-

Posts

22,516 -

Joined

-

Last visited

-

Days Won

103

Content Type

Forums

Profiles

Gallery

Blogs

Downloads

Events

Posts posted by SEBSPEED

-

-

Download the photobucket fix for your browser (google it)

-

15 hours ago, squirrelman said:

A spark is a spark, why spend the money, why bother to change from OEM ? no advantage i can see.

any more HV? don't think so.

any more HV? don't think so.

someone, please, why is this any better ??

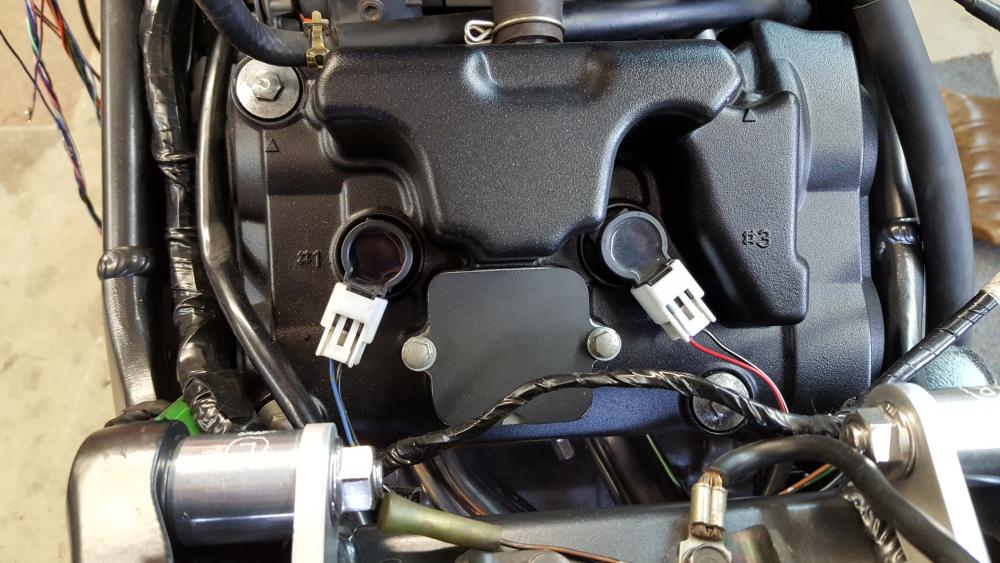

Lighter weight, smaller packaging, potentially better spark. I'll leave it to someone else to prove that. although common sense seems to dictate that as fact when you look at both designs.

I switched for the first 2 reasons. One more would be future-proofing... the '08 CBR coils are 10yrs newer than the oldest 5th gen coils which are now 20...

All that said, I've got a set of '99 coils for sale. LOL

-

11 hours ago, KevCarver said:

Seb, did you have to trim the boot like Stray did (above)?

I didn't trim anything. I pushed them in very firnly, felt & heard the plug thread engage. Felt the grommet at the top engaging the bore at the top too. They do not wiggle or move at all. It takes some good effort to pull them out, and when you do, you can feel most of the resistance is from the bottom end engagement with the spark plug top.

-

-

Hi SEBSPEED,

Thank you for your donation of 50.00 USD. We look forward to improving the forums with your donation.

Thanks VFRDiscussion

-

On 11/6/2016 at 12:30 AM, CasualSwede said:

Hey Seb, a few questions, maybe others could find them useful.

When you cut the wiring tunnel at the front of the tank, did it actually intrude into the tank, or was it just a lip/stamping that you were cutting?

And for your rear brake line routing, any thought process on drilling locations in the swingarm for pass-throughs?

Thanks!

Sorry for the late response folks...

The cut did penetrate the tank cavity. I actually sliced the tank and rolled the edge over into the tank, then welded it shut.

On the swingarm - I routed the line through one of the larger forward openings toward the rear, and out the existing drain hole which I opened to a larger size to allow the banjo fitting to pass through.

