-

Posts

2,127 -

Joined

-

Last visited

-

Days Won

88

Content Type

Forums

Profiles

Gallery

Blogs

Downloads

Events

Everything posted by Terry

-

Buy LEDs that have the emitters located in the same place as the stock bulbs; that way the beam pattern replicates the halogens and does not cause any excessive dazzle. You are looking for a vertical stagger between the front lowbeam and the rear highbeam, and also a shroud under the lowbeam. If the emitters are anywhere else, do not buy them! All of those eBay links are garbage, you should be looking for something more like this:https://www.ebay.com/itm/176702874520?_skw=H4+LED&itmmeta=01JWSBH9HAT1QPPVWKJCEQSYC4&hash=item29244fe398:g:-zkAAOSwLP1nRFvJ&itmprp=enc%3AAQAKAAAAwFkggFvd1GGDu0w3yXCmi1esvc7hjWo2Z3Hyd38NYSaqdIjC7t7KiaDmEndqlgZOg8Z3l53vWgQQKyRznpecRAxrgrHAEQsjBcFM2UC1HRQAY5X5SQI72A8rAaGW%2BSpOVnkn4TbqBUnml1R1DpH7IZyCUgjFb2ZiR%2Fgkz9r86Cl5viRzlTxf1WARyoKTu%2Fnh0ZHi1souscXva1lh50W3TAckvlFrXEcTbAeJkSxbGZ%2Bq1Q%2BhjAGtzWobqRagjQb1Zg%3D%3D|tkp%3ABlBMUIaZxavmZQ The 45/45 stock bulbs have a unique layout of the 3 locating tangs on the bulb base; the more common 60/55 base has the lower tangs in a different position that won't fit directly into the socket on the VFR reflector shell. You can buy adaptor rings but it is simplest just to snip off the tangs on the new bulb; the top tang remains and "clocks" the bulb correctly and will provide a secure mount. LEDs consume less power than halogen bulbs and also produce less overall heat so are unlikely to stress any part of the wiring loom more than halogens. Try putting a 100/80W halogen bulb there and see how much the plastic power connector enjoys the extra heat!

-

Those tiny holes are in every master cylinder I've opened up. They are called compensation ports and allow excess pressure to bleed out of the master e.g. so as the fluid heats up and expands the brakes (or clutch) don't start binding (or in the case of the clutch, slipping). Ports like this are why you need to flush the brakes often and push all the cruddy stuff out of a bleeder. The linked brakes on the VFR, CBR11, ST1300 etc are just more sensitive to poor maintenance.

-

Paging @Captain 80s I haven't done this myself but believe you will be looking for a CBR600F2 wheel (17 x 3.5 rim).

- 1 reply

-

- 1

-

-

For your viewing pleasure...here's one I disassembled earlier. Note the very small port circled in red. The mesh screen on the blank side can be gently worked up out of it's groove with a pin.

-

The SMC is just another master cylinder, so not difficult to strip and clean. The unique part is a small blue "cartridge" that contains a screen and one-way ball valve, that is accessible once you pull the fluid hoses off. The cartridge has a very tiny port in addition to the ball and spring, but these can be pulled apart and cleaned just don't lose the ball! Rear brake lock-ups can be caused by the SMC piston corroding and jamming, or just from blockages in the tiny ports.

