'm digging it!5 points

-

You want to be able ride them easily. If not, look what our (deceased) club president did to his livingroom. https://www.motor.nl/video/motormuseum-in-je-huiskamer/3 points

-

Well thanks to this thread, and Frogger and TT, I absolutely broke the bank last week and ordered a $63 CarPlay unit made in China by Camecho. Just finished the install so haven't ridden it yet but I have to say it all works quite nicely. Here's the (few) Cons, then the Pros, mostly as compared to my new doorstop, the 15 year-old Garmin Zumo: Cons: -The Zumo showed elevation, which was kind nice, but I'm sure I can find an app... -The Zumo was a quick (one second) disconnect. On this unit you have to unscrew the waterproof connection, which is on about a foot of cable attached to the unit. And when you screw it back on the inner piece must be aligned rotationally perfectly, probably not easy in the dark. But then again, it only costs $63, maybe I'll never remove it... Pros: -Well, it's CarPlay. I'm iOS, but even if you're Android you'll know that it does pretty much everything CarPlay does in your car. Pretty sweet. -Screen is excellent, great definition. I'll post more after a ride. -I hooked it up to the GPS power source Ducati provided but hid behind the bodywork, just as I had for the Zumo. I left a 2 amp fuse in the line just in case, probably overkill since it's fused anyway. I spent most of my install time just getting the wiring how I wanted, making sure the wires didn't foul movement at full lock, or get rubbed by any other part. -It paired w my phone in maybe 10 seconds. Paired and works seamlessly. -I'm not really a listen-to-music-while-riding guy, but maybe I'll install the Scala unit from my old Arai. We'll see. Hey, can't beat it for the price, 10% of the cost of my Zumo, not adjusted for inflation.3 points

-

If you only had a little more height... What about going 2x3 high (3x2?) on one side to leave the full wall open on the other side?3 points