On 7/28/2017 at 11:00 AM, Millertime19d said:Good morning. I absolutely love this build, along with the lighter blue build which is why that is my primary choice for a final color, or a gunmetal grey. Regardless, my question is what has everyone had the best luck with in regards to front end swaps, to include upside down forks and clamps? I have the possibility to get my hands on a blown motor and stripped 929 parts bike. Just curious what everyone recommends. By the way, '96 750F for reference

Hello & thanks, the 929 is a good choice, if i'm not too late to say so.

-

So run the 3 spoke till the SP1 or SP2 pops up. They do come up, you have to be vigilant because the CBR owners like to run them as GP replica wheels also.

-

That money would be much better spent on fitting a RC51 SP1 wheel. It looks just like the VFR front (which btw does not "match" either, since front are 6 spoke and rears are 5 for some reason??). The SP1 wheel is the only 6 spoke front that will accept the 330mm discs. It should fit the 929/954 forks directly.

I fitted a SP2 5 spoke wheel in 06 'blade forks to my 1996, to match my 98 5 spoke rear wheel.

-

I don't remember all your specs, but if your compression has been bumped up it will be slower to turn over. Being cold doesnt help. Could try a car battery (car not running!)

I bet it's tight because it's fresh. That first fire should be real satisfying!

-

1

1

-

-

Which ones did you end up using Robbie?

-

1

1

-

-

Sidestand, neutral, and bank angle switches functional and accounted for? Pump primed numerous times before cranking to ensure full system pressure? Checked for spark? Assuming correct motor assembly, those are the easy things.

Could check timing and the cam pulse generator inside the clutch cover (red 2p connector).

Or give'r a squirt of ether and cross your fingers? ;)

-

If they were 6th gen...

-

Really cool to see some progress here! Happy for you and excited to see some dyno results!

-

I started a new thread for each year I hosted the ride.

I've been really busy trying to work my day job and get something else off the ground, I have not ridden a motorcycle all season. :(

-

How's the job hunt Leon? You still on hiatus?

-

You can make anything fit, if you have the tools and talent to do so. The only tail that bolts on directly, is the original...

Good luck with it, and have fun!

-

Details on the slider pins please? Just finished rebuilding 4 of those calipers, could use some!

-

Looks good, can't wait to see it out in the wild! It is the first known crash survivor! :D

-

Those are just remnants from the casting process, carry on

-

Bike is FOR SALE, to fund the next project! Message me if interested!

-

Looks nice.

Man, step away from VFRD for awhile and this is going on. Late to the party but nicely done Seb! Haven't been over to CustomStreetFighters lately either where I'm sure you had a thread.

Thanks Kel

-

On 4/10/2016 at 1:12 AM, HighSideNZ said:

Fatigue on the aluminium for road use and panniers.

I'd feel much more confident with steel than ally in that situation.

As a sole reason, this is a bit silly. Thousands of airframes built of simple formed sheet endure far more abuse than your bike will see in 20 lifetimes - if engineered properly, your subframe could do the same.

Also, if you are capable of tig welding steel, then it is highly likely you can also learn to weld titanium. You can weld Ti outside a chamber, if that was your concern.

-

1

1

-

-

Still no diy on this one? I need to weld something on my bike!

Sent fra min SM-N910F via Tapatalk

Sorry, I don't sell individual parts. More than happy to modify a cover for you though! International shipping is no problem!

-

1

1

-

-

I'm the dude...

...and The Dude abides.

Seb,

I couldn't help but notice the post counter under your avatar:

...so I've been meaning to ask:

1. Is that a real post count for you, or was there some weird server restore back in the day that resulted in a large archive of posts being assigned to you?

2. If genuine, how does one accumulate more than 23,000 posts?

I think of myself as an active member of the board, but at my current post rate of approximately one post per week it would take me [...does some math...] 450 years to rack up that many posts. I don't think I'm going to get there. Or, if I resolved to achieve that milestone sooner, it would take better than six posts every single day for ten straight years without interruption.

Is there a story there?

It's real... let's just say there was a time when I was less distracted by tools and machinery... and a wife... and family... lol Being around the site for 10+ years helps too.

So I might have done a thing......

in OTHER Motorcycle Talk (non vfr)

Posted

Core Moto is good stuff, use them for all my custom projects. Love the dished head banjos they supply. They are fast too.