monstar

Members-

Posts

108 -

Joined

-

Last visited

-

Days Won

3

monstar last won the day on November 11 2020

monstar had the most liked content!

About monstar

- Birthday 09/24/1976

Profile Information

-

Location

East Bay, CA

-

In My Garage:

2003 RC51 RVT1000R SP2 (SOLD)

2002 CRF450R Supermoto (SOLD)

1995 VFR750

monstar's Achievements

-

IMG_0959.MOV Welding exhaust and subframe brackets for the exhaust hangers is done. Wrapping the headers with header wrap. I'll post pics when done. Still sounds pretty good with mufflers on it. iPhone audio doesn't do it justice, it's still pretty loud.

-

A little too racey, thanks. I have become my younger hooligan self around my neighborhood. 98-99 RR swingarm. Not sure exactly how short but I think atleast an inch. It's definitely not bad at all though, still very stable and handles like a much lighter bike... would like to see what it weighs now. Took awhile to dial in the ride height/geometry, got lucky in that respect.

-

Just wrote out a long post and somehow I lost it trying to add attachments. I'll give the short version: -Sorry it's been forever! Life (wife, baby, work, move, property work, etc.) -Been quietly working on the bike I bought 5-6 years ago and rode twice. -Since the last time: cbr900 swingarm, honda/suzuki hybrid dogbone-linkage, suzuki shock, 180/60 rear, 520 chain and gearing, gp linkage, version 1 exhaust (pretty but not well thought out), version 2 exhaust (super simple and almost done) bodywork and subframe pretty much sorted, brackets, blah blah blah. Just trying to tie loose ends and finish the final welds and ride. I did actually have a few shake down runs with half an exhuast. There were a few minor things I needed to address but those I believe are taken care of. I was surprised of how well the suspension and handling came out. It is nothing like the sport tourer I bought 6 years ago. I might dare to say it's funner to ride than my rc51 that I sold. Changes direction quicker, stable, and maybe just as fast?! It's a blast to ride. Just gotta get it quieter!

-

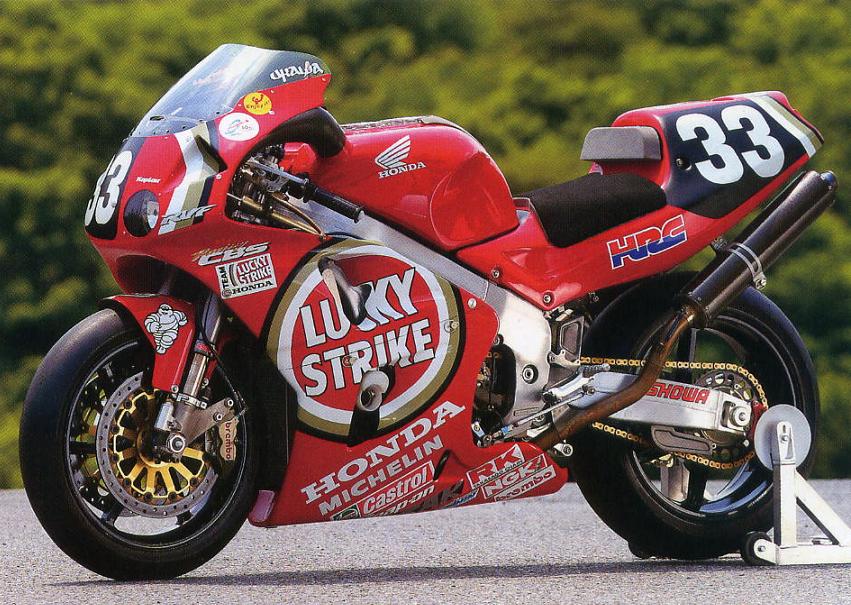

VFR to RC45 "ish" replica budget build

monstar replied to monstar's topic in Third and Fourth Generation VFR's

Does anyone know of a way to piggy back onto the ecm and be able to adjust ignition timing. I know they did something like this in the day with race bikes but that kinda analog stuff is really hard to track down. Just think there's a little to be had if you could map or just adjust the ignition curve somehow. That's how I stumbled on that youtube video above. -

VFR to RC45 "ish" replica budget build

monstar replied to monstar's topic in Third and Fourth Generation VFR's

Sorry if I'm answering my own question but I drew it on a pad of paper and I figured that basically nothing would happen until 1 full revolution of the crank. Then the firing order would be 1-2-3-4, firing every 90 degrees then a full 360 degrees and starts again. I think this guy is probably full of shit. I'm not sure if there is enough inertia to keep it running and how it would run like that. Anyone have any ideas? I would love to see if or how it runs. Someone give it a try! -

