NateRC36

Members-

Posts

32 -

Joined

-

Last visited

Profile Information

-

Location

united kingdom

-

In My Garage:

VFR 750 L 1994, 30,000miles.

CB 500R 1994, 92,000miles

Bandit 1200 (in bits)

NateRC36's Achievements

-

I look forward to seeing your results once the priming issues is sorted. Would your cell fit behind the number plate? if so it could be mounted vertically which would solve the priming issues your having. Nate EDIT - get ubuntu linux - the latest version runs silky smooth and makes old laptops seem new again (although I am running windows 7 on this laptop it has no support for the graphics chipset so streaming video/watching dvds is a no go)

-

If your bikes injection does it have an O2 sensor some where in the intake? If so the extra oxygen coming from the cell will be picked up by this and the system will add more fuel to compensate which will then increase the revs. This will also lead to a lower MPG which is why you have to run the system a little leaner to compensate for this. The best option is to add a MAP sensor on a timer switch (or manual switch) that you can turn on when the revs rise (so this will give you a cell warm up period, similar to using a choke). Nate

-

Yes trapped air is a problem with this cell which is why I will run it on the pump for a while and rotate it until no more air bubbles up through the header tank. I just need to decide on what pump to use - I've found drill powered pumps and an wondering if I could adapt that to fit on the sprocket cover of my cb500 but I'll probably look at chemical processing industry for a low volume/low power pump. I like how you have added an individual feed to each plate, mine is drilled in such a way that the electrolyte circulates and flows over all the surfaces which I think wouldn't be quite as efficient as your cell. One major fault with my layout is that if it's left to generate without the pump switched on pockets of gas will build up in small areas which would further reduce efficiency. I really look forward to seeing your results! Nate

-

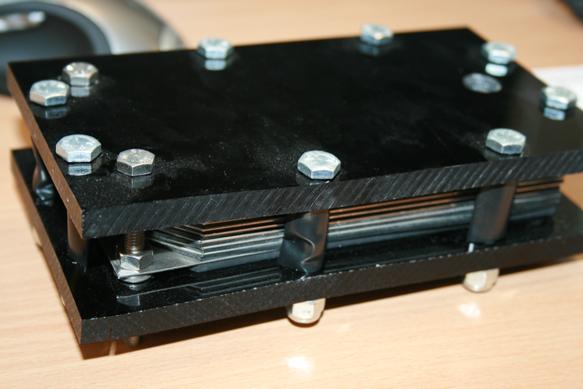

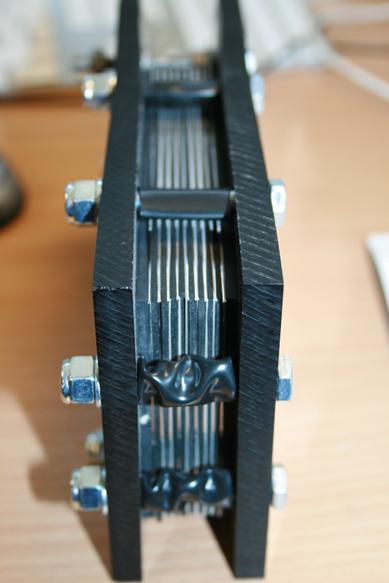

JES_VFR, Here's my cell. Let me know if you'd like pictures from different angles. I have to replace one of the nylon plates as I over-tightened the anode terminal causing it to fracture, it's just cosmetic and it's still water tight - it just looks crap! Nate

-

oh BTW, I have a HNC in Engineering, originally being an Instrumentation engineer by trade...

-

Since when did I mention gravity? I was referring to the laws that supposedly applied to the electrolysis methods used in this example and other HHO production systems... I'm gonna take the high road and not insult you! Nate :cheerleader:

-

The root cause is how Joe Public has been "conditioned" by an education system controlled by a governing body funded by oil companies.... TBH no one person can do anything about it - but people's eyes are opening thanks to the internet and the immense wealth of information available to anyone with the motivation to use it.

-

I have to say you guys will be proven wrong! These so called "laws" are stipulated by a man, who is himself not infallible. The laws are so dated, take the laws of Thermodynamics for example - they were made before the introduction of high oscilation square tooth wave forms, low power ICs didn't exist.... the second law of thermodynamics was established in the 1820's (when man thought airtravel was impossible) so do you really think that they still stand true today with the amount of advancements made in other areas? :beatdeadhorse: Hmmm, either that or I've taken too many blue pills...

-

Well said! I'd try and help out with my understanding of it all but I've been through all that before.. the proof really is in the pudding with this one. Regarding conspiracy theories.. take the Diesel engine for example, that was originally designed to run on crop oil grown by farmers to power their machinery - the inventor was murdered and the engine was reborn years lator to run on a by product of oil refining! The oil companies are very powerful and they dictate almost every aspect of our lives - just think of all the products that come from oil, it's mind boggling to say the least - then imagine our modern way of living without those products... Nate :biggrin:

-

Cheers for the update/info. Here's the link for the DC-DC converter http://gb.mouser.com/ProductDetail/Artesyn-Technologies/SMT40C-12SADJJ/?qs=wFvjjzoUshL%252bTAp46cm1Cg== The benefits of using one is that you can cut the number of plates you use and have access to a higher amperage than say with a neutral stacked plated arrangement - as that relies on neutrals to lower the voltage between plates yet it's still limited by the supply current - where as stepping down the voltage greatly increases the amount of current available at the load side of the DC-DC converter 10amp @ 12v or 40amps @ 3v both equate to 120 watts consumption. Regards to the metal, conditioning it thoroughly before use is a necessity - I carried out 5 x 6 hour cycles - each time using a fresh KOH electrolyte until there was no residue floating on the surface. I'm not 100% sure about using KOH in the engine as it can be carried in the vapour which would cause heavy damage to the valve edges. Here's another link you may be interested in http://peswiki.com/index.php/OS:Moray_King:Closed-Loop_Water_Fuel_Cell From what I've studied to get an engine to run exclusively on HHO you need to carry out a number of internal modifications : - ignition needs to be past TDC, Hydrogen ignites at a significantly faster rate than petrol, if it were to be ignited at the same point as petrol it would cause bad pinking/knocking... basically f***ing the piston/rods. - Eliminate any waste spark that may occur (unless timing is taken off of the cam gear) since the ignition advancing will bring it to the intake cycle igniting the intake (kablammo!) - stainless exhaust (lots of water vapour - a by product of HHO combustion) - stainless steel valves - possibly ceramic coat the bores to ensure longevity (long term exposure to hydrogen causes the metals to turn brittle) You can get really deep into this - stuff like tuned resonance circuits, saltwater radio wave combustion, joes cell, shim-stock coil cells, bacterial hydrogen, additives that react with water to produce hho, etc etc. I no longer own my RC36 - partexed her for the CB500 solely to save money on fuel/consumables and to make servicing easier (plus I've been promised a new motorcycle pending a payrise at work - maybe a Datona 675 or a Thruxton... not too sure yet!)

-

Okay Nate, I have to ask a couple of questions. 1. How many cells are in your dry cell design? 2. What material are you using for your plates? 3. What are you using for electrolyte? 4. What is the surface area of your plates and how large are your gaskets? 5. You are using a bubbler/drier as a backflash arrestor, right?? I won't go too far into detail but I'll answer the above.. 1. 9 plates 2. high molybdenum content stainless. 3. still not decided on this. 4. Plates are 150mm x 75mm, plate gap is 1.25mm. I did work out the active surface area but don't have the notes to hand. 5. I've been using a standard in-line flashback arrestor as the reservoir acts as the bubbler and it has a pop-off lid to prevent pressure build up. What pump are you using to circulate the electrolyte? I have experimented with one from a water cooled PC block although it isn't suited to the harsh chemicals involved. Btw - using low voltage means I can configure the plates +-+-+-+-+ amperage and voltage is inversly proportional, so dropping the voltage will mean I have a higher number of amps to play with 20amps @ 3v is equal (no including losses) to 5amps @ 12v I look forward to seeing your results and I'd like to add I'm not on here to debate, just to offer support as this is a subject I'm very much interested in. I've been distracted from this project and have been following Orbo as well as working on a replication of this... http://www.fdp.nu/cack_movie/janPCack.asp I have an interest in magnetics and have been playing with a basic magnetic resonance circuit using a ferrite barium magnet core and the sound output from my PC as a signal generator... I wish I could afford an oscilloscope! I believe refining the combustion engine is flogging a dead horse and clean, solid state electric gen is the way forward... I will post pics of the cell/space under the CB when I get the time to. Nate

-

BTW forgot to add that's a very neat install you have there and the community a peswiki.com would love to see the dyno results and if there's any improvement on mileage/performance. Nate

-

Hi, I also have a dry-cell configuration, I was planning to put into my RC36 and use a DC-DC converter to drop the voltage down to 2.6v (the nominal voltage for electrolysis) which would enable me to boost the output up to 20amps without straining the charging system too much (works out a little over 40watts consumption). To cut a long story short I decided not to install it on my bike as I was stuck for finding a space to install the header tank. I now have a CB500 which has quite a roomy boot under the seat, in which I will install my dry cell and then mount the tank either on the back rack or directly above the cell. Does your cell run on brute force electrolysis? I've put together a basic PWM circuit back when I was bench testing a few ideas but I'm not entirely convinced it's worth installing it - especially if I use a DC converter to raise the amps. PS - to everyone interested in learning about HHO production visit http://peswiki.com/index.php/Directory:Electrolysis Cheers Nate

-

They're good quality, I brought a standard exit set of headers for my 94 RC36 and they fit well, no leaks, and improved engine running (but that was mostly due to the pin holes in my last exhaust. 24,000 miles later and no complaints, finish has held up against crap British weather (just slight spotting on headers and the odd stone chip). There's probably higher quality kit out there but as a direct oem-like replacement these are definitely the best value. Cheers Nate :fing02:

-

Hey guys, Sorry for the late reply on this. I did end up buying standard exit s/s exhaust headers as I felt the centre stand was too useful to ditch! My bike still has the standard plastics as I ended up replacing the clutch basket and plates and all wheel bearings as well as servicing every serviceable component on the bike - I still have money left over with which I'll be ordering the acewell speedo, lower clip-ons and a hornet headlamp. Once the front has been "cafed" I'll be looking for a flat board cafe seat (preferably with a removable hump for when the lady wants to come for a ride) and I'll be sorted! Thanks for all your help and advice, very much appreciated, when I get the parts and start work I will post pics up on here. With regards to the left exit headers from Sandie's spares they said they will sell the headers separate from the end can and were willing to allow a viewing to see there quality before purchase! Nate :beer: