Leaderboard

Popular Content

Showing content with the highest reputation on 01/16/2019 in all areas

-

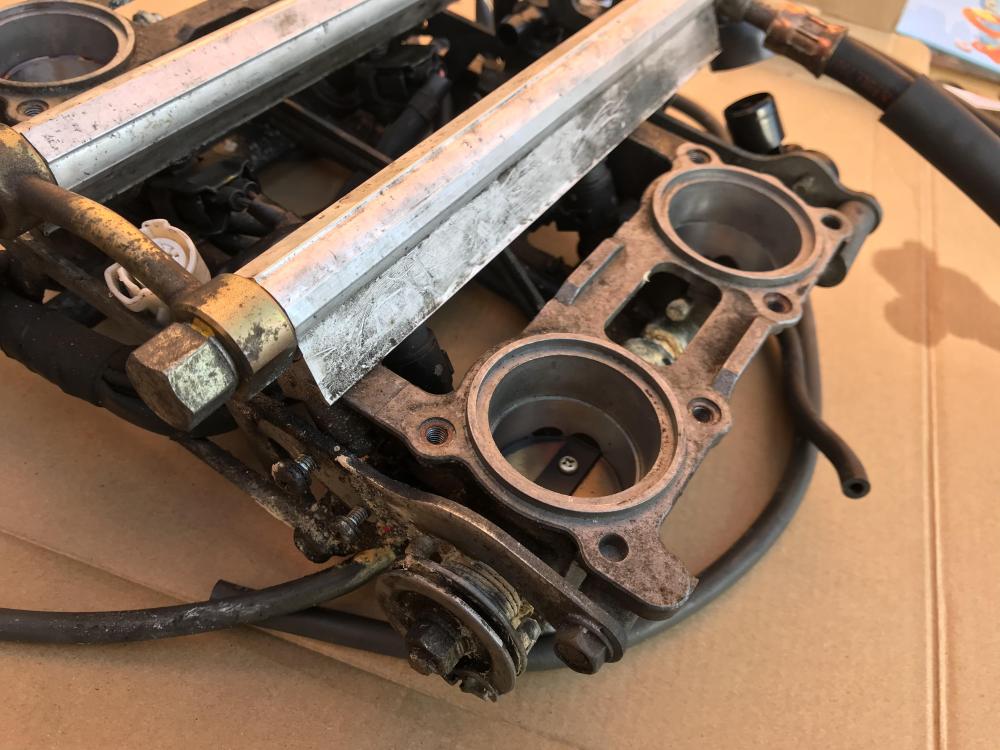

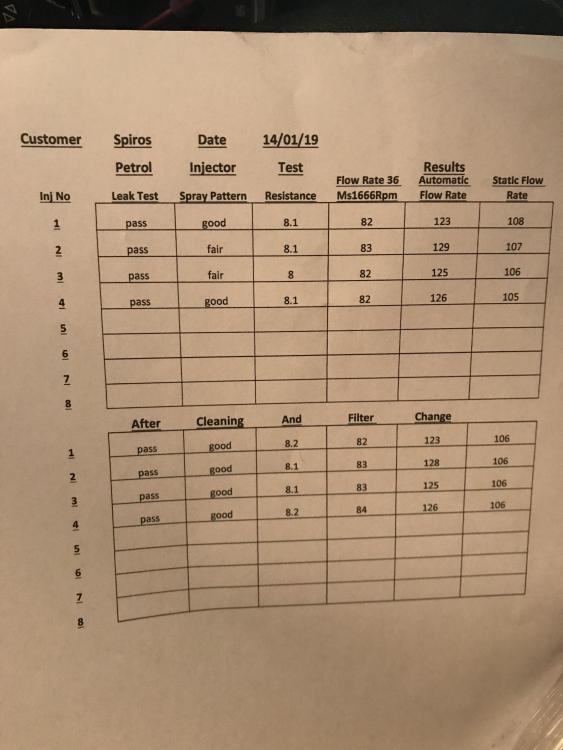

Last week I took the plunge and removed the throttle bodies. Was worried about rubber boots being too hard and brittle after 20 years and 70k miles. Anyways, had to buy an extra long extension thingie to reach the rubber boot clamps. Despite some pretty serious corrosion they came undone without stripping (got to push against the screw pretty hard). Ordinarily there’s no place for crowbars in motorcycle wrenching but some gentle application against the rim (working slowly along with some protection for rear cylinder head) popped rear boots right off. A little wiggle and the front boots also gave way. Here they are in all their filth and rust. Note the cardboard box is from a Vtech Christmas toy - I thought that was funny! Closeup of the butterflies shows some black buildup on the opening edge. Sprayed liberally with throttle body cleaner and broke out the toothbrush. Soaked butterflies on both sides a few minutes to break down the kak. My God, the sh!t that came out was biblical! Some of the cr@p on the cardboard “workbench”... One hour later throttle bodies are looking better but certainly not perfect. Some stubborn stains and corrosion remain after two full cans of cleaner and a few toothbrushes being sacrificed to the cause. I cleaned throttle bodies BEFORE removing injectors as didn’t want crud falling into any of the small holes when they were exposed. Allen key/wrench used to undo fuel rails. Ring spanner used to apply leverage. Fuel rails and injectors coming off all at once. Nice and neat! Here they are removed. Looks like some dirt and water ingress getting past seals for the injectors. This is where the business end of the injector fits into the throttle body. Injectors looking dirty but not overly so. Was expecting far worse given age and mileage, to be honest. Crusty buildup on front seal suggests rather a lot of cr@p had got past it. This stuff is HARD like ceramic! Removing some of the crud in the injector seats with “GENTLE” use of a flat screwdriver. You can see the dirt coming off on the tool. Much cleaner bore means new rubber will seal better when re-installed. I didn’t touch the cone shaped bit for fear of scratching. Injectors now removed from rail. Wasn’t sure if I should buy new or rebuild these. On the one hand they are 20 years old and have reasonably hard mileage on them. On the other, we have better fuel in the UK than in the US so they couldn’t be too bad inside. On the horns of s dilemma: 1. get these professionally rebuilt? We don’t have many petrol injector rebuilding businesses in the UK (possibly because our fuel is pretty good) 2. Do I rebuild them myself with some carb/TB cleaner and a 9v battery? Lots of videos on YouTube. Problem is I don’t get a flow chart or ultrasound cleaning this way. Just soak, spray clean, back flush and replace seals. Very DIY and cheapest option 3. Buy new injectors and be confident they are 100%. Most expensive option (around $160 plus shipping/taxes from US - UL prices are insane!) 4. Buy rebuilt injectors with flow chart. Cheaper than 3 above but how do I know if they have actually been cleaned properly? Also, LOTS of knock-off injectors being sold as remanufactured items on eBay so this is a minefield. Anyway, I was leaning towards the DIY option and bought some seals from the US in preparation. Then I stumbled across this listing on eBay: https://rover.ebay.com/rover/0/0/0?mpre=https%3A%2F%2Fwww.ebay.co.uk%2Fulk%2Fitm%2F302743465882 At that price it was certainly worth a visit so I drove down and met Dave Bennet in the flesh. Lovely bloke! Saw his premises and ASNU injector machine. He talked me through his process: spray clean; then ultrasonic clean whilst activating the submerged injectors; then back flush; final spray clean and flow testing. He had them done the very next day and I dropped by to pick up the flow chart below. They weren’t too bad as it happens, although two had a dodgy spray pattern that was fixed by the cleaning. Also got a nice cash discount over the already low eBay price! Seriously, everyone else quoted me 4-5 times that price which is hard to swallow when new units cost only slightly more. Here they are well packaged and numbered. Looking really good and I’m really happy with them. If anyone wants injectors cleaned I am happy to endorse BobBeck Injector Services in Warminster, CV34 6TH. His number is: zero1926888110 (mods, please feel free to remove if inappropriate. I have no connection to this business other than having injectors cleaned this week). He didn’t have seals/filter for me but was so cheap I can’t complain. Got a seal/filter kit arriving in a few days anyway so it all worked out pukka! New silicone hoses to be installed next week. Tempted to throw throttle bodies in dishwasher before assembly but not sure sensors would survive it. Anyone done this? Grateful for any advice, especially from anyone who has done this. Stray3 points

-

2 points

-

Ouch - keep us posted, this is actually my next planned mod... I know they will say, it would have been much worse without, but if no real advantage to having them, not sure if I will still buy. On another note - I actually saw a guy back into, knock down, and then drive partially up the side of a bike outside a burger joint. I pulled out my phone and recorded him lifting it back up and he got to the exit before I stepped in front and told him it was all on camera. He said he was just going to go to the back of the restaurant, but this guy was bailing had I not caught him. :)1 point

-

1 point

-

I saw your post on this earlier and will follow your lead. Got new silicone lines ready to go. Still thinking of running TB through dishwasher first to give a deeper clean (but no point if it is going to ruin the sensors). What do you think? Spot on - got a seal/filter kit on order from the USA. Will fit with silicone grease (same stuff as brake calliper seals). Spot on again! Had a coolant leak somewhere in there and will be replacing o-rings/clamps and hoses. Might go silicone... I guess you’re right, BUT, dishwasher has a rinse cycle that removes all soap residues. Soap is only active for a short time during the cleaning cycle. I will also be coating TB with ACF50 anti corrosion oil after. We run lots of aluminium items through the dishwasher without damage. Most modern frying pans are aluminium with raw bases - mine seem OK wash-after-wash. Same for baking trays and lots of other stuff - comes out the washer OK. So I’m not worried about aluminium corroding; more worried about hot water entering the sensors and damaging them. Is this a real concern or not? I know motorcycles can ride in the rain but hot soapy water is a different thing entirely.1 point

-

Its nice to see the injectors wern't to bad given their age and milage but looks like I should probably be seeing to my seals in the not to distant future.? I was wondering if the throttle bodies had to be removed to access two of the four cooling system elboes in the valley of the engine block (I'm not sure from memory)? Could be worth changing/checking the 'o' ring seals in them while the engine is in bits? Consider this...Dish washer soap is caustic... will eat aluminium/magnesium castings very quickly.1 point

-

Absolutely! Mine was a leaky mess as is. I yanked that BEFORE I did the MTB and my idle changed a touch, which tells me it wasn't exactly working per spec anyway. You can argue about flapper mods, and I can see both sides, but I will ALWAYS recommend yanking the PAIR, regardless. But if it's letting fresh air in you straight up won't get the right readings. Probably run rich and fluctuate based on how you're riding and how much air those valves are leaking in.1 point

-

You might want to replumb that thing, too. My vacuum lines were pretty crusty and leaking enough to throw a code on the MAP sensor, so I had to re-remove the throttle body and run new vacuum. It's not hard. Just did it one line at a time so I never got lost. So, since you've made the mess already, you might as well.1 point

-

The 4.9 version has a smaller plug that is completely oval where the 4.2 is bigger and has a flat side to the oval. I use 4.9's on the VFR and also on the MV F3 I work on. Also, just make sure that if you are sealing the headers up stream of the O2 sensor, use a sealant that is O2 sensor safe. some HT silicones are not. On that note, making sure that there are no air leaks in to the headers, up stream AND down stream of the sensor is extremely important in getting the best and most accurate results. Make sure that the PAIR system is completely removed and well sealed.1 point

-

1 point

-

NYC is probably the ultimate bike protection proving ground. Getting out of my Manhattan office today and noticed that someone moved my bike. By moved I mean from vertical to horizontal and then back to vertical. Looks like the frame sliders I got from T-Rex don't protect. Time to shop for a new mid-fairing...0 points