-

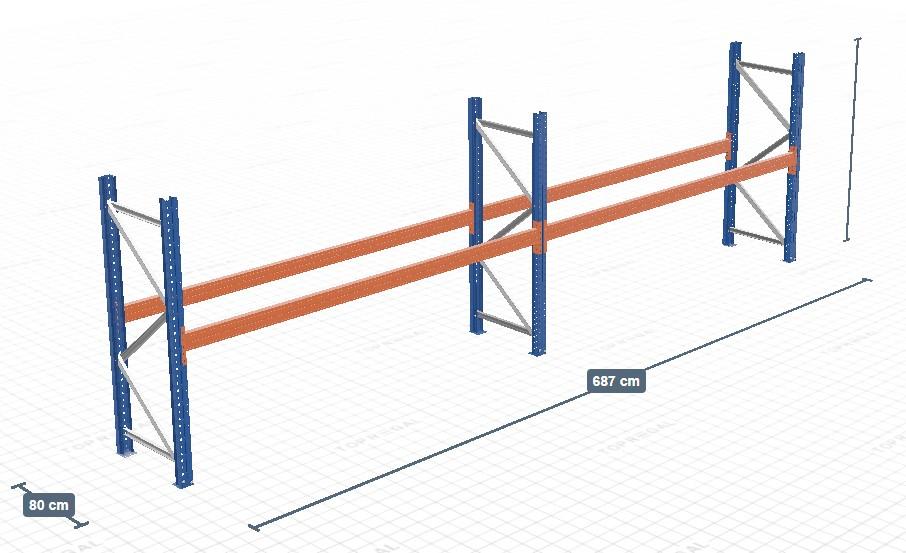

'No' is not really what I wanted to hear, but reading on it sounds more like a 'maybe' to me! One option I have considered (but hoped to avoid) was to convert the cantilevered shelves into a 4-post rack. Unistrut is also available in deeper channels (61mm and 81mm), but that gets expensive real quick. 'Back-to-back' 41mm channels are also available. But using any of them for the verticals forces the workbenches away from the wall--and I don't know if just using those struts would solve the 'moment' issue in any case. A 4-post rack may be the least-worst solution. I'd still have to work out the number of posts-per-bike, but that should be a fairly straightforward load (4x) calculation--and that could still allow me to position large equipment underneath (such as a lathe) if it were located "between bikes", so to speak. * * * Okay, so I've now looked at commercial pallet racks and I think that may actually be the way to go. They are available here in a number of configurations, but most critically in 800mm deep versions with spans up to 3.6m! I have 7m of wall, so I could fit a six-post pallet rack with two 3.3m spans, each of which is designed to support 1,100kg. A fully laden VFR800 (the largest bike I would be racking) weighs less than 300kg, so I could store three of them with no issue--and only have one vertical post "in the way" down below. Something like this, but with the horizontal carriers moved all the way to the top. (I've read that the loading and stability of "one-level" pallet racks are much reduced, so I'd have to brace it to the walls, at least.) I'd also have to think about the shelf covering (if any)... Thanks for your insight--critical comments are in many ways more valuable than encouraging ones! Ciao, JZH3 points

-

I'm enjoying this thread, looking forward to all the other things you will figure out, and the final result. Are the elevated motorcycle "shelves" really just for display, or do you intend to walk downstairs one morning, decide which bike is perfect for a ride that day, bring it down and zoom off?3 points

-

Couple things: "All fuses are good" Does that include the Main Fuse that is under a cover on the solenoid holder? I have to ask. Also, solenoids come in two styles and they are mirror images of each other. There is usually a "B" (Battery) and an "M" (Motor) molded into the plastic near the cable posts. If you got an opposite (and your original unit was really bad), you will need to re-pin the wires on the plug in the mirror image too. Also closely inspect the wires going into that plug. It is VERY common for those to be melted and burnt and can cause what you describe. Sometimes you don;t realize how bad it is until you really look close. Also, you can plug in your original solenoid just to see if you get any power again. Great choice in a VFR model and good luck.3 points

-

The only thing that sticks clutch plates together is cold oil and viscosity. My bikes never suffer from that, probably because they never sits still long enough. The clutch has an inner and an outer, where the fibre discs engage with the outer, driven from the crankshaft, and the steel discs engage with the inner and drive the gearbox input. When the engine is in neutral, the clutch spins as one unit, but when you drop into 1st gear with the clutch lever pulled, the inner will quickly stop and the outer carries on spinning, which is why there is often a bit of a clonk. I'd suggest letting the engine get up to a good operating temperature as that will give the clutch a chance to be bathed in nice hot oil. At that point I would shut off the engine and put the bike in gear with the clutch pulled, and then try rocking the bike back and forth to free up the sticky plates. If you need to get to it, clutch disassembly is no big deal but you will need a spare gasket and the patience to scrape off the old one without galling the mating surface. You can do it without dropping the oil, on the sidestand. Just don't drop foreign objects into the open sump...I just swing the case to the side and hang it up so I don't need to do anything with the ignition pulser wires. My 6th gen is below but the 5th is basically identical. Remove the 5 bolts and the clutch can be easily pulled apart, but use a torque wrench and go softly when rebuilding it.2 points

-

Hey y’all, I recently picked up a 2005 VFR800 with 40k miles. It has some wiring issues and I don’t have the time to sort it out myself. Anyone know of any good techs in Houston we can trust? Quick notes: I just ordered the front wiring harness recall from Honda and they will replace it for free in a few weeks. I’m assuming I’m still going to have issues after that so I’d like to line someone up now, if possible. My dealer already said due to the age all they can do is the recall, nothing else. Previous owner recently installed the VFRness, new R/R and Stator. Thanks in advance!2 points

