-

Posts

28 -

Joined

-

Last visited

Profile Information

-

Location

Bowie, MD

-

In My Garage:

1998 VFR800

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

garcenw's Achievements

-

Kickstand clearance with Knight Design lowering pegs on 5th Gen?

garcenw replied to garcenw's topic in Fifth Generation VFR's

I bought and installed a pair of the Knight Design pegs. I got the ones MaxSwell shows in the picture above except I choose the silver colored ones. My comments: 1) You notice more vibrations at certain RPMS, but it was not annoying for the 2 or 3 miles I traveled for a quick test. 2) I would say the drop is less than the 1-3/8" KD claims. I didn't have proper measuring equipment at home, but I jerry-rigged something with wooden blocks and index cards. I got about 1-1/8" difference in the center of the pegs. Keep in mind that the rubber on the OEM peg compresses some, so the effective drop will be a little less. Nonetheless, you can feel a noticeable difference between OEM and the KD pegs. 3) Space gets crowded on the shifter side. I tried rotating the shifter down 1 spline, but that was too much. I went back to my original location and it is a hair high, but still better than one spline down. I'll try it as is for a bit and if it doesn't work out, I'll bend the shifter a bit. I ended up bending the tang down on the kickstand to give me the room to move my foot around. This made the kickstand harder to deploy (see 4 below). 4) With the tang bent, it's harder to deploy the kickstand. I'm using size 45 Alpinestars SMX-6 V2 Drystar boots and they are pretty bulky. When I stick my heel in between the shifter and foot peg to deploy the kickstand, my heel rubs against both the foot peg and the shift lever. If I do what MaxSwell says and look down, it's not issue, but if I don't, I sometimes accidentally shift the transmission from N to 1st. If you have narrow boots or a smaller foot, this might not be an issue, but if you are using boots with any sort of spine or lateral support hinge or one with wide soles or a large heal cup, this will be something to watch out for. I suspect it would be less of an issue with some of the narrower boots that I have. 5) I took out the locknut on the brake adjustment to lower the pedal as much as possible. The issue is that the threads on the adjustment stud hit the lever before the hex bottoms. I backed off half a turn, but the pedal wasn't low enough. I then cut three threads off with a Dremmel and was then able to bottom the face of the hex, but it still wasn’t enough. It is tolerable, but not ideal. I'm going to try it like this, but I'm pretty sure I will end up bending the lever as JoelF did above. -

Kickstand clearance with Knight Design lowering pegs on 5th Gen?

garcenw replied to garcenw's topic in Fifth Generation VFR's

I took a pic today to better describe my concern. In the picture below, which is with the stock setup, I took my boot and placed it on the peg with the shift pad of the boot just under the shift lever rubber. There is a slight upward torque on the boot to ensure it is snug against the shift lever. If you zoom in on the scale in the pic, you can see there is approximately 7/8" between the top of the tang and the sole of the boot. Now if you lower the peg 1-3/8" as Knight Design claims and you lower the shift lever a similar amount, it stands to reason that your boot can hit the side stand tang. Now I realize that you may not necessarily lower the shift lever the same amount as the pegs, but tang contact with the boot still seems possible, perhaps likely. What my picture does not capture is what actually happens dynamically, i.e. in actual usage. It is possible one's foot isn't that far inboard when shifting. If contact does occur there are things you can do, such as bend the tang, trim the tang, or add a spacer to the stand's stowed position travel stop, but I'm just wondering what the actual users are experiencing in regards to this. -

Kickstand clearance with Knight Design lowering pegs on 5th Gen?

garcenw replied to garcenw's topic in Fifth Generation VFR's

MaxSwell, With the pegs lowered, I would naturally rotate the shift lever on the spline to lower it and this was part of my concern, i.e. my foot would be lower both front and rear when upshifting. Obviously, if needed, I can add a spacer to the portion of the side stand the travel stop hits as long as cornering clearance isn't compromised. I'm just wondering if the tang interfering with ones foot has been an issue for those using the KD pegs. You mentioned lowering blocks, but the pic above doesn't have the blocks. It instead has the KD pegs. Did you mean the 2000 you used to own had KD pegs and you noticed no interference with the tang? -

The space above the fill line is called vapor space. It is there to allow for thermal expansion of fuel when the temperature of the fuel gets above the fuel's temperature when it was stored in your gas station's underground tanks. The vapor space is designed to test your patience, but with enough persistence you can fill the tank to the point where you cover the vent. Most of the time, nothing happens when you do this as you will immediately start consuming fuel upon leaving the gas station. But say you live really close to your gas station (e.g. on the same block) and parked your bike at home in the sun on a hot day right after filling: you might see some fuel leak out of the tank vent. Fuel on the ground adds risk, so manufacturers add vapor space to mitigate that risk. If you want to fill per Honda's design intent, fill to the bottom of the fuel inlet. I'm not familiar with the 6th gen, but it should have a conical opening where the rubber gasket seals against. Fill to the bottom of that when storing the bike. When immediately riding for some time after filling, you can fill her to the brim.

