-

Posts

172 -

Joined

-

Last visited

-

Days Won

2

Content Type

Forums

Profiles

Gallery

Blogs

Downloads

Events

Everything posted by BartmanEH

-

I'd say there's a good chance your Secondary Master Cylinder (SMC) is pooched. If it wasn't before the original owner put the hose clamp on it, then it might well be damaged from the hose clamp anyway. Odds are the cylinder is OK and you just need the Piston Set. I think your SMC is pulling in air rather than refilling from the rear reservoir as it should.

-

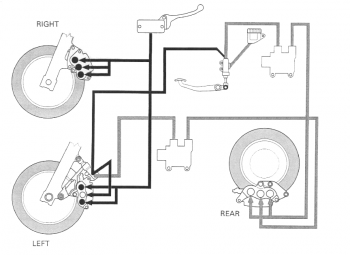

Jay, the photo in "G. Left Front Caliper, Inner/Centre Bleed Screw" shows actuating the SMC, but I think this line is done with the rear brake pedal - please confirm. Also, for the record, I never remove the front left caliper for fluid replacement - I just manually actuate the SMC with the caliper in place. Works fine and you don't risk wearing out the mounting bolts or squeezing the pads together making reassembly difficult. I'd also like to point out that with speedbleeders, when doing the SMC line, if you don't close the speedbleeder on PCV, the rear pedal will not force the SMC back out very effectively - most of the pressure seems to bypass the SMC and escape out the PCV speedbleeder. I figured this out too late after doing two bikes' fluid replacement. For that line you really are better off closing the valve between SMC squeezes. The problem is that the speedbleeders have sealant on the threads and don't like to turn easily and will get the sealant worn off quickly if you do close and open it so many times. I'm going to look into getting a fancy (expensive) Stahlbus bleeder for at least this one troublesome position - they're designed for maintenance free opening and closing.

-

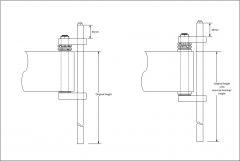

That's not quite correct because the measurements are made from the top of the triple clamp to the top of the fork. I whipped up a drawing to help visualize the situation: The left version represents the stock bearings. The right version represents new bearings that we presume have a taller stack height (which the evidence shows probably not to be true or at least very little). For the sake of argument, assume the new bearings have a taller stack height. The effect is that the upper triple clamp is raised off the steering head frame. If you place the forks in the triple clamp at the same original height which is measured relative to the triple clamp, you have effectively raised the forks in the frame by an amount equal to the stack height difference of the new top bearing versus the stock bearing. You have also spread the triple clamp and steering stem so that the forks are secured father apart by an amount equal to the stack height difference between the stock and new bearings. If you want the same geometry after putting taller bearings in, you have to lower the forks in the triple clamp to compensate. The effect of taller bearings is to lower the headstock if the fork height above the triple clamp is maintained.

-

From the album: Steering Stem

-

I don't understand why the forks would have to be raised to compensate for the taller tapered bearings. It should be the opposite. If the All Balls tapered bearings stack taller than the stock bearings, then the triple clamp will be offset higher up off the steering stem head of the frame. If you then set the forks to the same height they were with the stock bearings, they will effectively have been raised in the triple clamp by the height difference between the stack height of the tapered versus stock bearings. If anything you should have to lower the forks in the triple clamp to match the original geometry. I'm not claiming to be a particularly discerning rider - I'm not aggressive or experienced enough with suspension issue, however, I must say that this is my impression with my test rides after putting in the tapered bearings - the bike wants to fall into corners more than before with the stock bearings. I set the forks to exactly the same height i had with the stock steering bearings - 46mm from fork shoulder to triple clamp - and the bike really wants to fall into to corners and I need to keep force on the bars to stop it from falling into the turn more. I plan to lower the forks a bit to see if I can get a more neutral attitude in corners. Seb/Rice, what do you think? Do you agree that taller bearings put more space between triple clamp and frame and therefore effectively pull up the forks, steepening the rake and causes steeper turn performance? Please explain why you think one needs to raise the forks - I think they need to be lowered.

-

Seb, really? The All-Balls tapered bearings I just put in last night seem to be about the same height. I'm discussing this in another thread. V4 Rosso points out that if the tapered bearings were significantly taller than stock bearings that there would be a gap between the lower dust shield and the frame's steering head. Based on my inspection, there's no gap so the bearings must be awfully close to the same height. I can see how the steering and turn in etc. might feel different with the tapered bearings so one might adjust the geometry to suit. What I'm trying to determine is if I need to adjust fork height strictly to compensate for the tapered vs. stock bearings. I'm leaning towards believing that there shouldn't be a difference based on the evidence above.

-

See? That's why VFRD is the best place on earth - 'cause there's peeps like you what are way smarter than me! I took a look at the lower seal and took a picture: It looks pretty flush. I guess that's the best evidence that the All Balls bearings must be pretty close in height to the original stock ball bearings. Thanks for the tip!

-

From the album: Steering Stem

-

From the album: Steering Stem

-

Let me correct my statement a bit - I found my bike wanted to continue falling into a turn once in a turn. So I was incorrect in calling this too much turn in. Once in a turn, I had to hold the steering to counteract the turn. Dang, I wish I could find that thread that talked about accounting for tapered bearing height difference by adjusting fork height after installing tapered bearings. Grrrr. EDIT: found the thread here. Need you guys to review it and comment on fork height with tapered vs. stock bearings, please!

-

I didn't measure them with a caliper but they do look about the same height. I read in another thread that you need to change the fork height to account for the tapered bearings (can't find the thread - searching with this forum software is really impossible - you get thousands of hits). I found my bike turns in a little too easily for my liking. The fork height was 46mm (5mm more than the FSM). Should I reduce this a bit towards the FSM 41mm?

-

How much should I change the fork height to account for the All-Balls tapered bearings versus the stock bearings? Update: I got the old races out just using a screwdriver as a drift. There's two large openings in the race seats to access them so it was easier than I thought. I thoroughly inspected my race seats and don't see any cracking - I was worried after reefing on them like an idiot (read above posts) that I might have damaged them. I guess I was lucky. I'll post some photos later for the record for future peeps trying to figure this out. I seated the new tapered races using the old stock races. This is necessary as the new races go farther into the steering head than flush - they are recessed into the stem.

-

Well I think I found the info posted here: So I think I'm gonna get one of those Pit Posse tools as it will fit - with it's minimum size of 29mm - up through the race which is a wider opening that the bearing's ID of 30mm.

-

Generally all the Honda steering heads are the same. Check out this thread on the Goldwing. The guy makes a homemade bearing driver using a large washer that he grinds to fit in between the race and the stem to drive it out. Granted the VFR has an aluminum frame and that old Goldwing has a steel frame but from what I've read, there is a lip and a bit of a gap above the lower race on our VFRs that tools like drifts can catch directly. I'm thinking the Pit Posse tool might work nicely. It has a minimum opening of 29mm. Will that fit through the race? As I understand it the races are different sizes. Can someone confirm if the lower race has a 29mm opening?

-

I worry that the tapping, on each edge, will cause wear of the race journal due to cocking the race sideways a bit with each tap. Same with taping it in using the old races etc. As long as your tapping one side then the other, it's gonna put an offsetting force on each side jamming it into the side of the race journal. This looks like it might work for removing the races. Thoughts?

-

Steering Head Bearings - Secret to Installing the Lower Race?

BartmanEH replied to VFR800R's topic in Maintenance Questions

Not sure which one you mean on Amazon: Pit Posse bearing press Can you provide a link please? -

I might make one of these: To tap out the old bearing races like this guy did. This ST1100 thread talks about a kit one could borrow to do this job. That seems like a stellar idea. The thread seems to pretty much hit dead ends for me. I was thinking of joining the ST forum just to get a hold of this guy to see if the set can still be borrowed.

-

Um, Veefer buddy, kinda looks like you got a nice homemade race reemer there in the bottom pic just to the left of the bearing tool kit. Fess up - did you make/borrow a jig to get the races out of the steering head?

-

Let us know if it works. I'm skeptical. From what I've read, the lower race has a tiny protruding lip that's difficult for anything to get purchase on. That tool set's handle is pretty short and likely won't reach all the way down from the top of the steering head.

-

Steering Head Bearings - Secret to Installing the Lower Race?

BartmanEH replied to VFR800R's topic in Maintenance Questions

Hey Joel et al, how do you know when the bearing races are seated fully when using this technique? As SebSpeed says above, you can hear the difference in sound when taping them in but with this homemade press, which I like because it should help maintain better alignment, how can you tell when the race(s) are seated? Just based on the torque? -

I'm guessing the 6th gen steering head part of the frame is just a lot stronger now than the previous gens - i was really reefing on the breaker bar to try to get rid of free play. Definately I was lucky.

-

Is it obvious when the frame cracks? Can you hear it? How can't be sure I didn't crack mine? What did Ralph do about his cracked frame?