-

Is your reg/rec flat on top of the fins, or curved? The original OEM ones were flat--as in pancake, like your battery will be if you rely on one! But, Honda upgraded its reg/recs at some point to the curved, or rounded fin version. I don't think they are MOSFET, but they may be less prone to failure than the original OEM reg/recs. Maybe you don't have a reason to panic! (FYI, I believe the SH847 Series-type reg/rec was OEM on Suzuki DL1000 Stroms). Ciao, JZH2 points

-

Well I must say luck was on my side No fuel pooring today, fuel has swollen the O-rings so no leak anymore, great! The oil leak at clutch cover was gasket that had slipped off So just to relocate as tight back. Then the fairings was mounted, you gotta love new bolt's for them Then only one thing left, switch the rear wheel between my RC24's after the plastic was on Then to get a insurance as take it in road use and ride to petrol station for fuel as check air pressure (forgot that at home) And then to nice road's As a nice cafe Really enjoy the bike, some things to sort like fork over damped and front brake feel not the best but otherwise running like a champ! Some pictures from ride home from Cafe Really love this motorcycle2 points

-

I found this video which describes the right hand switch disassembly and cleaning which could be needed if you have poor headlight connection. https://youtu.be/3_QMOKXJJmc?feature=shared I followed the video to be able to check the right switch assy. Some things weren't mentioned in the video: - to remove the switch assy from the bar i had to remove the brake lever. - i takes a large force to release the clipping feature that holds the right side light button on the switch body. You can see the why on the pic, snap feature is really stiff. Disassembly of the left side switch: Dimmer switch is just snapped in place and wasn't hard to get out after removing the cable strain relief and a fixation screw. you can see the soldering location for the blue/white feed wire which was broken off on my bike on below pic. This is what the left switch assy looked like before removing the dimmer switch: - i disassembled the passing button also to be able to remove the switch cover and gain better access for soldering. I struggled a bit during the removal so I am worried about getting it back together. Note: there's a spring and ball on the passing button for the tactile feel, this wants to escape and will be next to impossible to find if dropped. (Visible in lower right on pic)2 points

-

It looks like there are good resources for "Beam Loads" and "Column Loads" for Unistrut at given spans online. The only worry I would have is it pulling out of the wall, or bending just below the 45 degree brace. If they are much taller than the bikes, you can run a piece of Unistrut or metal/wood beams across form side to side to prevent collapsing in on itself, and use those to hang your lighting. Although you are extremely thorough in everything I have ever seen you do, so you probably already have a way better plan than my quick brainstorm... Do post pics as you're building it, we need a good project here to keep us dreaming about our own work spaces! Is it too wet there for painted or epoxy floors?2 points

-

2 points

-

This guy should be able to sort you out, he’s had everything I wanted for my 89 https://shop.xtremedecals.com/shop/category.aspx/vfr-series/38/2 points

-

As Stray points out, having a structural member in your garages ceiling has some benefits as far as options for lifting or stabilizing the bike I have a 1 ton chain hoist mounted above my lift. They are about $70 at HF. First pic I used my hoist to lift the bikes rear up as bit to do some work this Spring. Second pic I used the hoist to stabilize the bike at the handlebars as I was going hammers and tongs working on it this past Fall. Good tip over insurance without having to strap the bike down.2 points

-

2 points

-

I got Hepco and Becker. Can be done with or without top rack. I chose without. The racks, after initial installation, can be removed or installed in about 5 minutes or less.1 point

-

1 point

-

Tank looks great, both brake and clutch systems flushed less than 50 miles ago but was June 2024. Coolant was also flushed and changed at the same time. @mello dude I'll try to take some pics today, all I have taken are at night in the garage with shadows and such...because I need to finish wiring the garage and hanging the rest of the lights. (It's miserably hot on a ladder in there lately!)1 point

-

If you anchor the feet of the racks, and anchor to the wall, you should be fine with an extra beam on the wall side lower down. Another general principle is to not exceed beam deflection by (beam length)/180".1 point

-

+1. I kinda take Keny's posts for granted, but he is always buying, selling, riding, and improving bikes. Fun stuff.1 point