-

I'm contemplating ordering the Knight Design lowering pegs for my 1998 VFR800. For those that have tried the KD lowering pegs on their 1998 - 2001 VFR800, I have a question: Is there an issue with kickstand tang clearance when you reach your foot under the shift lever to upshift? I ask, because, visually, it seems like the area of the foot under the arch may hit the tang when you reach under the shift lever. By "tang", I mean the protrusion you use to deploy the side stand. Thanks. - Walt

-

I finally got around to doing the work to check/replace my thermostat in my 1998 VFR800. Removing the throttle body assembly required lots of lube and lots of mechanical persuasion. The thermostat was failed open (about 1/4" at room temperature). I tested the new thermostat prior to installing to make sure it worked per the spec and it did (it opened in the mid to high 170's F). With the new thermostat, it warms up a lot faster. I went out Sunday night and maintained 70 mph on US50 between Bowie, MD and Annapolis, MD. Ambient temperature was 39F. My dash gauge varied between 168F and 169 F when I held the aforementioned steady state speed, so I'm matching what "MadScientist" and "MaxSwell" reported. I guess the bypass hose to the radiator is just enough flow to allow some measurable cooling to take place which is why the gauge temperature is less than thermostat temperature (assuming the dash gauge is somewhat accurate).

- 55 replies

-

- 1

-

-

- temperature

- thermostat

-

(and 1 more)

Tagged with:

-

KevCarver, Did you happen to test the old and new thermostats in a pot of hot water before installing the new thermostat?

- 55 replies

-

- temperature

- thermostat

-

(and 1 more)

Tagged with:

-

I lived in Roseau for 4 years when I was an engineer for Polaris. It seems that northern MN has more than their fair share of hooved forest rats.

- 55 replies

-

- 1

-

-

- temperature

- thermostat

-

(and 1 more)

Tagged with:

-

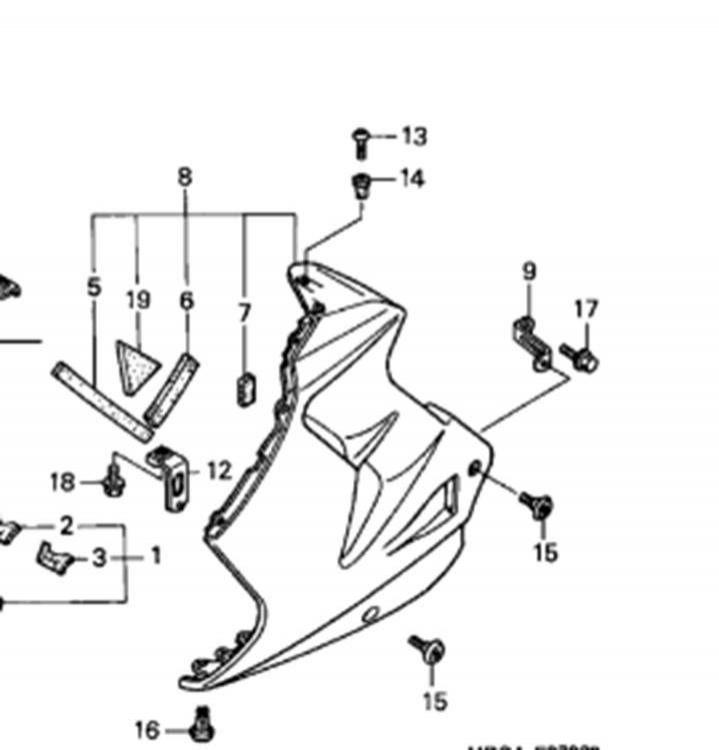

The lower left cowl I ordered arrived yesterday. I haven’t had a chance to do a color comparison in bright sunlight, but I did a color comparison last night in the dark with an LED flashlight and this afternoon in very overcast conditions. The paint match was very good under those conditions. The real difference is in “patina”. The old paint on the bike has fine swirl marks from I guess washing and the new one is pearly smooth. You could tell which plastic was new and which plastic wasn’t. The VFR decal was on the fairing as were foam parts 5, 6, and 7 (see pic below). Part 19 was not on the fairing. Part 19 doesn't even show up in the parts list on the various websites I checked - it just shows up in the fiche picture. I was not impressed with Bike Bandit’s packaging. The box was soft without support and had buckled at various points. The leading front corner of the cowl was poking thru a tear in the box, but still covered by the bag it shipped in. About a 1 mm x 10 mm section of paint got scraped off. It isn’t really an issue as that is the tab that goes into the nose piece. The lowest trailing corner of the fairing (what would be by the kickstand) had paint got worn off, but were talking about 1 mm x 1mm area that you can’t easily see. I suspect that got rubbed off in shipping as that corner was pushing up against the inside wall of the box as there was no foam packing to brace the fairing in the box. All they used was brown paper stuffed haphazardly in the box. As soft as the box was, I’m surprised the cowl didn’t arrived cracked. I checked the part over very carefully and found no cracks. I suggest anyone ordering plastic body parts do the same. Other than that, I’m happy.

-

sealing washer for water pump/coolant drain bolt?

garcenw replied to bud's topic in Fifth Generation VFR's

If I recall a new washer isn't called for in the factory maintenance manual, but the part number is 90463-ML7-000. -

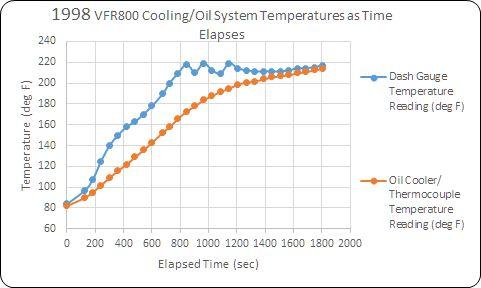

I did a similar idle test, but this time, I put the thermocouple in the center of the oil cooler. Ambient temperature on the dash gauge was 82 F, while my thermocouple indicted 84 F. Let's call it 83 F. My results are plotted below. As you can see, at least while idling from a cold start, oil cooler temperature asymptotically approaches water temperature and the oil is slower to warm up than the coolant. I'm not sure if this would be the case while running on the road. I was expecting warmer temperatures in the oil with all the fluid shearing going on. The up and down cycling of the coolant temperatures after ~800 seconds is due to the fan cycling on and off.

- 55 replies

-

- 1

-

-

- temperature

- thermostat

-

(and 1 more)

Tagged with:

-

KevCarver, Sorry, I should clarify what is meant by "steady state" for the non-engineers here. The temperature indicated was steady state which means I was running long enough and in relatively stable conditions so that the temperature leveled off. In the particular run you asked about, I did about 20 minutes of city driving before hitting a flat and non-curved section of limited access highway. Temperatures got as high as 206 F (briefly) in that city driving. Once on the highway, I maintained about an indicated 65 mph (true speed would be a bit less) until the temperature leveled off at 165 F (bouncing back and forth between 165 and 166, but spending more time at 165). I repeated the test going the opposite direction on said highway on my way back and temperature also leveled off at 165 F.

- 55 replies

-

- temperature

- thermostat

-

(and 1 more)

Tagged with:

-

RVFR, Folks get worked up over the temps over 200 F, but I don't see those as an issue, unless the temps get past the warning temp level on the gauge. Most cars run around 195 to 210 with nominal loads. I wouldn't worry much about temps in the 200 - 235 F range. My concern is on the low end of the temperature scale once warmed up. Are steady state temps below thermostat temps normal? Normally not, but unlike some other vehicles, the VFR800 bypass goes to the radiator. That bypass is not insignificant in size, so there is the potential the some heat dissipation always occurs at the radiators even when the thermostat is closed. I'm trying to establish what are the normal steady state temperatures are on cool days before I decide to pull my thermostat out and test it. The temperatures I'm seeing (a little below thermostat opening temperature) are in the gray area if one assumes the bypass allows some cooling to occur and also accounts for the acceptable error in the head temperature sensor (which is a thermistor). - Walt

- 55 replies

-

- 1

-

-

- temperature

- thermostat

-

(and 1 more)

Tagged with:

-

sfdownhill, KevCarver, Mathematical symmetry can be a tricky subject. - Walt

- 55 replies

-

- temperature

- thermostat

-

(and 1 more)

Tagged with:

-

sfdownhill, I don't know the spec for the Mustang, but car thermostats typically open in the 190 F to 205 F range. The thermostat is likely working fine, it's just the wrong thermostat. The thermostat is the killer because of all the hassle to get to it. You can change the thermostat and correct the fan first. BTW, turning the fan 180 degrees doesn't change the blade pitch direction and thus the flow direction is the same. All it does is reduce fan efficiency. The motor polarity musts be reversed to change flow direction. Those two changes will, more than likely, fix your elevated temperatures. If not, then you can get the radiators flushed. - Walt

- 55 replies

-

- temperature

- thermostat

-

(and 1 more)

Tagged with: