-

Posts

515 -

Joined

-

Last visited

-

Days Won

3

Content Type

Forums

Profiles

Gallery

Blogs

Downloads

Events

Everything posted by zupatun

-

these rotors aren't "warped" so to speak...the carriers are about 4mm thick stamped aluminum...and I've seen people hit curbing with them and bend hte carriers...whether they are "fragile" or not the carriers are pretty standard for japanese bikes and most people just plop down money as they have no way/idea on how to fix the issue. I've had these on the bike for 9 years and I got them REALLY bent second hand. BUT they had more meat on them than the stockers which had 76k miles on them. So, I swapped, bent and got them back into true. I probably bent tthem trying to break the bead (I do my own tires)...when the rim slipped a little on my bead-breaker--applying about a shit-ton of my weight on a lever trying to break the bead...a not so gentle treatment of the rotor/tire carrier. IF I look at the run-out--the data shows it to be out of plane--I'm just bring the disk all into alighment with the rotatioary plane of hte wheel.

-

Right hand side as-is: and with gentle persuasion:

-

Left side as-is: and with Persuasion:

-

Left rotor had about 7mils runout (0.007") and Right had about 6 mils runout. Afterward the Left is at +/-1mil runout and the Right around max 1.5mils runout. I'll ride this morning to check if the shudder I was experiencing braking is improved or not. IF NOT I'll be checking he head bearings and make sure the nut is torques correctly...if the shudder is gone I'll know I most likely bunged the rotors last couple times I changed tires. Matt

-

I must have tweaked my carrier putting a tire on last year. I keep noticing it under hard braking...so it must not be too much. Putting the dial indicator on a stand and checking runout as I type. I'll post some numbers shortly.

-

-

The bike, originally, was intermittently not starting. Then, after one instance, the bike shut down mid corner (same day). 1. I checked starter solenoid, fuel cut solenoid, per the manual with my DM--apply 12V across two contacts--get beep across the others with my DMM (set in diode check)manual says I should see continuity and I do. 2. fuses (FI, bank angle, lights, fan, main et al). 3. Fuel tank/fuel pump plug had voltage to it and stopped when fuel cut switch fires. 4. No spark at spark plugs but I have 12VDC at all the coils. 5. Turn on bike, NO fuel pump cycling, neutral light and FI light on. after a few seconds Fuel cut relay starts clicking twice a second or so, hit starter , no joy. 6. IF I unplug the Fuel pump, neutral light on, FI light lights for a few sec and turns off (hear fuel cut relay click), hit starter, no joy. 7. checked bank angle sensor (checks OK). 8. Friend sent me a fuel pump assy...put it in and No joy, same as usual. Friend, Mapmaster, says to check all my ground leads (starting with Fuel Pump and cycling with Fuel cut soleniod, Engine stop solenoid and bank angle sensor for intermittent ground or high resistance (higher than an ohm or two). 9. I decide to pull the solenoids and re-check the grounds (look good low ohms) and decide to re-test them with power to the solenoids (not just the grounds). put 12V across a spare solenoid and closed contact resistance is 0.6ohm. Pull Fuel Cut Relay, apply 12V to fuel cut relay solenoid and measure contacts 0.5ohm. Pull Engine Stop Relay, apply 12V to relay, measure across contacts -- 10 ohms! it's ONLY 10 ohms...a pittance of resistance in the ignition/run circuit... 10. Swap out known good relay (0.5ohm) for suspect Engine Stop relay...turn on ignition, neutral light, fuel pump cycles, shuts off, hit starter, bike starts! 11. THROW BAD RELAY in TRASH. Shut bike off, start again! The manual does NOT say to measure the ohms of the relay--JUST look for "continuity"...so thanks MapMaster for asking me to look at ground for high resistance...or I wouldn't have thought of looking at the resistance of the close poles on the relays!

-

Checked codes even no FI came on. Started yesterday...started intermittent...try 2 times, shut off, fired up the third. Rode it a mile or two, came home shut off, restarted, shut off, no joy. Let it sit, no joy, turned off, started up. Rode it another mile...quit in a turn one mile from driveway. Pulled over, no joy, let sit 5 min...starts up. Ride home, park, now it won't start at all...tried 5 times charged battery, tried again, no joy. Turn on bike and I hear the fuel cut relay (under right rear cowl) clicking on and off... (THIS JUST IN!!!) Fuel pump is not cycling! Matt Rot

-

I have large hands. Not a huge, but not a small person either (6'1"). I reach in, and replace by feel...dont remove anything to get access. Matt

-

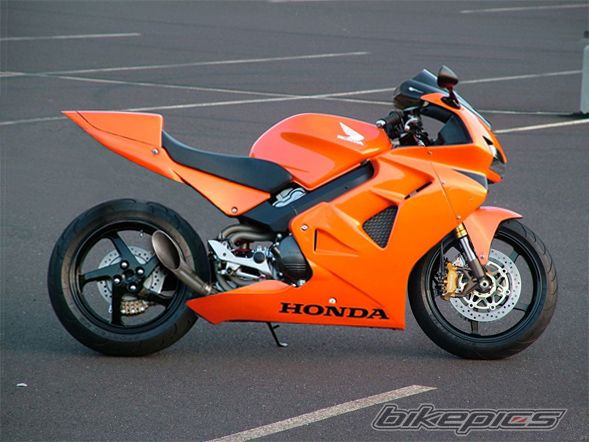

Looks like a trackday bike to me! Sweet buy! Just a little jealous.

