Ladajo

Members-

Posts

21 -

Joined

-

Last visited

-

Days Won

1

Ladajo last won the day on July 5 2019

Ladajo had the most liked content!

Profile Information

-

Location

RI

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Ladajo's Achievements

-

-

-

Motorcycle won’t start – fuel pump not getting enough voltage.

Ladajo replied to darkshad's topic in Sixth Generation VFR's

Yes, I agree, there is definitely some resistance in the loop. I was pondering last night on whether it is better to monitor at the battery or out on the bike on the 12V main switched bus. I am kind of leaning towards the latter as it seems to me that this is the best indicator of a failing ground, fuse holder, or multi-pin plug. I see your logic about monitoring directly at the battery, however if I do this, I will not see a distribution system failure, only when it is too late. Thoughts? On the other note, I will do some checks this weekend and look for high resistance points from power to return, as indicated by half-splitting in the wiring and finding the largest voltage drop(s). From there I can assess if I need to redo/repair/clean any connection points or faulty wires (or undersized for load). Every connector I have opened has looked good, no heat marks, no corrosion. However, as noted I am losing a volt or more somewhere(s). And, it seems to be higher when under heavy load, up to the order of ~1.5 VDC. I do appreciate your clear and well grounded (pun intended) knowledge on this bike. It is clear you have done some mileage (pun intended again). All your comments and thoughts are welcomed by me. Historically, I was a 250 dirt biker, and then spent some time on a GS700E, and then back to dirtbikes (and snowmobiles), and then this bike. While I have owned it since new, I do not ride it as much as I wish, thus she is very low miles for her age (16780). I put on 8 miles per day in commute, and then a little outside of that sometimes on the weekend. I am hoping to do some more touring in the fall. The last good run I had was a number of years back in VA and WV, with a couple of buddies. We made a multi-day run from Chesapeake, Virginia up into the Blue Ridge Mountains in West Virginia. Beautiful riding, except the flats in VA (smoking hot, long and boring). -

Motorcycle won’t start – fuel pump not getting enough voltage.

Ladajo replied to darkshad's topic in Sixth Generation VFR's

Ok, so I thought it may be reading a little low. And with your prompt Grum, I did check when I got home today. It appears I am dropping a volt in their across the connectors and fuses. I will do some half splitting this weekend o ce I move the 12v wire for the meter to the 12v pin on the Bank Sensor. I did adjust the idle to 1200, and it makes a difference in generated volts at idle. Photos below. Short of the long of it, make sure your idle is set right to help limit electrical heating due to higher amps at lower volts. I also let it run with the fan on and off to see how she was handling the load. All good as you can see in the pics. I did try it at idle with fan on, and high beams, and she didn't like that. Got a higher voltage drop, and definitely was pulling on the system she did run, and with some throttle was ok, however based on the experiment, don't run at idle with high beams on for extended period. Oh, for the record, I do have the 115mm rotor / stator kit. Look at rpm and temps in the pics as well so you can see fan status and where I had revs. -

Motorcycle won’t start – fuel pump not getting enough voltage.

