-

Posts

662 -

Joined

-

Last visited

-

Days Won

43

Content Type

Forums

Profiles

Gallery

Blogs

Downloads

Events

Everything posted by sfdownhill

-

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Cool beans, boOZZIE. Even simpler than the T-bolt clamp solution we were struggling with. -

Color code for bronze triple tree / risers

sfdownhill replied to 4corsa's topic in Eighth Generation VFR's

You’re welcome, but cross check that paint code before ordering/applying. I got it from another member here, but can’t find the exact source - I retrieved it from my notes. Here is a thread about powder coating using that color, which is almost exactly ‘Triple Bronze’ by Prismatic Powders: -

Color code for bronze triple tree / risers

sfdownhill replied to 4corsa's topic in Eighth Generation VFR's

Honda calls the 8 gen triple clamp/handlebar/wheel/clutch cover color Pyrite Brown Metallic YR-325M -

Under $30 Fuel Pump Repair/ CBR/VFR HYBRID BUILD

sfdownhill replied to MOTOPILOT's topic in Fifth Generation VFR's

Fuel pump first - it didn’t prime when the key was turned on with the run/stop switch in run position. The pump will prime even if the neutral switch, sidestand switch, clutch switch, and gearbox are not in order. Good job, Moto Pilot -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Hi MrSquiggle - between chuckles from enjoying your username, I can let you know we have a couple sets of 6 gen headers available from the last production run. I’ll PM you with more info. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

We have run our 5 gen and 6 gen test bikes without the heat shield behind the right rearset with no problems. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Looks great - love the grey with gold wheels, boOZZIE! I've fired one up without mufflers...sounds like an NHRA dragster... VFR rightside up [2] 07 29 16.mp4 -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Thanks Jay! It’s been awesome to learn so much about the machines our community loves and get a much-wanted component out to the guys. Wouldn’t have happened if you hadn’t been gracious enough to let me ride your wonderfully harmonized 5 gen with its headers and a fantastic tune by Mike Velasco. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Looking great Ducnut! -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Hi Maritan - got your PM and thanks for your interest. I’m writing from my phone just now, so I don’t have the dyno charts you requested, but will attach them to a PM when I get back to my laptop tonight. My subjective opinion is that the 8 gen benefits from the headers the most; more than 5 gen or 6 gen. This is due to the symbiosis between Honda redesigning the 8 gen’s cams to beef up the midrange and the headers’ increased breathing capacity. The resulting 16% increase in horsepower and torque at 7000rpm is a fun kick in the pants. In short, we are between production runs and sold out of 8 gen headers at the moment - sorry the timing is off for your project. We will be gathering orders for another production run as folks chime in for more headers. Wade the builder will do a production run when we have six committed orders, so the entry point is more easily reached than the previous minimum of fifteen orders. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

That is hilarious - it really does look like your 6 gen is peering curiously into the header box! -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Hey Flya - Vfr800witdawaffle is here...I just started a new PM and for recipient typed in vfr800wi and before I got to ‘waffle’ his username popped right up. Let me know if you have further difficulties tracking him down and I’ll see if I can get the two of you connected. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Update - we picked up the current batch of 5/6 gen headers earlier this week. Wade built 3 extra sets of 5/6 gen headers, so if anyone who already has headers and has installed them let a fellow VFR owner try their bike and it did for them what it did for me when I first rode a 5 gen with tuned Two Brothers headers, just point them over here. Yes, the previous sentence is a savage example of untethered run-on. Plus there are still 3 sets of 8 gen headers available. One of these 8 gen headers has been optimized for a front radiator conversion on a 5th or 6th gen. This one set of 5/6/8 gen headers has 2 additional O2 sensor bungs in OEM 5/6 gen locations. The seventeen headers for VFRD members were dropped off for passivating. Here they are on pallets, eagerly awaiting their refreshing nitric acid dip. Should be through the process in a week: Like the song says ‘And a little bit closer now’: Below are the J-pipes (rear cylinder primaries). The shorter J-pipes at the top of the photo are for cylinder #3 right rear, and the longer J-pipes at the bottom of the photo are for cylinder #1 left rear: -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

