-

Posts

4,263 -

Joined

-

Last visited

-

Days Won

67

JZH last won the day on July 6

JZH had the most liked content!

About JZH

- Birthday 01/01/1965

Contact Methods

-

Website URL

http://www.vsource.org

-

ICQ

0

Profile Information

-

Location

Leiden, NL/London, UK

-

In My Garage:

6 VFRs, an RVF, an ST, 2 CBRs, an RS and an SXV

Recent Profile Visitors

28,178 profile views

JZH's Achievements

-

Had to look that one up! Measuring is good: I have loads more to do. I also have to re-design the carrier (again), because I forgot about my SXV550... First world problems! Unfortunately, it is longer and taller than the other bikes, which throws off some of my calculations. Better to know now than later... Ciao, JZH

-

That video is pretty much exactly how I did mine last year. Easy peasy, provided you're prepared to rebuild the caliper (and don't mind one-way mods). The only other caveat is that this requires a 14mm rear master cylinder to achieve a comparable hydraulic ratio. Ciao, JZH

-

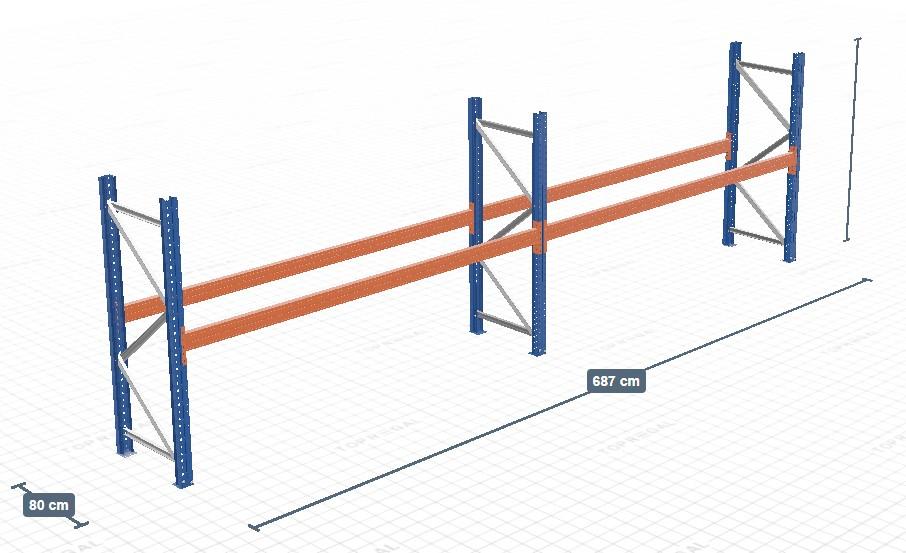

Nice "shed"... It's about twice the size of mine, but I saw some good ideas I think I might borrow! Regarding the racking, I think I will be able to use the lower beams on the back sides, as Yoshi suggested, as well as bolting the feet to the floor and bolting the tops of the frames to the walls. That should be that. As for what goes onto the racks, I think I've got a solution: I went through a couple of designs, trying to minimise the expense of the materials as well as the cutting and welding operations I will need to do. There's still a lot of steps to manufacture one of these, and I still have to do it 6-7 times... The wheel chock parts (not drawn, because I'm not making them) come from this kind of Baxley knock-off: In laying out my motorbike carriers, since I have 6-7 of these wheel chocks already, I've measured and duplicated the locations where the M10 and M12 bolts go. My bikes' wheelbases range from 1,440mm (the 5th gens) to 1,335mm (the NC35), and all the bikes' rear tyres sit basically in the middle of the steel plate at the back. It's pretty secure, but I will probably also strap each bike wheel to the front vertical to make sure it can't go anywhere. I was also thinking about welding some steel angle onto the plate at the rear, maybe 160mm apart, to help locate the rear tyres, but my bikes all have different sizes of tires, so one size won't fit all (in the same way). Not sure it is necessary, anyway. The fork hoops look huge, but the forks on the pallet stacker are quite large (ca. 170x70), and I don't really want a tight fit. I haven't actually measured the clearance between the bikes' bellypans/stands/exhausts and the forks that need to stick through, which I will do before I finalise this design. I decided to use the 60x60 c-channel, rather than the angle iron I had first used, mainly because of strength. I will have to plasma cut them, but I can set up a jig to make that do-able. This way, the channel just sits on top of the 50mm horizontal beams of the racks, and it will be very obvious when it has dropped into place. I've provided for the fitting of 100kg casters, which should make these carriers more useful when down on the ground. I wonder if I can make some sort of (removable) lifting device using the swing arm pivots, a la an ABBA Stand? That would make them even more useful for chain adjustment, etc. And I'd only need to make one, which I could pop into each carrier only when needed. Any thoughts on my bike carrier frame design? Cheers, JZH

