-

Posts

2,432 -

Joined

-

Last visited

-

Days Won

50

BusyLittleShop last won the day on June 25

BusyLittleShop had the most liked content!

About BusyLittleShop

- Birthday 10/09/1948

Contact Methods

-

MSN

netters2@comcast.net

-

Website URL

https://www.youtube.com/user/BusyLittleShop/feed

-

ICQ

0

Profile Information

-

Location

Sacramento California

-

In My Garage:

RC45 RC30, VFRD Peg Lowering Blocks exclusively for VFR. 5th & 6th & 8th Gen, PM for info.

Recent Profile Visitors

26,841 profile views

BusyLittleShop's Achievements

-

Engine temps below 180ºF or 82ºC is an problem... it means that the moisture produced during combustion is not getting hot enough to evaporate out the pipe as steam... instead that moisture will migrate to the oil and produce a milky white contamination... Note normal by products of combustion is water... . Every gallon of gas creates roughly 8 pounds of water vapor... we all have witnessed water escaping out of tail pipes on cold mornings...

-

Leaky Head Gasket Check... You can visual inspect for a leaking head gasket by pulling the spark plugs and peering down each hole... if the top of the piston is black then no leak that cylinder... if the top of the piston is a bright shiny aluminum then leak detected... because a leaky head gasket allows coolant in and that produces steam under the heat of combustion... the net effect is a super clean piston dome and no nasty black...

-

I replaced my PIAA 60/55 watt Xenon gas Super White bulbs that glow in the 4200 Kelvin range with Speed Metal's 25 watt Cree LED H4 with a working high and low beam... At the time Speedmetal LED kits were $69 each at Cycle Gear... Out back the twin tail light bulbs are replaced with dual round circuit boards of LED... a plug and play system sourced at WSB Laguna Seca... RC45 LED Custom Tail Lights... Adapting the LED to center inside the existing housing requires some mild fabrication... Behold LED tail lights... Hit the stop lights and now you're really shinning.. in fact the intensity hurts the eye... Up grading to LED and you're riding so bright you gotta were shades...

-

If you see *continuous* temps higher than 220ºF or below 180ºF then trouble shooting is in order: Continuous engine temps above 220ºF or 104ºC is also a problem and the proper order of items to trouble shoot are: 1)Faulty radiator cap... system should hold 1.1 pressure ratio... 2)Insufficient coolant... 3)Passages blocked in the radiator, hose or water jacket... 4)Air in the system... 5)Thermostat stuck closed... 6)Faulty temp meter or thermo sensor... 7)Faulty fan... 8)Faulty fan switch... Engine temps below 180ºF or 82ºC is an problem... it means that the moisture produced during combustion is not getting hot enough to evaporate out the pipe as steam... instead that moisture will migrate to the oil and produce a milky white contamination... Note normal by products of combustion is water... . Every gallon of gas creates roughly 8 pounds of water vapor... we all have witnessed water escaping out of tail pipes on cold mornings... The sequence of events to trouble shoot are: 1)Faulty temp meter... 2)Thermostat stuck open... 3)Faulty fan switch... (stuck on)

-

I hear a moan like tire noise or a drive chain too tight... check pressure and slack...