-

Three 10A fuses with continuity to battery ground

Terry replied to WorldFamousWino's topic in Fifth Generation VFR's

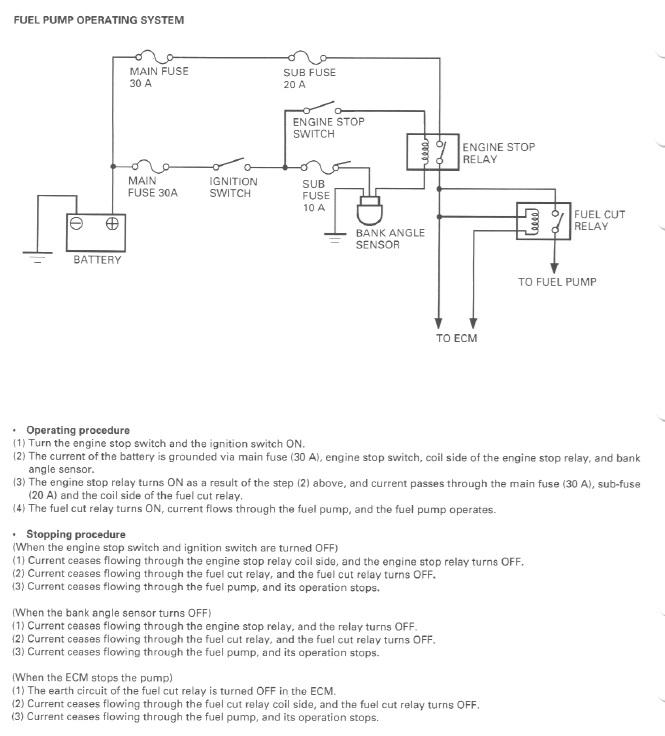

I guess this depends how you look at things. A circuit usually starts at the +ve terminal of the battery, through the ignition switch and then through a fuse (or fuses) and then through a device (e.g. taillight bulb) and then to ground (-ve). So I would expect continuity to ground from the fuse for any device that is normally "on", but not for things that are normally switched "off". Has someone put the battery in backwards??? Is that even possible??? Not sure if the attached diagram will be of help with your questions around the BAS and the FCR. -

If the front end has been lowered (e.g. fork tubes slid up through the triples) then that raises the rear wheel further when on the stand and makes it harder to lever onto the centrestand. If you have the stock bars, the retaining circlip on the fork tubes should be in contact with the bar tops which will be in hard contact with the triple clamp. A lower-than-standard profile rear tyre would also do this but I'm not sure whether they exist (stock is 180/55, maybe a 190/50 would drop the rear profile by a few mm).

-

A while back I found a really good explanation of RRs from a Superhawk forum member called Tweety. I made this into a document for future reference as his explanation is outstanding (and even better when you know English is not his native tongue...) MOSFET Regulator.docx

-

You may need to switch over to conventional hadlebars; there are kits available that either replace the whole upper triple clamp or simply add a couple of bar clamps in place of the clip-ons. Have a look for Hurricane handlebars from Webike Japan, or Trickbitz on eBay.

-

Here's a link to the manual. Happy reading. https://www.vfrdiscussion.com/index.php?/files/file/150-service-manual-6th-gen-2002-vtec-with-bookmarks-new-cover-ocr/&do=download Sounds like you need to trace from the battery positive forwards and find out why you are having power (or not) in unexpected places. You can pull a fuse at a time and see which one makes the instrument lights go out. There is a constant 12v feed to the dash but only for the clock. 6th gens do have occasional issues with the common earth block which is in the nose of the bike, usually orange or blue, these can get corroded and cause strange behaviour.

-

In my experience the HH pads from EBC can be louder when applied than others; mine certainly make an audible buzz when applied.

-

A 5/8" master would bring the master/slave area ratio right back to stock. The 6th gen stock operates 5 pistons up front (unlike the 5th gen which does 4).

-

First ride of the season and the side of the road.

Terry replied to trmoyer's topic in Fifth Generation VFR's

That sounds like a broken battery, not just flat. Maybe an internal break. Even a "flat" battery should show some voltage. -

My 99 runs at a right around 180F on the freeway which is the thermostat opening point, which tells me there is excess radiator cooling capacity at that point. I would be rechecking your thermostat as it sounds like it may be jammed. My easy thermostat test (no disassembly needed!) is to start the cold engine and let it warm at a standstill and keep a hand on the radiator. If the thermostat is working the radiator stays cold until you reach 176-odd which is when it should start to open and dump hot coolant out to the radiator, which you feel as a sudden jump in temperature. If the radiator slowly heats up from when you start the bike, the thermostat is jammed open. If the radiator doesn't get hot around 176 then it may be jammed closed.