Ladajo replied to darkshad's topic in Sixth Generation VFR's

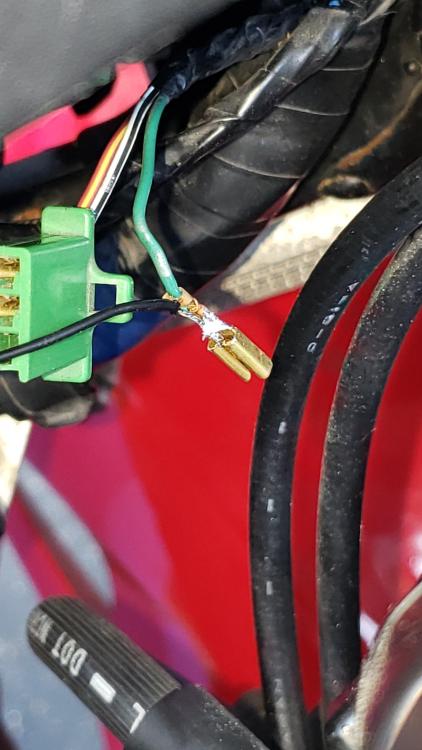

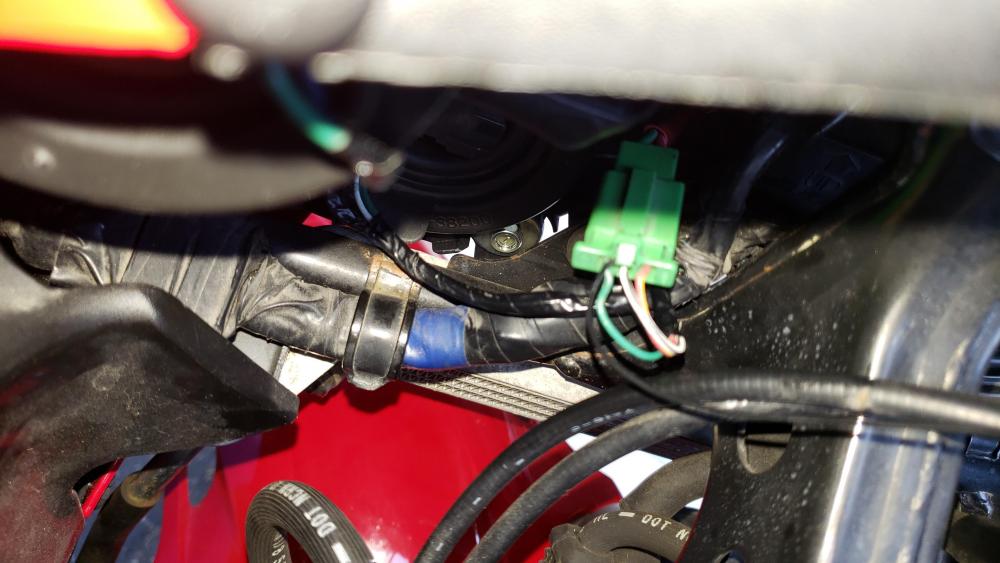

Riding to work this morning, I had 13.1 to 13.2Vdc on the meter. I did notice my idle is a little low, currently at about 800-850. I will tweak it up a bit. When it goes to full idle, the generated volts drop low and the system is floating on the battery, and drawing it down. When I played with the throttle a little to bring it up to 1100 to 1200 rpm, to simulate where idle should be, I was then getting volts around 12.5 to 13. This showed me that the idle setting ABSOLUTELY matters for these bikes due to generated power. Later today, when I get home I will compare with my Fluke between direct from the battery to where I hooked in the meter. I will probably wait until the weekend to move the (+) wire for the meter from the handlebar brake switch hot to the Bank Sensor green plug under the front cowl. I used a 13/64" micro screwdriver to pop the terminal out of the plug body, literally pushed right out, easy day. Quick solder job, and then press it back in and make up the connector and done. For anyone with a soldering iron, a tool to get the pin out of the plug, and the $10 meter, this hook up is clean and fast. Literally 15 minutes if you have your tools at hand. I highly recommend this as the go to place to hook up a DC Voltmeter for the 6th Gen. -

Motorcycle won’t start – fuel pump not getting enough voltage.

Ladajo replied to darkshad's topic in Sixth Generation VFR's

I will check. I was thinking it might be the temp sensor. Hadn't looked it up yet. Either way, just using the ground for now. Later as I said I will switch to put both wires there. My sense is it might be reading low. I have it on the charger tonight as I had done multiple ons with no run, as well as starts -

Motorcycle won’t start – fuel pump not getting enough voltage.