-

Great advice by the dude, BLS and gaz. Do not just start a bike up in the middle of winter storage, twist the throttle a few times, and turn it off for another month, for the reasons described above. And even if you get that rare winter day and take it out for a quick spin, a five or 10 minute ride will not help, even if the temp gauge settles in to normal operating temperature. As mentioned, you need at least 20-30 minutes until the cases are too hot to touch in order to burn off/evaporate all that bad moisture in the crankcase. Sticking clutch plates are above my pay grade however, plenty of experts here on VFRD to help. Cheers.1 point

-

1 point

-

1 point

-

Hi, i just bought a -97 VFR750F, originally imported to Sweden from Germany. I got 4 circuit schemes with the bike so i had to figure out the correct one. The bike variant is VFR750FV - so the 'G' for Germany electrical scheme is valid. This means that there's only one light relay and no headlight circuit breaking on the start button on this bike. The problem with the bike is that headlight won't come on but passing button works so light relay and ground is probably OK. I checked wiring with the circuit scheme and a multimeter, started on the right switch assy since this is a known issue but all was good there. Then i opened the left switch assy and voila! The blue/white wire feeding the dimmer button switch has broken off. Seems to be a soldering hack job by one of the previous owners. I tried to see where it's supposed to be but it's cramped in there, hard to get access and solder it properly so i'll have to disassemble it.1 point

-

It shouldn't take too much time to take a bike "off the shelf", but I don't know if I will ever have the luxury of choice like that. I was thinking more about being able to take one down, prep and maybe do some work on it--as well as ride it for a while--before moving on to another one. Ciao, JZH1 point

-

I sent SW files and prints the other day. I use SolidWorks Maker at home, and Professional at work. The Maker version is only 49 bucks a year, and totally worth it, being an industrial standard. I make all of my 3D printed or machined parts at home using SW.1 point

-

1 point

-

As an engineer. No. Just....no. Do not put that much moment on your walls. They're not designed for that. Unistrut isn't really meant for doing what you want to do. That angle bracket especially. Its great for easy adjustments and quick builds. Not to hold motorcycles. Figure out how you want to 'tray' the bikes. Make suitable 4 post rack. Use unistrut if you want, but use pallet rack would be easier. Can still anchor it to the wall for safety. Figure your real loading is more like 4x. 2x is considered 'sudden loading' for objects already in contact with each other.1 point

-

Pretty good memory mate! First one I saw on EBay was a FH027AA for a 2021, the next one was a FH020AA for the 2013/17. Thank You.1 point

-

What a fun project. From an engineering perspective, the closer you sit the bike to the vertical supports, the lower the bending moment on the cantilever will be. I do occasionally drive a counterbalance fork lift (I have a licence and everything!) and I can tell you that putting 1 tonne loads onto the third level of pallet racking takes some hand-eye coordination and a little nerve. You shouldn't have too many problems with your nifty lift truck as I expect the visibility will be much better. You will need to make sure the floor under your shelves is really smooth as the wheels look quite small.1 point

-

And yet another lot done ! From now on, it might get a little slower (yup, even slower than now 🙄) as I just moved out and don't have a space on my own to work from, I'll have to do whatever I need at work during breaks. Also, before I put her back together, I've got to spend about 1k in parts and quite a few hours, the lady needs a lot of attention ... The most worrying is that constant oil sweating at the top of the engine, I've moved the bike to a storage unit 3 days ago and noticed today that it keeps leaking a bit under even though the engine has been on for over 6 months.1 point

-

1 point

-

So it's getting there, radiator on, fuel tank on Got new fuel filter as fuel lines between tank and pump Did just paint the upper thermostat housing that you mostly see, it was time for new bolt's as well Tomorrow I should get the new plug for the clutch cover, so could basically then fire up the bike as battery is charged. Need to get some fuel. If all goes well and it runs and no fuel pooring of carbs it needs fairings on still, and there is a thing to fix on upper fairing before mounting it So my plan to have it out during my 2 vacation weeks is getting a bit tight, but perhaps possible 🤞1 point