FYI Seb, six of the current production run of headers are intended for 6th gen VFRs. The sixth six gen’s sixth sick sheik etc etc -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Update - the current production run of headers has been completed! Wade is finishing off by adding the last few bungs, and we will head up to his shop to pick them up next Monday, then drop them off at the passivators. Thanks to everyone for their patience and support. Cogswell - thanks for the excellent weight comparison. Those of us who have installed the new headers have all been reveling in the throttle response and torque - here’s a quote from VFRD member Vfr800witdawaffle after he installed his 8 gen headers: ”So guys....I rode the bike today with the new headers and my lord!!! My bike is literally scary now. I feel like I have to hold onto the bars for dear life as this demon of a bike growls and propels me forward with the speed of a space X rocket. Traction control constantly kicks in if I try to gun it in first and second gear. Now I have trouble trying to accelerate in 1st and second. Also I don’t have the rapid bike module yet and it’s running super rich but It might have adjusted. When I first started the bike a whole bunch of I unburnt fuel was spraying out the headers for a little and then it calmed down. I’m also running it straight piped right now but I’m going to buy the module before I ride it again so I don’t mess the engine up. Thank you guys so much for being the ones that made this all happen!” Rock on Vfr800witdawaffle! -

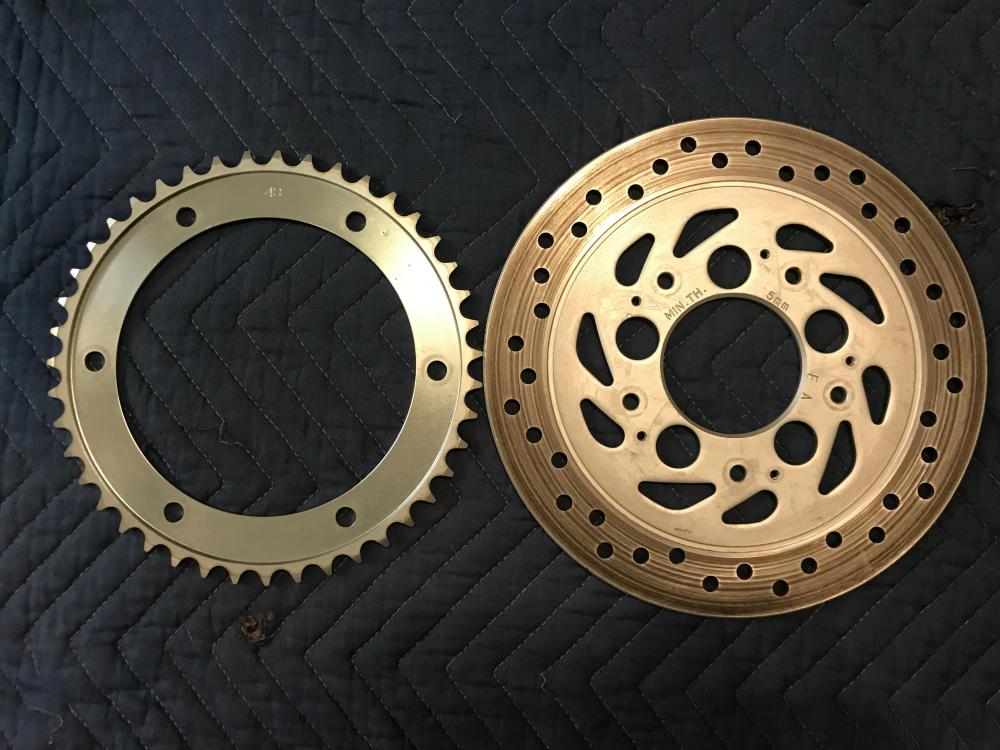

Complete kit to convert your 5th gen or 6th gen to 8th gen 10 spoke rear wheel. $575 plus shipping. Kit located in San Diego, California. Everything you need is included: - 8th gen rear wheel - straight and in excellent condition [Original OEM bronze finish] - Bolt-on 8th gen 5-bolt rear hub/axle assembly - OEM 8th gen rear driven sprocket, like new, 43 teeth, same as 5th gen and 6th gen - 5 OEM rear driven sprocket mounting bolts/nuts - OEM 8th gen rear brake rotor in excellent condition - One lug nut [To join the 4 lug nuts from your current wheel] - One brake rotor mounting bolt and nut [To join the 4 bolts/nuts from your current wheel] Here is an 8th gen wheel on a VFRD member's 6th gen [Schweet!]:

-

- 2

-

-

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Update - more 5th/6th gen headers will be available on the current production run. We connected with our fabricator Wade yesterday, and there is good news. He is building a few extra sets of headers for 5th/6th gen VFRs, so they are available if anyone was thinking about the next production run. The company Wade uses to do the mandrel bending of tubes bent a few extra sets, so Wade ordered the tubing merge assemblies and hardware needed to complete them. These are part of the current production run and will all have 3 bungs for O2 sensors, which means your options are open as far as 2 OEM O2 sensors, one autotune O2 sensor, one O2 sensor for dyno tuning, etc. Passivation - an acid bath for the headers [described in depth earlier in this thread] remains an option - $90 if you want it. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Hi rlindquist, There is a production run of headers for 5th gen and 6th gen being built now; those headers fill orders guys placed a couple months ago. From your VFRD profile, it appears that you have one of the beautiful 2007 red, white, and blue anniversary 6th gens - good choice of ride. To get a set of headers, place a deposit by making a $200 paypal transfer to the paypal account of vfrheaders@gmail.com. You'll be #2 on the next order we place [A production run achieves go status when we have orders for six or more headers] - Be sure to send the transfer 'SENDING TO A FRIEND' so paypal doesn't take out 5% - In the note section of the paypal transfer, include [1] your VFRD username [2] which generation of VFR you'll be putting the headers onto [3] your real name [if different than the name on your paypal account] [4] your shipping address [5] whether you want to have the headers passivated [Passivation is detailed in the PM we sent you]. PM us if you have any questions. Cheers! -

Power Commander V fix for 2000-2001 VFRs

sfdownhill replied to sfdownhill's topic in Fifth Generation VFR's

Sounds about right. -

Power Commander V fix for 2000-2001 VFRs

sfdownhill replied to sfdownhill's topic in Fifth Generation VFR's

That's very cool, Seb. PM sent -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Header production update - I spoke with Wade today, and learned that the current run of 15 sets of 5/6 gen headers will be completed in two weeks. He had a small delay related to the company that supplies tubing merge assemblies for our headers. Add one week for passivation, and we are 3 weeks from shipping. Thanks to everyone who been staying in touch about this production run. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

VFR members JZH and Duc2V4 prompted me to take Dusty's instructions out for a test spin. The info below is also posted on the 5th gen forum. The software is indeed intended to act as interface between a technician and a Dynojet dyno, but the program was free to download and came in a 123.88mb zip file. Power Core version 2.1.1 loaded easily onto my PC and includes four applications for operating and using a dyno for tuning. The Dyno Control app within the Power Core suite opened and under the support tab, the app was indeed ready to 'send data file', but I don't have a Power Commander V here to test the procedure. So the software and process are available, free, and viable, but we'll need someone with a 2000-2001 5th gen that has a PCV installed to verify that the patch file actually saves the day. -

Vfr 800 wheel in cbr 929 forks

sfdownhill replied to FrysianViffer's question in Modification Questions

I can't be certain about CBR929RR front rotors, but can tell you that CBR900RR front rotors have the same bolt pattern and offset as the 5th and 6th gen VFRs. But the 900 used a 16" front wheel, where the 929 used a 17" front. Hope this helps. -

Power Commander V fix for 2000-2001 VFRs

sfdownhill replied to sfdownhill's topic in Fifth Generation VFR's

That's a good question, Captain. I don't think I'd mess with a working PCV system like yours unless there is a guaranteed way to restore the PCV's firmware/software to its original version without the patch. If the patch screwed up your VFR's operation and your PCV couldn't be restored, you be stuck with a Dynojet brick equipped with a fuel injection harness. Regarding the 'not very clean' idle, have you tried synching the starter valves? I have not yet done this on my 2001, and I don't know for sure whether the starter valves are related to idle - just throwing it out there. -

Power Commander V fix for 2000-2001 VFRs

sfdownhill replied to sfdownhill's topic in Fifth Generation VFR's

Good question JZH and good observation Duc2V4. You guys prompted me to take Dusty's instructions out for a test spin. The software is indeed intended to act as interface between a technician and a Dynojet dyno, but the program was free to download and came in a 123.88mb zip file. Power Core version 2.1.1 loaded easily onto my PC and includes four applications for operating and using a dyno for tuning. The Dyno Control app within the Power Core suite opened and under the support tab, the app was indeed ready to 'send data file', but I don't have a Power Commander V here to test the procedure. So the software and process are available, free, and viable, but we'll need someone with a 2000-2001 5th gen that has a PCV installed to verify that the patch file actually saves the day.

(320x240).jpg.38b069b1b132757a379ac125171ccd8d.jpg)

(320x240).jpg.a398222f1094a0e5fed956955576316c.jpg)

(320x240).jpg.8c48bac91f0dc5a6632f8a1fe8755195.jpg)

(240x320).jpg.86c4f0090a938de7a75f76fd2ab1e5d9.jpg)

(320x240).jpg.3cc26a1299244f2c22dd796cd692f42b.jpg)