styran

Members-

Posts

45 -

Joined

-

Last visited

styran's Achievements

-

I have it back in right now to check the clearences but I remember it does not look bad. Looked like the rest of the journals

-

2002 VFR800A, ~50,000 miles. doing valve timing job, on the rear bank. heres photo for reference these two bearings are the ones on the front, closest to the cam timing sprockets: These 2 look good: Heres the one im worried about, (next 3 photos) back left. this one grabs my fingernail: How worried should I be regarding this motors longevity?

-

Amazon has some amazing bulk deals for these filters right now. I can get the shorter of the 2 for $2.25 each (PL14612) or the longer one for $4.6 each (PL14610) I understand these 2 filters are identical besides the length. I am debating which one to pick: 1. wondering if the longer option (PL14610) would be tough to fit with the radiator hose in the way (i've used a slightly shorter filter, and it was already a tight fit) 2. if i should just get the shorter filter (PL14612) just based on cost alone ($2.5 vs $4.6 each). I would love to hear your thoughts! sources: https://motorcycleinfo.calsci.com/FilterXRef.html#5

-

Bike used to shut off randomly, now has MAJOR grounding problems

styran replied to styran's topic in Sixth Generation VFR's

It was likely loosened accidently and forgotten about while my friend was replacing the main harness. The bike needed an immediate oil change before starting as the oil was heavily contaminated with fuel. You could see the separation of layers in the oil sight glass. With the bad ground, the injectors were leaking constantly, filling the cylinders with fuel to the point where it was leaking out the exhaust. I am guessing a lot of it washed down the cylinder walls. Unplugging the FI harness stopped the injectors from leaking while we were diagnosing the grounding problems Bike has been running top notch ever since the battery ground was properly secured. Its gonna be going offline soon for its first valve service at 50k miles- 15 replies

-

- electrical

- charging

-

(and 1 more)

Tagged with:

-

Check both 30A main fuses one connected to starter solenoid and the other near battery. Then check grounds. Check battery-to-frame ground (under gas tank hinge) and frame-to-harness ground as well

-

So @Grum, Should I replace them? I just replaced by buddies (the one with the electrical problem) CCTs at 41k miles. Mines only at 22k and starting to clack

-

No spark. No fuel prime. No FI light. help.

styran replied to Kobo's topic in Sixth Generation VFR's

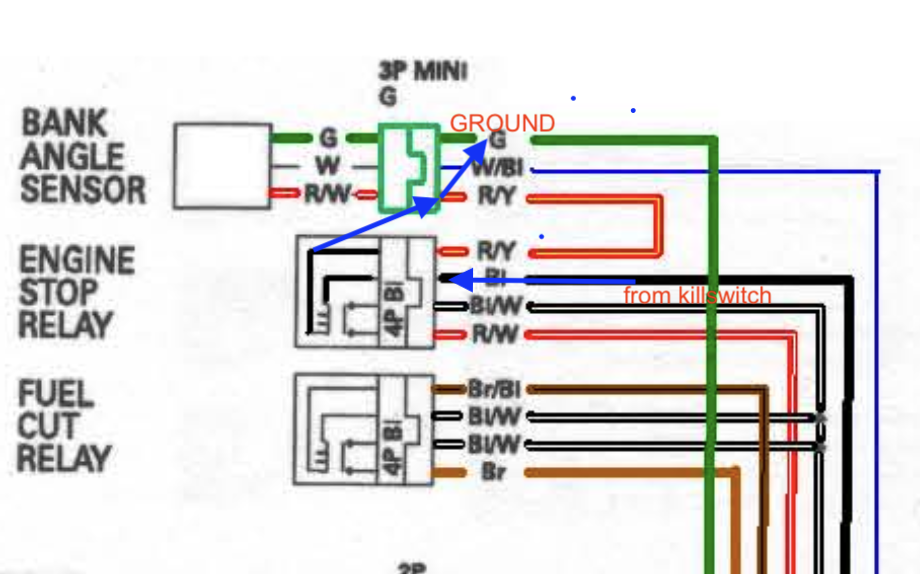

When me and his buddy worked on his bike after a big accident we could not get the computer to fire up, we looked at the diagram and the bank angle sensor was missing. We jumped the outside pins of the bank angle sensor connector and the bike fired right up. Check the fuse first then this may be worth a shot. -

Bike used to shut off randomly, now has MAJOR grounding problems

styran replied to styran's topic in Sixth Generation VFR's

Problem has been found. I have told my buddy several times to both grounds but only checked the main harness ground and never checked the grounding cable that goes from battery negative to the frame under the gas tank hinges. It was quite loose. He has taking his bike for multiple roadtrips and has had no issue since. Thanks for all the help!- 15 replies

-

- 1

-

-

- electrical

- charging

-

(and 1 more)

Tagged with:

-

The 2002 VFR800A is my buddy's bike. The 07 above is mine. I have been posting on his behalf. He believes he has found the problem. I have told him several times to both grounds but only checked the main harness ground and never checked the grounding cable that goes from battery negative to the frame under the gas tank hinges. It was quite loose. Once he takes his bike on a couple test rides I'll update the other post. Just wanna make sure we've got it fixed 100%

-

2007 VFR800 with 22,000 miles (32,000 km) See youtube video below: Are these the dreaded CCTs? Is it normal to get them sounding like this with this little mileage? My buddies 02 started rattling at 44k miles.