-

As you can see from my Avatar image, I also have a 5th gen and have to say it appears to pull just as hard right through the rev range with it's boring 16v system. VTEC does seem like a bit of a gimmick but I quite like the character that it gives the 6th gen. I am old enough to have ridden 2-strokes in the 80's and it is (a little) reminiscent of that...My inner conspiracy theorist thinks VTEC was introduced to distract from the switch to chain drive for the cams, which I am sure was solely for noise/cost reasons.

-

Having just had my VTEC bits apart the underside of the bucket is formed into shim shape as part of the casting so the net effect must be quite similar to the CB400, just with one less part. Maybe they were concerned about the shim becoming dislodged? The VTEC spring does hold the VTEC sliding pin hard up into the bucket so I'm not sure how it could ever come out but someone at Honda must have been concerned. The CB400 design would certainly make a shim change a cheap proposition as the VTEC buckets are US$27 each and I needed 6...

-

I am pretty sure that you could weld the sliding parts under the buckets into the latched position so the VTEC valves are always engaged. It would be irreversible however. The ECM is only sending out the signal to the VTEC solenoid to send oil pressure to the VTEC area so I can't see that would matter at all. The fueling might not be too good without some correction.

-

That's a good tip to use nuts. Once you have the parts in your hand you realise that any suitable piece of hard material would do the job as the spring that is compressed is not stiff and the bucket holds it all together. I also ordered 4 x 2.72, along with 2 x 2.76, and I moved a couple of the 2.86 buckets that were already there. I will keep Impex in mind, thanks.

-

Bad grounds are a standard issue with the 5th gen. There is an orange common earth block taped into the loom below the seat left side; a small rectangular block that you can feel under all the tape. Not uncommon for these to get some corrosion and cause all sorts of weird behaviour. Regarding the relays (and sorry if this teaching you to suck eggs). A relay is a switch that is activated by current; you have a coil that will show continuity between the terminals always, and then two other terminals that will only show continuity when the coil is energised by pautting 12v through the coil terminals. You should be able to hear/feel a click when the coil is actuated.

-

Have you looked for the Bridgestone BT45 or BT46? They are available in stock sizes and work great. I stayed with stock sizes on my recent '86, but back in the day used a 140/70 without clearance issues and even (foolishly) a 160/60. The 90 refers to % of width so where a 130/80 would be 104mm high, the 130/90 would be 117mm so your tyre will be 13mm higher. The only place that would matter is between the tyre and the cross-member at the front of the swingarm.

-

Sounds a bit odd; the fuel pump should run for a few seconds and then stop, but will run continually when the engine is running. Maybe the relay is bypassed somehow or is energised constantly through the ignition? The fuel cut relay and fuel pump function tests are in the manual around page 5-48.

-

Sudden fire after months of riding.

Terry replied to ChessmasterHex's question in Modification Questions

The stator puts out over 50V AC and the regulator rectifier should bring that back to 13-14V DC. If you saw 18V before the excitement then yes I would say your RR is borked and you need a new one (maybe a better one this time). Looks like a lucky catch! Hope your battery survived as well, maybe look for signs of heat/bulging. -

1992 750 fuel starvation

Terry replied to flyintwowheeler's topic in Third and Fourth Generation VFR's

It is a diaphragm pump in which the internals just shuttle back and forth in response to the points/coils. There is no way for the pump to run backwards. Your symptoms are classic fuel supply problems so I would not be looking anywhere except the tank outlet, petcock and fuel pump. If the fuel pump is cycling rapidly then it is being starved of fuel flow from the tank. Normal behaviour is to cycle rapidly until fuel is flowing and putting a bit of load on which slows the clicking, and then when the carbs fill and the float valves shut, the pump stalls out until the fuel level drops in the float bowls. I'm not sure what you've checked so far but a kinked fuel hose that gets hot and squishy, blocked tank air vent, blocked fuel outlet, failing vacuum petcock would be possibilities. -

Bike wont start (without some help) after injector/ fpr swap.

Terry replied to NorthernV4's question in Modification Questions

The MAP sensor is located on the back edge of the airbox, and has a skinny vacuum tube plugged in from below. Very easy to miss plugging it back in... -

If you have a car and jumper cables I would suggest trying to start with these connected; that way you can eliminate the battery as a source.