-

Yeah, that's kinda what I'm driving at. Most screens that are cut like that, the top "plane" tends to match the angle of the top of the tank. Cheers!1 point

-

It's this view that cements it for me. The shape of the relief/flare for the handlebars at full lock just flows better with the other bodywork pieces and tank. A little more organic looking. When final placement is done, trim the screen down a bit to compensate for the height proportions and you can even re-angle the top cut to (more) match the angle of the top of the tank. (If that makes sense)1 point

-

1 point

-

It's a new project. But I'm determined. 99 vfr800. Bought it as a project and am tearing into it... bodies aren't terrible, needs a few misc parts... I'll check mileage when I plop a battery back in. As for pictures, I'm tryin to get those figured out1 point

-

Oh what joy. Brake fluid flush time again. Good job I decided to pull the secondary master cyl to inspect/ clean the little green plastic return valve assembly, piston seals had let go & were weeping Dot 4 up the bore, rusty Schmoo had collected under the boot too. Poor design imho, no wonder Honda junked the idea a few yrs later. Anyhoo. Several lolly sticks / lint free cloth & a litre of brake cleaner later, she's nice n clean again, I also honed the piston bore, this shifted the brown rust deposits, I used a grey scotchbrite wrapped around my thread tap handle, approx M8 diameter, which proved a very effective way to get a good fine cross hatch hone in the piston bore, new Tourmax repair kit on order. I'm still amazed with the micro tech that's gone into the return valve. Wonder if anyone's drilled the return bigger, if so, any benefit or detriment to the braking?1 point

-

Last Sept. I finally got my new to me 5th Gen in running order. Unable to find any hard bags for it I ended up building a pair if saddle bag supports for my soft bags. I used 5/16" - 8mm weldable rod for most of it, with some 1/4" - 6mm for the forward stays. Everything was cold bent on my 6" vise with a 3lb ball peen, then welded. They are easily removable with 4 fastenings per side. I used them on a 3,000 mile trip that Fall and worked well. I did think though that a six pack rack would be helpful. Not finding anything available for the 5th Gen, and having trips to VA, TN, NC, then 4 days after that up to New Brunswick and the Cabot Trail in Nova Scotia in May, I figured I'd have a go at making a serviceable six pack rack a shot. Again I used 5/16" - 8mm rod for the frame and some 5/8' - 16mm X 1mm flat for the slats. I piggybacked off the Saddlebag supports to make it easier to mount, and threaded the rod at the forward end to adjust the rack, but also make it removable. The cable clamps on the aft lower are for the same reason. I can remove the rack in less than 2 minutes, but it is strong enough that a buddy and I lifted the back of the bike off the ground with it. 2 trips and just under 5,000 miles this May, and it has indeed proved useful. I'm a form follows function guy, so I'm not bothered if its less than elegant. Besides, there's so little in the way of luggage options for the 5th Gen that I had to figure out something if I wanted to go touring The last pic was taken around the 20th of May at Rouses Point NY as I was returning from NC etc. I generally will go up to the Quebec Border and turn right to get back home. This eliminates going through CT and MA, a far more relaxing way to enter Maine.1 point

-

Hey everyone, I’m new here and recently picked up a 2005 Red VFR800. I’m located in Houston and would love to meet some folks in my area. Currently the bike is not running, I believe it’s a wiring issue so I’m in the middle of troubleshooting and plan to make a new post or two for help. I also have a 2011 HD Street Glide and 2014 Yamaha Stryker. I used to have a 2006 CBR1000rr and always wanted a VFR. Looking forward to connecting with a few of you soon.1 point