VFR to RC45 "ish" replica budget build

monstar replied to monstar's topic in Third and Fourth Generation VFR's

Well, I don't claim to know a whole lot about engine balance but I do know that with 1-3-2-4 firing order that 1&3 are 180 degrees apart and 2&4 the same. But between 3&2 there is 270 degrees and between 4&1 there is 90 degrees. So the rear bank fire close to each other then a longer pause and the front bank fire close to each other, then the rear bank comes up even closer and starts again. For those smarter than myself please correct me... What this does is change 1 from TDC of compression to TDC of exhaust stroke and likewise on 3. What would this mean as far as timing of the combustions? -

VFR to RC45 "ish" replica budget build

monstar replied to monstar's topic in Third and Fourth Generation VFR's

Still haven't gotten the time to clean up "grind" my welds or leak test them. Should be fairly labor intensive. I stumbled across something on youtube... Turning an RC36 into a "big bang" motor by flipping the rear cams 180 degrees. I know it's not a real big bang considering the it has to do with the 360 degree crank but I'm wondering if it's worth a try. Probably take a few minutes to do just to see. -

VFR to RC45 "ish" replica budget build

monstar replied to monstar's topic in Third and Fourth Generation VFR's

Well decided to weld the pipes. Let me tell you, I'm not a welder, far from it. Straight material I'm not too bad but tight radius stuff is harder than I expected. Looks like snot so no pics! Seriously, going to clean them up a little but honestly no one will see them anyway. As long as it holds up I'm satisfied. -

VFR to RC45 "ish" replica budget build

monstar replied to monstar's topic in Third and Fourth Generation VFR's

I just need to clean the metal before I spray the clear on. Right now the metal is rust free with some silicone spray but I'll be cleaning that off, applying some rust dissolver, wiping down with alchohol and baking in the oven to evaporate any hidden liquid and contaminants. As was suggested by dannoxyz, some brand of naval jelly will remove any hidden rust and prep the surface for the "paint" It's a little confusing, they have dissolver and neutralizer. The neutralizer is pretty much a primer that neutralizes the rust so it can be painted but it also contains polymers that I don't trust for high temp application. So I'll be treating with a dissolver and hope this clear coat sticks and can handle the heat. The reviews on this brand of clear coat are mixed so 50/50 chance it'll hold up when applied to bare metal. -

VFR to RC45 "ish" replica budget build

monstar replied to monstar's topic in Third and Fourth Generation VFR's

I was careful to not use at full strength and diluted in water bucket. The parts sticking out of the top are rusting as expected but I'm taking them out and wire wheeling them first, then scotch brite with silicone spray, then wipe down and applying silicone spray. I have a couple days until I get the clear coat so I'll see if any rust appears. I used to have naval jelly/aluminum jelly a long long time ago and have had no luck finding locally recently. May have to order some. -

VFR to RC45 "ish" replica budget build

monstar replied to monstar's topic in Third and Fourth Generation VFR's

Thanks for the advice. I totally understand mild steel will rust pretty quickly with moisture and heat cycles left untreated. I just wanted to give the high temp clear coat over bare metal a try. I'm just not a big fan of painted headers. If it works then I'm happy if not oh well... just not sure I have the patience to make SS primaries. Just want to be done with the exhaust and move on to other stuff. -

VFR to RC45 "ish" replica budget build

monstar replied to monstar's topic in Third and Fourth Generation VFR's

Although my primary pipes weren't junk yard rusted there is quite a bit of surface rust that's been cooked in. Tried wire wheeling on the bench grinder and some scotch bright wheels but it takes awhile and with just ok results. Trying a youtube trick with extra strength toilet bowl cleaner with Hcl acid to hopefully eat the majority of that away. I'm letting them soak in a bucket and will check every couple hours to see if there's progess. I'll most likely spend a couple hours doing most by hand but worth a try, right? -

VFR to RC45 "ish" replica budget build

monstar replied to monstar's topic in Third and Fourth Generation VFR's

Great! Well in that case, more photos. Just took the primaries off to clean the 20 years of black cooked on junk and hopefully brighten them up to match the stainless. I think I'm going to try the high temp clear. If it doesn't work out I'll either wrap the primaries or do a standard header paint. -

VFR to RC45 "ish" replica budget build

monstar replied to monstar's topic in Third and Fourth Generation VFR's

Sorry if I'm posting too much without major progress. Really had to stop myself from doing the finish welding until I get some angle material to weld onto the collector to support the whole system in place. 304 stainless has a tendency to distort when welded so want to make sure things are securely in place and straight/parallel/perpendicular. Finding the right settings to weld stainless has been a challenge. I went with .023 wire and have to run a lot or wire feed speed to keep up with the arc. Learning on the job! Good times 😕 meanwhile, altering my subframe for the a "real" rc45 tail section. Nothing else looked right and the link pipes and mufflers just need to be mated to those lines... -

VFR to RC45 "ish" replica budget build

monstar replied to monstar's topic in Third and Fourth Generation VFR's

Yeah I wanted to show off my trick chinese starter motor that leaks oil! I know everyone is jealous.