-

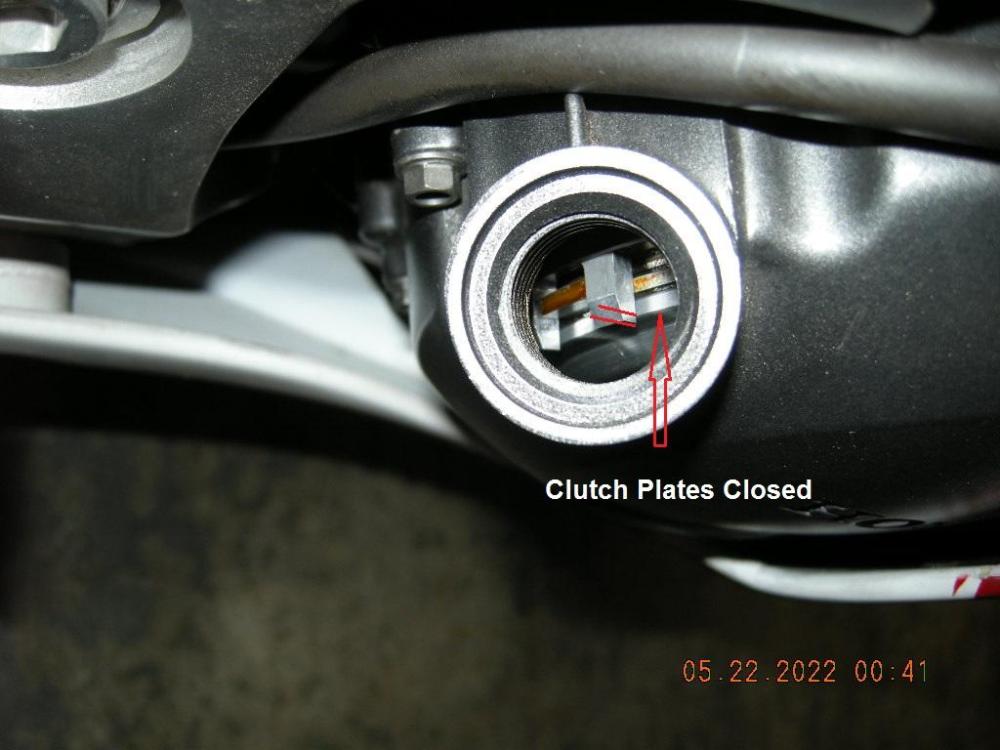

Yes... plates can be cleaned and reused... First inspect the friction plates for glazing... make sure you have plenty of material to work with... your shop manual states clutch thickness in thousands of an inch or mm... Next removed the contaminants with Acetone... pick a hard surface to lay over a 600 grit black dry emery paper... rotate the clutch plate in a circle... you're just busting the glaze... don't get carried away remove too much material... You should end up with a friction plate looks dull like a new one as opposed to a shinny glazed one... recheck thickness... Finally check the pressure plates for bluing caused by localized heat... make sure they are not warped... consult the manual for a thickness range... now removed the contaminants with Acetone and wire wheeled them to erased the blue and also to generally scuff up the surface... you should end up with a dull surface free of Blue marks... Steps to check your clutch for drag... your gears can't shift smoothly if your clutch is part way engaged... 1 Place your bike on the center stand... 2 Start engine and establish a warm steady idle... 3 Squeeze in the clutch lever and shift into first gear... 4 Hold in the clutch lever and note if the rear wheel coast to stop... if it continues spinning trouble shoot the lever for travel and master cylinder for condition... open the oil filler and look at the clutch pack to note just how far the plates spread apart when you squeeze the lever... Ultimately you want the rear wheel to coast to a stop when the engine is idling and first gear selected with the clutch lever is squeezed in... Bike on its side is a simple way to shift the oil level to an angle in order to remove the clutch cover without spillage... Have a new gasket standing by...

-

If you see *continuous* temps higher than 220ºF or below 180ºF then trouble shooting is in order: Continuous engine temps above 220ºF or 104ºC is a problem and the proper order of items to trouble shoot are: 1)Faulty radiator cap... system should hold 1.1 pressure ratio... 2)Insufficient coolant... 3)Passages blocked in the radiator, hose or water jacket... 4)Air in the system... 5)Thermostat stuck closed... 6)Faulty temp meter or thermo sensor... 7)Faulty fan... 8)Faulty fan switch... Engine temps below 180ºF or 82ºC is also a problem... it means that the moisture produced during combustion is not getting hot enough to evaporate out the pipe as steam... instead that moisture will migrate to the oil and produce a milky white contamination... Note normal by products of combustion is water... . Every gallon of gas creates roughly 8 pounds of water vapor... we all have witnessed water escaping out of tail pipes on cold mornings... The sequence of events to trouble shoot are: 1)Faulty temp meter... 2)Thermostat stuck open... 3)Faulty fan switch... (stuck on)