-

1 point

-

Good morning everyone, Here are the progress and set backs from this week and last weekend. A lot of masking, painting, bleeding, re-masking, airbrushing, repeat. If anything, that job is teaching me patience and accepting my mistakes. Still unsure about what happened about on the "RC36" on the right hand side on the seat cover. Most likely a mix of airbrushing too thick, too soft sanding (p1200) and possibly a bad vinyl ? But once again, that will be adjusted on the next step. Slow and steady wins the race ! 🐢💪1 point

-

Cool Idea! I'm personally not sold on steering dampeners just yet, but more power to ya! If you figure this out it would be valuable to the forums for sure!1 point

-

Version v3

11,905 downloads

As originally made available by HispanicSlammer, this manual first came out for the 2002 model (first 6th generation model year). Not much has changed with respect to servicing the 6th gen VTEC since it was introduced in 2002. By-and-large, this manual applies to all 6th generation VFRs for years 2002 to 2011. There are only minor differences in some later years, most notably starting in 2006, with changes to VTEC engagement RPM and the wiring harness. All the hard work for this scanned version was done by an unknown source. The actual manual part is not searchable since it is a compilation of page scans only. I was tired of scrolling around the huge document trying to find what I needed. So I spent a few hours generating bookmarks. This version has bookmarks for all the subsections for each major section in the manual. The first page for each major section lists all the subsections and these each now have a bookmark for quick and easy document navigation. If you enable bookmark searching in your PDF reader - and most PDF readers support this - you can then search for major terms and subsections and get search results in the bookmarks. Remember, this Factory Service Manual is far from perfect. Firstly, it presumes you have a reasonable level of mechanic/shop experience. Secondly, it contains many errors. Not just typos, but erroneous information. Some of it was fixed in errata releases in subsequent years but not all of it (trust me, I've checked). I strongly advise that you search for relevant topics, review them and post any questions you may have in this most excellent of forums, VFRD, prior to performing your own major servicing of your VFR. There are amazingly helpful members here and a lot of great How-To posts. Enjoy and be safe! P.S. new version v3 has fully searchable text thanks to Adobe Acrobat's amazing "recognize text" OCR feature which has the added bonus of deskewing the page images as well as generating fully searchable text!1 point -

With this Abba stand you will be able to not only lift both wheels of the ground but also remove the whole front end for instance when you need to replace head bearings.1 point

-

Version 1.0

105,292 downloads

This is the same manual that is already available here on VFRD. I have been using this so much lately that I went ahead and made it a little more useful for myself. I assumed that some other members might like to have it as well. Combined both files into one. Optimized the file size so that it is only 60 MB. Ran OCR text recognition to enable text searches on the entire book. Rotated pages that had landscape page diagram for ease of viewing. Created bookmarks for each chapter & sub-chapters. I figured this was the least I could do to contribute since I am getting so much help from this forum.1 point -

As another that owns both, my $.02 is that it's maybe more a question of "what are your preferences and priorities" vs "is one better than the other"? You have to weigh the differences between them based on what's most important to you. The main absolute differences are that if you want factory luggage and / or ABS, you'll need a 6th gen which can be a real value for a bike that you can pick up for about $4,000. If you want the GDC's, you have to go 5th. I can ride either just as readily and have ridden both long distances. Past that things become more subjective depending upon intended use and personal preferences and abilities. I like that my '99 does not have a wax unit to cause trouble, a cat or cam chain tensioners that can fail. In an ideal world I'd take the two and meld them together keeping what I like best about both. Several years ago there was a post from someone, I think in Ohio that did essentially that. Actually in my ideal world Honda would still be producing the 5th gen - ah well. As I think of the two, while I like my 6th gen and will probably sell it as the miles pile up, I love my 5th gen and do not intend to ever part with it. I plan to leave it on the center stand in my garage and let it remind me of all the fun rides I had on it. YMMV.1 point

-

1 point

.jpg.ce681c66c3d4a2a7aac284f44fda764c.jpg)