-

Posts

3,395 -

Joined

-

Last visited

-

Days Won

61

Content Type

Forums

Profiles

Gallery

Blogs

Downloads

Events

Posts posted by Skids

-

-

How do you plan a twisty route on them? Google Maps always gives me the quickest route plus 2 alternatives.

-

You can get plenty of led bulbs that dont dazzle.

60/55 is standard UK spec. Is your spec different?

-

4 hours ago, MBrane said:

I'm happy with my EBCs.

Same here.

-

23 hours ago, FromMaine said:

Yes, it's a tax disc. IIRC, the practice was in effect when I purchased the bike, but discontinued shortly after.

Skids: Never really noticed that they were on the left side TBH. Had to go through my pics to shake the cobwebs.

Now that I am riding on the right side of the road again. Think I'll leave it there.🙂

It might be right, but it's not correct. 😉

-

2

2

-

-

4 hours ago, Captain 80s said:

That's a "Tax disc", right? Which they phased out before you left?

Correct.

My 01 800 came with one and is still mounted.

Though they were supposed to be mounted on the LHS so they could be seen by the policeman walking along the pavement.

-

1

1

-

-

On 3/3/2025 at 3:00 PM, Sweeper said:

I loved my last 6th gen and never planned to sell it. When my daughter started riding, I got her a CB500x and then started riding it myself on occasion. After riding it in the mountains, I realized that lighter and more comfortable was a good thing. I was in my early sixties and had no plans to two up or do long days on the open road so I started looking. The CB was a great little bike for carving up tight mountain roads but only had 48hp. I ended up with a Tiger660 that has the same chassis specs as a early CB500X but 79hp and hard bags that don't require an ugly mount. Best of both worlds now. The Tiger will run circles around a VFR in the mountains, can tour comfortably, and is even fun on the track. I know of seven or more VFR owners who have switched to the Tiger660. If you need a little more, there is the new Tiger800 sport. No experience with it yet.

I've test ridden both the 660 and the 800 when I was considering swapping out the Crossrunner. The 660 lacked the punch of the VFR and whilst the 800 was a great ride, it costs a lot and I'm still a little doubtful of the build quality of a bike that would have to be ridden through English winters. Neither of them are a replacement for the VFR1200 though.

I decided to keep the Crossrunner as my commuter (170 mile round trip) until I retire in Jan 26 as it is simply brilliant. It's a proper VFR but with a really easy riding position which I need at my age.

This has brought me to my VFR1200F. I love this bike. I've spent a lot on making it a better, fun ride and able to tour too but the riding position takes it toll and so I've purchased a VFR1200X Crosstourer. I know the hp is well down on the F but everything else works for me. I've only managed to take her out for a short check ride (bought unseen, 5 yrs old with less than 900 miles on the clock and a full Honda annual service history and I had 2 weeks to hand her back so she needed a test ride) and I believe the bike will give me what I want, Shaft-drive, bigger fuel tank, perfect riding position, big luggage and that motor. She's stuck at the back of the garage atm and for various reasons, wont be coming out until my new double garage is built and I can move the CR and CT in along with the F and Fi-1 coming over from my son's garage.

I wouldn't mind a test on the new V2 Duke but I'm not a big fan of all the tech (more to go wrong?) and it's very, very expensive so unlikely to really be a contender. The CT was a bargain imo and I can't wait to get her sorted and regularly ridden.

-

3

3

-

-

2 hours ago, Morados said:

That is a nice looking machine!

Are you gonna replace your VFR800X?

No, i won't need a commuter so she goes.

-

-

I've done 2 braided replacements, 5th and 6th gen and it's by far the biggest improvement in braking feel. Step by step, it's not that difficult. I did it, twice, so it can't be that hard.

-

1

1

-

-

Can't agree more. I've had one fitted to my Crossrunner for a few years and one on the 1200. The 1200 sounds even better. 😜

-

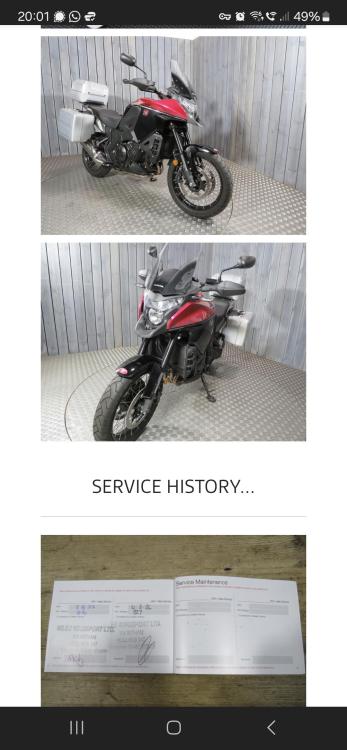

A VFR1200X Crosstourer arrives 7 Feb. Whilst I love my 1200F, she's is increasingly harder to ride for long periods as I get older. The X has the benefit of an upright seating position, a larger fuel tank along with the beautiful engine, albeit less power.