-

Ths is the method of aluminum fork polishing I used to returned the factory luster of my RC30 forks... 1)Strip the factory clear coat with paint stripper... 2)Sand with fine foam sanding block in one direction only... you want to curve around the tube like Honda did and not sand down the length of the tube... 3)Polish with 3M gray micro fine pad... again only polish in one direction only... you want to curve around the tube like Honda did and not sand down the length of the tube... 4)Spray with clear coat...

-

Hiya... up grading a Lithium Ion battery is the quickest and easiest way to shed 6 pounds of unwanted weight but I’ve noticed the cost is not for everybody...

-

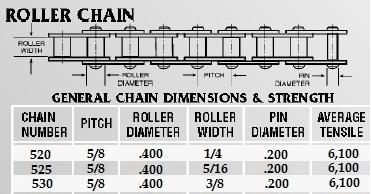

Stock factory chain is 530 110 links... the only difference between the sizes is roller width not chain strength... the wider the roller the longer the chain last...

-

As the RC45 Club's tech advisor I received this urgent photo and a request as to the reason why fire almost claimed this members RC45 ... Story goes that Bob and Pam Solloway of Coventry UK... a couple of RC freaks... were on the way to Misano WSB... Pam's RC45 caught fire while stopped at a light... the flames were beat back by bottle water from a passing van... they were lucky the incident did not happen out in the middle of nowhere for it would have spread rapidly to the fuel lines and then the tank... nothing is worst as watching bike flambeau... First call was to check the alternator quick disconnect at the transformer rectifier... I was positive that the QD had suffered enough resistance to heat and melt the insulation on the wires... the wires got enough to start a fire which all most consumed her prize... I seen this problem before... As I prepared my case for Pam I pulled the seat cowl off my RC45 to send her a pic of the quick disconnect in question... Mercy was I ever in for a shock... my quick disconnect was bad and about to turn my bike into a crispy critter...

-

Basics of Rake... Rake is defined as the angle of the steering head with respect to a line drawn perpendicular to the ground (left). A smaller angle, or less rake, is sometimes referred to as being steeper. Less rake = quicker steering and less straight line stability whereas more rake = heavier steering and more straight line stability... Basics of Trail... Trail gives a motorcycle stability because of the self-centering effect caused by the front wheel being behind (or trailing) the steering axis. Too little trail, and this self-centering effect is decreased to the point of instability. Too much trail, and the effect is so great that steering becomes heavy. Stock VFR Rake 25.5º Trail 95mm Shimming the rear shock 6mm will change rake and trail towards these numbers... Mod VFR Rake 24.5º Trail 92mm Count the number of chain links to insure you have 110... if you have `108 your cassette will cost you ride height because it is not at the 6 O clock position... Wrong... lost ride height... Right... correct ride height...

-

I bought an RC30 with tenacious brake dust that nothing seem to cut it... Only Mineral Spirits would cut it and return the luster of the calipers...

-

1999 Hard Starting, Winter Project

BusyLittleShop replied to Hingley's topic in Fifth Generation VFR's

For the system to work as designed on start up the butterflies must be 100% closed... this is because close butterflies equals sufficient vacuum... without sufficient vacuum the fuel cannot be drawn into the combustion chamber to support start up... the result is hard starting... the drill for cold or hot start is 1 100% close throttle for sufficient vacuum 2 Full choke on when cold no choke when hot 3 Hit start Eliminate the possibility that the throttle body butterflies are not closing 100%... if any any air is bleeding pass the butterflies then the metered flow of the idle air can not draw sufficient fuel to support combustion...