-

Is your reg/rec flat on top of the fins, or curved? The original OEM ones were flat--as in pancake, like your battery will be if you rely on one! But, Honda upgraded its reg/recs at some point to the curved, or rounded fin version. I don't think they are MOSFET, but they may be less prone to failure than the original OEM reg/recs. Maybe you don't have a reason to panic! (FYI, I believe the SH847 Series-type reg/rec was OEM on Suzuki DL1000 Stroms). Ciao, JZH

-

Hi Lars, yes the Euro-spec bikes from that era had headlight on-off switches and 'passing' switches, whereas the US-spec bikes did not. I have fitted Euro-spec switch pods to US-spec bikes in the past, however, so they are not that different--but you do need to be looking at the right wiring diagram (which you are)! Thanks for the great write-up of your repair, and for high-quality photo of the wiring diagram, too. I'm sure that will be useful to someone in the future. Ciao, JZH

-

'No' is not really what I wanted to hear, but reading on it sounds more like a 'maybe' to me! One option I have considered (but hoped to avoid) was to convert the cantilevered shelves into a 4-post rack. Unistrut is also available in deeper channels (61mm and 81mm), but that gets expensive real quick. 'Back-to-back' 41mm channels are also available. But using any of them for the verticals forces the workbenches away from the wall--and I don't know if just using those struts would solve the 'moment' issue in any case. A 4-post rack may be the least-worst solution. I'd still have to work out the number of posts-per-bike, but that should be a fairly straightforward load (4x) calculation--and that could still allow me to position large equipment underneath (such as a lathe) if it were located "between bikes", so to speak. * * * Okay, so I've now looked at commercial pallet racks and I think that may actually be the way to go. They are available here in a number of configurations, but most critically in 800mm deep versions with spans up to 3.6m! I have 7m of wall, so I could fit a six-post pallet rack with two 3.3m spans, each of which is designed to support 1,100kg. A fully laden VFR800 (the largest bike I would be racking) weighs less than 300kg, so I could store three of them with no issue--and only have one vertical post "in the way" down below. Something like this, but with the horizontal carriers moved all the way to the top. (I've read that the loading and stability of "one-level" pallet racks are much reduced, so I'd have to brace it to the walls, at least.) I'd also have to think about the shelf covering (if any)... Thanks for your insight--critical comments are in many ways more valuable than encouraging ones! Ciao, JZH

-

Let's hope it stays a "fun" project! Floor smoothness requirement noted--thanks. Ciao, JZH

-

It shouldn't take too much time to take a bike "off the shelf", but I don't know if I will ever have the luxury of choice like that. I was thinking more about being able to take one down, prep and maybe do some work on it--as well as ride it for a while--before moving on to another one. Ciao, JZH

-

I've been thinking about the same thing: running horizontal struts side to side along the house's wooden beams in addition to anchoring the verticals into them at the top. That's a 4.3m span... But, it also could be a great way to suspend lighting, air lines, etc. (I'm not sure what kind of floors I have at this point. There's actually wood flooring in there now. Not sure what's under it--more wood? That's not a great for a garage!) Given my space limitations and bike collection, I kinda have to do this, but how it will be done remains an open question. I will definitely photograph my progress/downfall as I go! Cheers, JZH

-

Generally, Honda parts like that are bike-specific. That part number includes "MCW", which is the Parts Classification Number for the 6th gen VFR (VTEC), indicating that Honda originally designed that part to fit that bike. It is possible that they then spec'd the same part for other bikes (if so, the part number would not change), but unlikely. Ciao, JZH

-

Okay, I see what you mean now. Yes, I plan to make some sort of "sled" to allow the bikes to be lifted up using a fork. The frames don't need to be very heavy duty (i.e., heavy), but I do need at least six of them, so I'm pretty sure I'll be welding them myself. Because the shelves will not go all the way to the wall (because the verticals will be in the way), I was thinking about having each sled extend over the front and rear of the shelf with a kind of 30-40mm "tongue" to keep the sled effectively locked in place until lifted straight up with the fork (lift). Fortunately, I have something like 6-7 of these Baxley Wheel Chock knock-offs already, which is a wheel chock design I like because it pinches and holds the front wheel very securely: The clever bit of this design is the articulated wheel clamp, which would be fairly difficult for me to duplicate, but I could probably create a lightweight, fork lift-compatible frame which simply includes a horizontal bracket with angled pivots like that, thus allowing me to use the parts from the stands I've already got. Another thing to CAD... My Unistrut parts arrived, so I mocked one up to get the scale into my head. That bracket is 2m above the floor, which is where the top of the shelf would be. Yikes, that's up there! I'm not sure how deep the shelves should be, but the minimum would be 600mm, and maximum probably 1m. IIRC, the 5th gen in the background measures ~770mm bar-end to bar-end, but in theory the shelf could be narrower than that. The workbenches below will be a standard 600mm deep, but 41mm from the wall. They make these pre-welded "cantilever arms" for Unistrut in all kinds of sizes, up to 1m long, and they're silly cheap (like £8 each), so I will probably use them for the main shelf supports. I'd then only have to cut, drill and weld the 45-degree brackets supporting them, using 30mm mild steel box section and 40mm x 8mm flat bar. Another fun fact is that because my ceiling is 3.5m high, I'll have to buy the 6m lengths of strut and cut them down if I don't want to couple two of them (and I don't!). Fortunately, they will still fit in the van--so long as I cut them first. Ciao, JZH

-

Not sure what you mean? However, there is some question about whether I will be able to get my van (and its hitch) into the garage at all at this point...but there is no question that I would NOT have enough room to maneuver it around inside if I did! I will have some Unistrut to play with in a few days, so I will decide what to do after that. This is an electric "pallet stacker", btw: What makes it different than a "forklift" is that it requires support underneath the load, so I will need to be able to slide the front wheels of this thing underneath anything sitting on the floor of my garage below the bike shelves. So that means everything there needs to be on legs or wheels or a platform. No problem with workbenches and tool cabinets, but more of a challenge with machine tools such as my bandsaw, drill press, welding cart, future plasma table, lathe, mill, etc. Fortunately, I like planning; unfortunately, more than doing! Ciao, JZH

-

The last place she probably wants to go is the Netherlands! Ciao, JZH

-

I bought some of that stuff to build an enclosure for my 3D printer (not yet assembled...). Very cute--compared with the brute utility of Unistrut! Generally, however, aluminum anything is a lot more expensive than steel, plus I'd not really know where to start with calculating the loads and sizes required. I've seen unistrut used in countless (sometimes dangerous) situations, so I'm fairly comfortable using it for the shelving structure. I've ordered some test pieces and brackets, so I will have a better idea soon enough. Yeah, I don't think I want to put a pic of my actual house on t'internet, but it looks something like the house on the left: Mine's not red, not directly on a canal, and is a little taller, but it's a traditional house in a traditional row of Dutch houses like this. Most such houses have had their ground floors converted into modern living areas (from whatever they were originally, such as a retail shop or workshop). Ciao, JZH

-

You'll have to change your "In My Garage" blurb... Ciao, JZH