-

I've had Fox (4th gen) and Penske and Ohlins on my 5th gens. ZX-10 on my old SV650 and I've got a Nitron double clicker on my XSR700. Properly sprung is the most important aspect of the shock. Any shock will lose performance over time, but a shock (and forks) not sprung correctly will not work well for most situations other than sedate, single riding. Penske is wonderful, graceful degradation. Ohlins is very responsive to comp, rebel changes and works till all of a sudden it doesn't and needs a rebuild (pogo stick over 4 months of riding after 11k mi). You get what you pay for! Matt

-

Hi zupatun, Thank you for your donation of 15.00 USD. We look forward to improving the forums with your donation. Thanks VFRDiscussion

-

You can get connectors from roadstercycle.com Easy peasy...

-

Motorcycle hearing protection/earplugs

zupatun replied to LPadilla34's topic in Clothing & Wearables

I have made my own custom fit earplugs, and they work OK, but in my new helmet the depth of the speaker slots is shallow and they get shoved into my head...my ear canals actually bleed...which sucks. So I've switched back to foam. Also my left ear canal is much narrower than the right... I've used these from Surefire in the past. They are relatively shallow, but do an OK job of sound attenuation. The nice thing is they don't sit too deep into the ear canal and the outer ring holds them in place. Not sure they will pull out or stay in putting a helmet on, but I don't think they are super expensive to try. https://www.surefire.com/ep3-sonic-defenders.html ou can see they have different sizes...I would order a Large and a Medium set and mix and match to get my left ear fit better.- 37 replies

-

- ruptured eardrum

- hyperacusis

-

(and 3 more)

Tagged with:

-

I paid $2800 for my VFR with Ohlins rear shock, with 76,000 miles on the ODO. Cosmetically, the bike had bodywork repairs and repainted at least once, maybe twice. I didn't think twice about it...and picked it up in Portland and rode it home to Virginia over the next 4 and a half days. Now the bike has 98,000+ miles on it and runs like a top, but I've dinged it up going down in Turn 1 at Summit Point raceway so I had a SebSpeed clutch cover put on it. IF you can talk the guy down to at least 3K...you have a great bike for a great price. The $35K bike at half the asking price of the garage queen is a Good Deal IMO.

-

No Frankenfork for me. I used 6th gen triples, F4i forks, fender and calipers with my 5th gen wheel. Matt in Haymarket.

-

F4 and F4i forks are not the same. F4i forks total length are shorter than VFR forks. Also, the brakes from your VFR and fender wont work either. The F4 ('99-'00) forks are indeed 795 mm in length to the VFR's 800 mm (funny that). The F4i forks are 785 mm. The end result is that the fork tubes sit about 10 mm below the handlebar top edge, but more than enough for the bolt to clamp, the handlebar-to-fork mount being 33 mm in height. VFRworld threads are where I started my research: https://vfrworld.com/threads/vf4ir-the-project-begins.20085/ And https://vfrworld.com/threads/vfr800-5th-generation-a-gearhead’s-delinking-brake-saga-and-the-interceptor-ss.3617/ Matt in Haymarket

-

I remember the tab/bodywork nightmare that was my 4th gen...but it was a lovely bike til someone hit me... Your work looks exemplary! Matt in Haymarket.

-

If you're going from Montana through Colorado, you might swing North and go through Medicine Bow-Routt National Forest...riding AND vistas 130 and 101...it's on my bucket list and it's Just North of Denver Colorado etc...so not too far out of your way... Matt in Haymarket, VA

-

It doesn't bubble. It will soften and you can bend it. It is hard to get it evenly to higher temps because its thermal conductivity is low. Good thing about that is you can heat (sort of) select areas with a temp controlled hot air gun to move it into position. I've done this...but it takes a while for a large area to cool into shape. However cooling can be hastened with a damp shop rag or squirt bottle/misting with water to set or fix the shape. Gloves may be needed...but will leave an imprint in anything soft. Matt in Haymarket

-

I use the clear 3M protective film to protect the tank from my tank bag and zippers...not sure if that's the reason you're asking but that's what I do.

-

Plasti-fix, Plasti-Aid, Plasti-Weld all give you the option of making or repairing parts, but can require some skill at fashioning/forming missing parts... https://goldwingdocs.com/forum/viewtopic.php?t=22655 I've used ABS glue to fill/glue thin cracks and it works well. I've used ABS glue to weld on a backing/reinforcement of ABS onto a part to strengthen it. I've also used ground up ABS with ABS glue to do the same. The most successful and simple method I've used is employing a temperature controlled soldering iron to melt ABS to repair cracks, along with ground up ABS and larger ABS parts to fix, fill and reinforce ABS. The welding of ABS with a soldering iron is probably one of the best ways, because you're keeping the material properties essentially the same, not relying on a chemical bond between two different materials. ABS does not easily crystallize, unlike other polymers, with applicaiton of heat and welding. As long as the temperature is not too hot, it will weld and regain most of it's strength and resiliency. Just my two cents. There are plenty of ABS welding "How To" videos on YouTube if you want to decide if that's a rout you might need. It is difficult to replace parts with ABS welding. That's better done IMO with the above products. BUT repairing cracked or broken pieces and quickly reinforcing them, Welding with a soldering iron is fast, effective and cheap. Matt in Haymarket

-

most excellent. Can't wait! Matt in Haymarket

-

I've had similar codes and issues. When these wires become loose in the gang block (Orange in my 2000) a reading from the sensor circuit associated with any loose green ground wire can result in a positive floating voltage giving this generating an errant signal and the ECU flags that as a reading and resulting error code. Matt