She's a 2020 model with only 832 miles from new. Dealer stamps for all Annual Services and full Honda luggage.

Lots to check when she arrives; fluids etc but really hoping the weather improves soon so we can enjoy this beauty!

-

6

6

-

-

8 hours ago, V4 Rosso said:

Squished them and they take their original shape again. Pretty good stuff made by Knox Armour with a hard outer shell and dense foam inner padding

Knox make very good kit. I have a couple of pairs of their armoured jeans, a vented jacket and a couple of pairs of gloves. Nice fit, well made and quality D30 armour.

-

1

1

-

-

No recalls for my 1200 on Honda UK website

https://www.honda.co.uk/motorcycles/owners/safety/recalls-updates.html

-

Personally, I can't wait to see the factory power unleashed.

-

2

2

-

1

1

-

1

1

-

-

Uses the Honda motor car logo instead of the Honda motorcycle logo. Doesn't mean it's a made up piece but.....

-

I changed my 08 brake lines for Galfer braided and I really liked the end result. Combined with a caliper overhaul, it will ensure your life-saving braking system is operating to near maximum.

Changed out my 01 lines too, excellent results.

Do it

-

1

1

-

-

Welcome and please let us see some photos when you get the bike.

-

If you are looking for a VFR800X Service Manual, they are available for free in the downloads section.

https://www.vfrdiscussion.com/index.php?/files/file/271-2014-vfr800f2015-vfr800x-service-manual/

-

1

1

-

-

5 hours ago, mello dude said:

Awesome RC51! A bike thats on my bike lust list!

Me too, but they are soooooooo expensive.

-

1

1

-

-

1 hour ago, Mohawk said:

Re undoing left axle nut, not having looked at an 8th gen in close up, I assume its staked like the 5/6th gens. Have you unstaked it ? Try a little penetrating fluid on the outer nut to axle thread seam, leave it soak for a couple of days.

Thanks, already done both of those. Will make another attempt this weekend.

-

21 hours ago, Mohawk said:

As noted above by JZH the carrier has a ridge level with the axle bearing. There are some simple tricks to avoid snagging any debris. On a stock swingarm always loosen the chain tension first by rotating the carrier clockwise, thus pushing any debris away from the carrier before moving it anti-clockwise to set the chain tension. If it will not move freely then you probably have existing debris jammed into the carrier &/or corrosion.

Strip & clean to fix it.

To avoid future issues, you can either glue some fine gauze mesh over the square holes on the insides by the shock to stop debris entering the swingarm &/or mice as per Dutchy's post. Or do same inside the end of the swingarm carrier holder. Also ensure the swingarm drain hole on the bottom just in front of the carrier holder is not blocked.

If you use your bike in all weathers then the carrier/holder interface can corrode. To avoid this do NOT use lube, but coat inside of holder & outside of carrier with ACF50 or your chosen water displacement anti corrosion treatment. Allow to dry fully before assembly. If you ride in very wet conditions you can use a wipe of silicone grease around the carrier to holder joint to further reduce the ingress of water to the joint. I would also fit water caps to the square holes near the shock or seal them to prevent water ingress through those openings.

As soon as I am able to release the 46mm nut on the hub, I shall do that.

Good tip re moving carrier the opposite way first.

-

On 10/20/2024 at 7:40 PM, Presson said:

Hi Skids, at the risk of being captain obvious, you said you were going to have to strip down and clean the mating surfaces. I'm assuming you haven't done that yet if you are still having to use hammer for chain adjust?

Given our climate (heaven knows it's been like monsoon season this last 4 weeks) and winter salt, I'd strongly recommend a bit of grease on the mating surfaces. I'm thinking copperslip but others might suggest a different type.

I'm trying to think up a simple means of covering the forward holes on the swingarm to avoid the build of of grit that JZH showed in his photo. I'll post if I find a working solution

Hi m8, no. I tried. I managed to get a lever arm approx 1.5metres long with the 46mm socket on the end.....and it wouldn't budge!

-

8 hours ago, bmart said:

37k miles is nothing. Ensure all maint is up to date and check all systems...then ride it like you stole it.

What he said.

-

1

1

-

-

1 hour ago, JZH said:

This picture, of one of my old bikes, shows what happens over time when grit builds up in the end of the swing arm (it enters through the big openings next to the shock).

As you can see, the bearing carrier has a casting feature that can catch on any grit which protrudes above the level of the machined part of the swing arm when you attempt to rotate the bearing carrier for chain adjustment.

Once the pinch bolt is loose, there is nothing which should require hammer force to rotate the carrier. (You can also gently open the swing arm carrier opening even more by inserting a large, flat blade screwdriver into the split.)

I don't see any real need for lube on these parts.

Ciao,

JZH

Thanks m8.

I do still have to hammer it to adjust the chain.

.jpg.c3506398578f31098cdbd7042c58baf7.thumb.jpg.67cea31c209584c96506c943ad6f59ce.jpg)

Carpuride system?

in Sixth Generation VFR's

Posted

Do these devices require their own sim card for Google Maps to operate or is Maps linked from your phone?