Ladajo replied to darkshad's topic in Sixth Generation VFR's

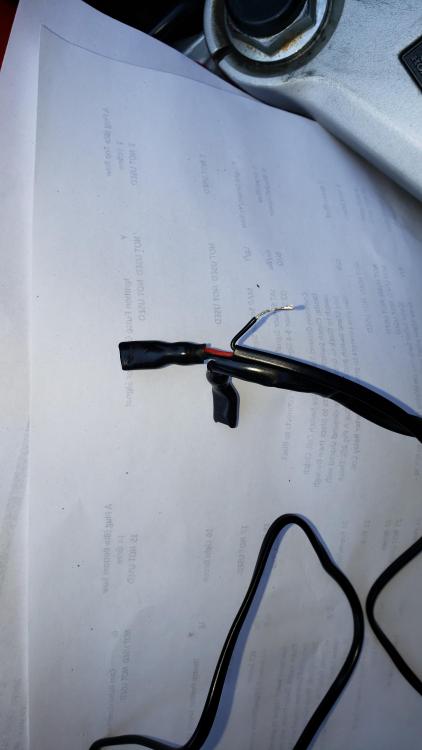

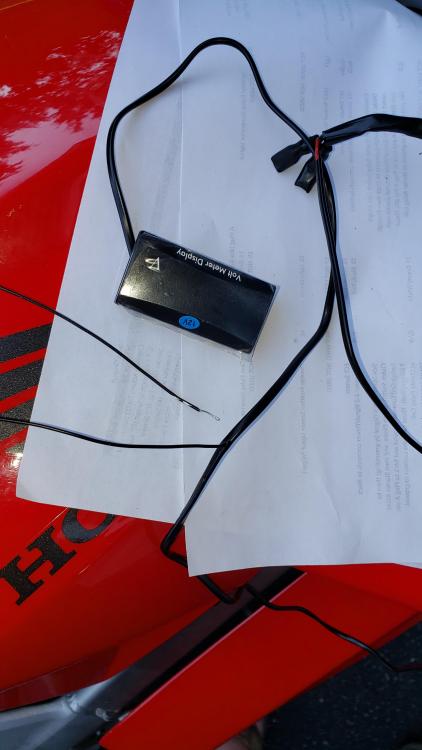

Installed my voltmeter. Decided to mount it between ignition key and head stock. Looks like a good spot. I initially thought to wire it to the 12volt wire feeding the handlebar brake switch. Then after soldering that to the hot side (switched with ignition), I couldn't find a decent ground point. Sooo, I poked around and found the green plug accessible under the cowl on the left. Popped out the ground, soldered my negative to that, reinserted and Bob's your Uncle, and possibly Cousin as well. Sometime later I will move the Hot side to the Black/White switched 12v on the same green plug. Photos below. -

Motorcycle won’t start – fuel pump not getting enough voltage.

Ladajo replied to darkshad's topic in Sixth Generation VFR's

14.6V highest recorded at about 7k rpm. It stabilized at that level around 3.5k as I recall, and then didn't really get any higher. Definitely regulating... 🙂 I think I will connect it to the fuse block, and the 10a fuse off the ignition switch. Thanks for your help! -

Motorcycle won’t start – fuel pump not getting enough voltage.

Ladajo replied to darkshad's topic in Sixth Generation VFR's

I received and installed my new Regulator Rectifier. It came really fast, shipped international Fedex from Canada. It was estimated for no later than Friday, and arrived yesterday. So, after install (mounted right in, and plugs hooked right up - no mods required), then with an oil change (3.3 qts Castrol Power 1 4T 10W-40 full synthetic & a Purolator Pure One PL 14610 3.25 inch filter) conducted while I was grilling short ribs, then dinner, then testing all good. After dinner I put the fairings back on, and then rode her to work this morning. Yay! I will install the little voltmeter I got from Amazon this weekend, and then will have a running indication of system voltage at all times. 🙂 I plan to hook this up to the relay next to the battery, so it is only on with the bike in run. I think the new MOSFET RR will reduce the heat burden on the stator, as well as provide a better regulated system voltage, in addition to being able to provide up to 50 amps for load, which is much better than the old RRs (OEM and Electrosport). Hopefully, this means I won't kill another stator or computer for the remaining life of the bike. On that note, I do have two stators in my garage the OEM, and the Electrosport which are good cores if anyone is looking for rewind stock. I also have the OEM RR, and the Electrosport RR for science projects, since they are both done. The OEM shows one diode leg in spec. when cold, however it is actually cooked, so when it heats up that leg goes away. The Electrosport, as noted, does rectify, however it is not regulating, thus it is dependent purely on AC in level for the DC out level. Voltmeter: https://www.amazon.com/gp/product/B07SRP2XD5/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1 Ricks MOSFET from Ebay: https://www.ebay.com/itm/Mosfet-Regulator-Rectifier-For-Honda-VFR-800-RVT1000R-RC51-2000-2007-2008-2009/232547357017?ssPageName=STRK%3AMEBIDX%3AIT&_trksid=p2057872.m2749.l2649 -

Motorcycle won’t start – fuel pump not getting enough voltage.

Ladajo replied to darkshad's topic in Sixth Generation VFR's

Hi Grum, Thank you. I did a little more digging and found out it is the regulator feedback wire which the OEM style RRs use as a reference voltage for regulator output. When red is, the RR cranks up output to charge a low battery. When red is high, the RR lowers output voltage to compensate for a charged battery. If the wire is cut or has degraded connections, thereby dropping voltage across each one, the OEM style RR can reach a max output condition and exceed voltage ratings of components on the bike. Apparently light bulbs are the first to go. The newer style MOSFETs do not use a separate voltage feedback sensing line, as they monitor the actual outputs and regulate that way. This helps prevent the bad feedback line over voltage issue. My feedback line rang out nice and clean both for resistance, and for dropped volts under power. Also, my DC output varies directly with Alternator spin speed, indicating an unregulated full wave bridge. I also hope there was no damage when I was testing. I did not leave it up high, it was fully transient, and I only did it once. Given I was less than 150% operating voltage, and short duration, things are probably ok. Once I get the new RR,I will go around and check all the lights, as they seem to be considered the weakest link. Additionally, I bought a stick on flat face DC Voltmeter, which I will hook to the 12v monitor wire to have a running indication of bike voltage. This will provide better notice of any charging system or other electrical issues, hopefully prior to expensive damage. -

Motorcycle won’t start – fuel pump not getting enough voltage.

Ladajo replied to darkshad's topic in Sixth Generation VFR's

I just ordered a Rick's MOSFET Regulator Rectifier. Found it on Ebay at RaceTechElectric for $100. Should be here in a few days. More thumb rolling while I wait for it. The previous one was an ElectroSport ESR438. Put it in about 4 years ago. Piece of shit. I don't have any wiring issues, or hot connectors. Seems to be a quality issue. Let's see how the MOSFET holds up. I am considering direct connecting it to the battery. However, I need to look at the Black monitor wire before I do that. As I understand it feeds 12V to some essential circuits. The Rick's write up says "we do away with that". Without having it in hand, it seems that maybe they jumped that pin in the RR connector to the Red +12V output. -

Motorcycle won’t start – fuel pump not getting enough voltage.

Ladajo replied to darkshad's topic in Sixth Generation VFR's

Ok, I got the replacement ECM ECU. I compared pin readings, and B12 was not shorted. All else checked out. Of note was that B1& B2 are hard connected I eternally, as are B14, 15, & 16. After not finding any obvious issues with other components on the 12V shared line connected to B12, I installed it and bike fired up. 🙂 Being sceptical as to why my old ECM ECU failed at B12, I made some checks on the Altenator and Regulator Recitifier power generation and regulation. At idle, all looked normal, I rev'd up and down and saw good readings from Alternator, and then checked regulation. Not good. Was at 19V and decided it was not regulating the voltage. Note to self, check regulated voltage first next time. Sooo, I think I have a bad RR and it fried my ECM ECU B12 12V input with over voltage, causing a short to ground (pins B14/15 &16). Now I feel much better about root cause. And, having caught it, believe I will not fry my ECM ECU B12 12volt feed once I replace the RR. This is going to be my third RR for the bike. -

Motorcycle won’t start – fuel pump not getting enough voltage.

Ladajo replied to darkshad's topic in Sixth Generation VFR's

Thanks for the feedback. I just was out there and forgot to verify B4 & B15. Gah! I will go back out, and then fix the spreadsheet accordingly.