Search the Community

Showing results for tags 'shim'.

-

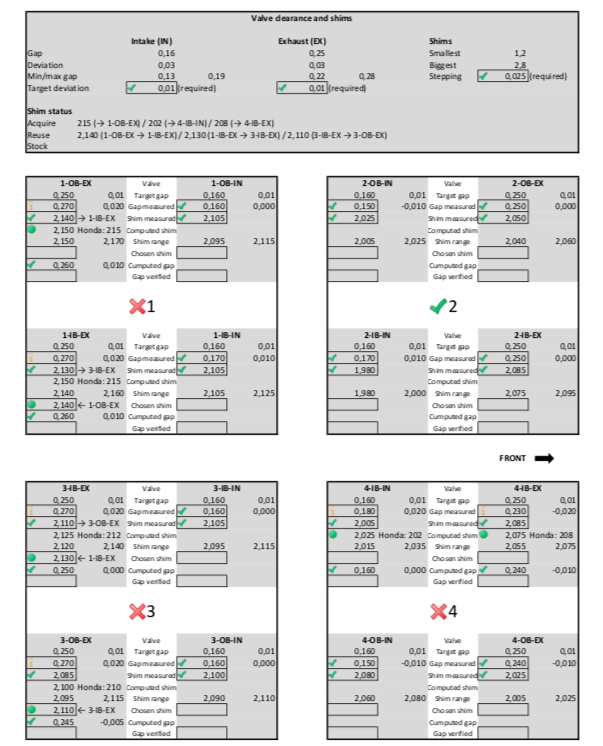

Hi guys, I have not yet needed to change any shims on my 1996 VFR 750. I have checked them a couple of times and changes are so small that it could be my skills being inadequate with the micrometer and feeler gauge. Recently I read it is better they are off target value to the "smaller side" - I don't understand this argument... maybe somebody can explain this? But it got me thinking, is it better to "hunt" being as close as possible to the target value. With my latest measures I realised that I can get them all better than 0.01 mm with just 3 new shims and moving some others around. What do you do - leave the shims as long as clearance is within spec or do you go for the closest to taget value every time?

-

Greetings - New to VFR and forum. I recently acquired a 1991 VFR. One owner, but came via another party so do not have direct access to past history. Bike is not quite as nice as Treestylist,... 70K+ miles. Did come with extra set of wheels and front float rotors (from 4th gen?), as well as a box of misc. air filters, oil filters, manuals gave some hope it was owned by responsible person. Also has a FOX rear shock, so thinking owner did have right idea in mind. Was a great deal, but had to buy - no ride. Had anticipated a complete go through. Had not anticipated bent fork tubes. I have now read through many past forums on suspension and looking for sage advise. I have new tubes on order with Frank's - Have all new bushing, seals, head bearings. Made a stem nut adjust tool so if anyone local needs to borrow can do. Have head reassembled but trying to find an ounce spring scale to adjust to the Honda spec of 1-1.5kg pull at leg. In tear down have discovered that this has RaceTech 1kg/mm springs with a preload made from a thin wall electrical conduit,...not to thrilled with that part. These may be on the stiff side as rider weigh in at 165, no luggage? It has RT compression gold valve with a set up for their "C33" stack - NO bleed hole? Not clear if the rebound piston is stock or RT? It has 10 17mm dia. x .01 mm shim stack. - NO bleed hole. Can someone explain what the bleed hole does as it seems to me that the top of rebound piston has a (by-pass) valve that would allow oil to be forced to the top side that can not go though the compression stack and therefore "Bleed"oil to the top side?? What would have been the result of this being used without the bleed holes? IT must have worked to some degree? I only rode it for a very short distance when loose head bearing (result of whatever happened to forks?) came to light. I did notice it seemed to dive badly on braking. Have called RT to see if they could provide original info from owners name,..They have name in record but no spec's. They are nice but answers are cryptic at best. They suggest that I order a complete new shim set at $60+ and with that get a new "code" to get set up for me. Not unreasonable but think that this set up could be close to correct. I just want to verify the rebound stack - my understanding is that if the rebound is still stock then may not be adequate for the stronger springs and be overpowered on rebound. What the logic is of the bleed holes and should I add these to both compression and rebound? How is it that no one seems to have put together a spreadsheet of RT data so we can do our own calculations? Would love to hear from 3rd gen owner who have RT set up and any clues of what works and what does not.

-

From the album: MadScientist's Gallery

-

I finally worked up the courage to remove the camshaft to check the shim sizes. It was pretty easy actually. Slow and easy. When it came time to put the buckets and shims back into place I couldn't keep the darn shim in place. Even with a dab of oil as suggested the shim kept sliding out of place when I started to turn the bucket over. I finally resorted to putting the shim directly on the top of the valve stem and then put the bucket on. I don't see why that should be a problem but every guide/article I've read says to put the shim in the bucket and then put the assembly in place. So how do you keep the shim in place?