-

Bike used to shut off randomly, now has MAJOR grounding problems

styran replied to styran's topic in Sixth Generation VFR's

we inspected that exact yellow ground block in the front subharness in your pictures above. terminals were silver and in good condition- 15 replies

-

- electrical

- charging

-

(and 1 more)

Tagged with:

-

Bike used to shut off randomly, now has MAJOR grounding problems

styran replied to styran's topic in Sixth Generation VFR's

Battery is healthy. Checked where battery bolts onto frame and that is tight. Checked where main harness bolts to frame and that is tight too. with key off, 0V on frame with key on, killswitch on, 3.3v on frame something is shorting somewhere. unplugging the ESR shows 0v on frame. we then depinned the ESR connector, we removed the black and white wire spade, that did not change anything, still 3v on frame. We then removed the black wire spade, coming the killswtich on the handlebar. we got the relay to click by jumping the correspoding relay pin with battery postive. 3v on frame. (this is the same as killswitch on, we are replicating that by jumping to batt positive) from this we assume that the B/W and B wires are not causing the short. so, when the relay receives 12 V from black wire, that is being grounded to G wire via the bank angle sensor. the bank angle sensor connector is currently being jumped. G wire to R/Y is being jumpered could that be causing the issue? we have gotten the bike to start before by jumping the bank angle sensor a very long time ago so we dont think this is the problem. another interesting detail is pushing the starter button causes 3v on frame with the ESR in or out.- 15 replies

-

- electrical

- charging

-

(and 1 more)

Tagged with:

-

Bike used to shut off randomly, now has MAJOR grounding problems

styran replied to styran's topic in Sixth Generation VFR's

We replaced the subharness with an older subharness and still had the issue with positive voltage all over the grounds. We have not tried cranking yet, if the dash even turns on its super dim. computer is not in because we do not want to fry it. probing the frame with the conditions i mentioned above will result in positive voltage (4 or 9V instead of ground) we tested continuity on the ignition switch and it was good. if we turn the KEY to ON/OFF, with the dash unplugged, and the killswitch on STOP, the frame and harness grounds are GOOD. with either the dash plugged in or the killswitch on RUN, all grounds are BAD ONLY with key ON and fuse mentioned in previous reply. dash unplugged and killswitch RUN with the engine stop relay plugged in will cause it to click but will make all grounds BAD. without relay, grounds GOOD. we have removed the BAS and just left the connector jumpered (pins 1 and 3 connected). we originally thought it was causing the issue. the bike electronics are stripped down to only the essential components. when the grounds are bad, they are bad absolutely everywhere except the batter negative and the bolt where the battery negative bolts onto the frame. even the bolt where the main harness grounds to the frame is also bad with the conditions above. before it got this bad the dash was lighting up like a christmas tree with erroneous speed readings with the bike stationary the fuel cut off relay was buzzing continiously as well. it has gotten so bad that this does not happen anymore and we have the issue mentioned above in the described conditions. this is a very strange problem and i have never had anything like it before- 15 replies

-

- electrical

- charging

-

(and 1 more)

Tagged with:

-

Bike used to shut off randomly, now has MAJOR grounding problems

styran replied to styran's topic in Sixth Generation VFR's

@Grum We added an extra power wire to the connector and replaced the burnt spade with the spade from an old main harness. That did not solve the problem. The bike no longer starts now. Turning the key will cause some intense flickering and erroneousness readings for speed on the dash. The bike will no longer start as well. Additionally, the bike starts leaking fuel out of the exhaust headers onto the ground. Disconnecting the FI harness solved that issue. With a power probe we found weak battery voltage on all parts of the frame (which should be ground) and EVERY wiring harness ground wires. Grounds near gas tank hinge were inspected and in good condition. We've isolated the problem to the "START, BANK ANGLE SENSOR FUSE" circuit. The frame is powered by the weak battery voltage when the key is on and the fuse mention above is in. Having the engine stop relay plugged in, bank angle sensor jumpered, killswitch run, with key on will cause power to be sent through the frame grounds. Without the relay the frame grounds and wire grounds normally with key on. Plugging in the dash with key on will also cause the same issue as the relay with key on. Very strange. Either the dash or the engine stop relay being plugged in will energize all the grounds. Swapping relays also had the same bad results. We believe the issues is involved with the front subharness (big grey and blue connectors). We have inspected the yellow grounding block on the front subharness and it is in good shape with no obvious burn marks. To avoid frying expensive computers, we have removed the ABS module, pulled all ABS fuses, removed the ECM, removed main fuse B. All headlight fuses and connectors have been pulled as well. We found that the tail license plate light was energizing the grounds at first, after unplugging it, the problem still persists. Also, the issues still persisted with the front subharness replaced with an old one that was involved in the accident. Any ideas?- 15 replies

-

- electrical

- charging

-

(and 1 more)

Tagged with:

-

Bike used to shut off randomly, now has MAJOR grounding problems

styran replied to styran's topic in Sixth Generation VFR's

Is this good? https://www.amazon.com/FLYPIG-Starter-Solenoid-Connector-CBR1100XX/dp/B06XC7KY6S I'm not sure if it has tin spade connectors. Will definitely splice the full red wire- 15 replies

-

- electrical

- charging

-

(and 1 more)

Tagged with: