-

Posts

662 -

Joined

-

Last visited

-

Days Won

43

Content Type

Forums

Profiles

Gallery

Blogs

Downloads

Events

Everything posted by sfdownhill

-

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

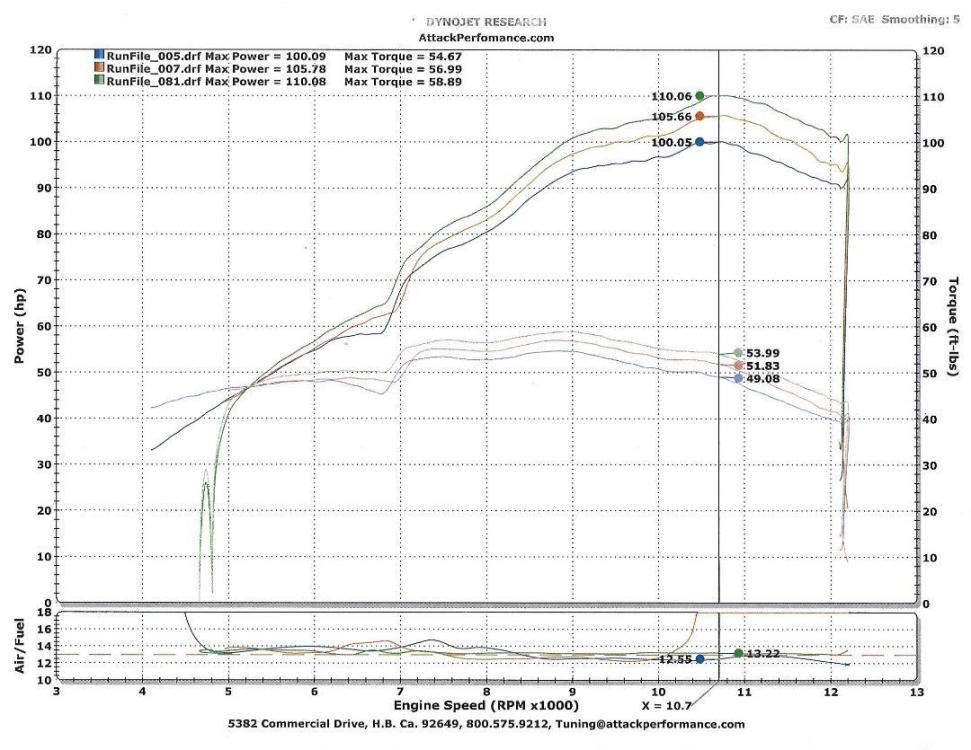

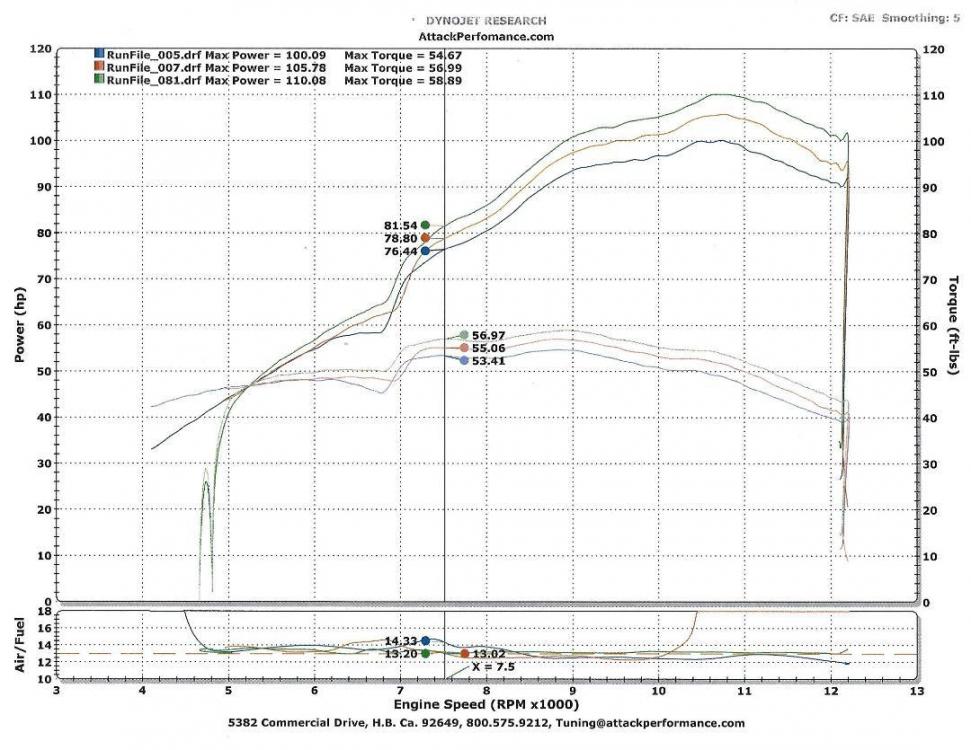

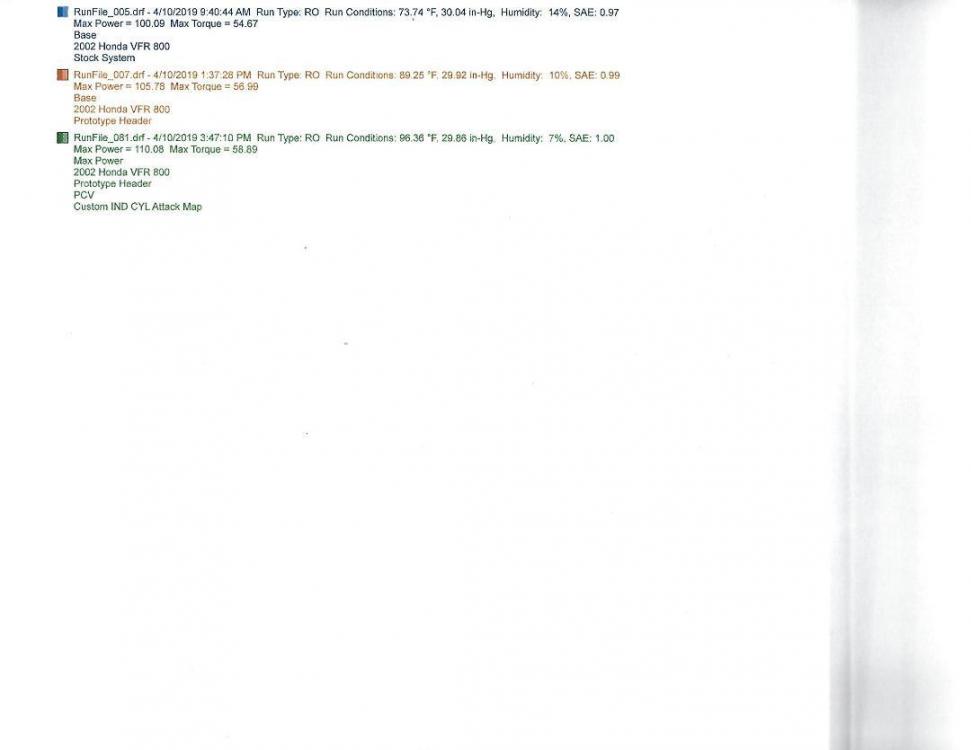

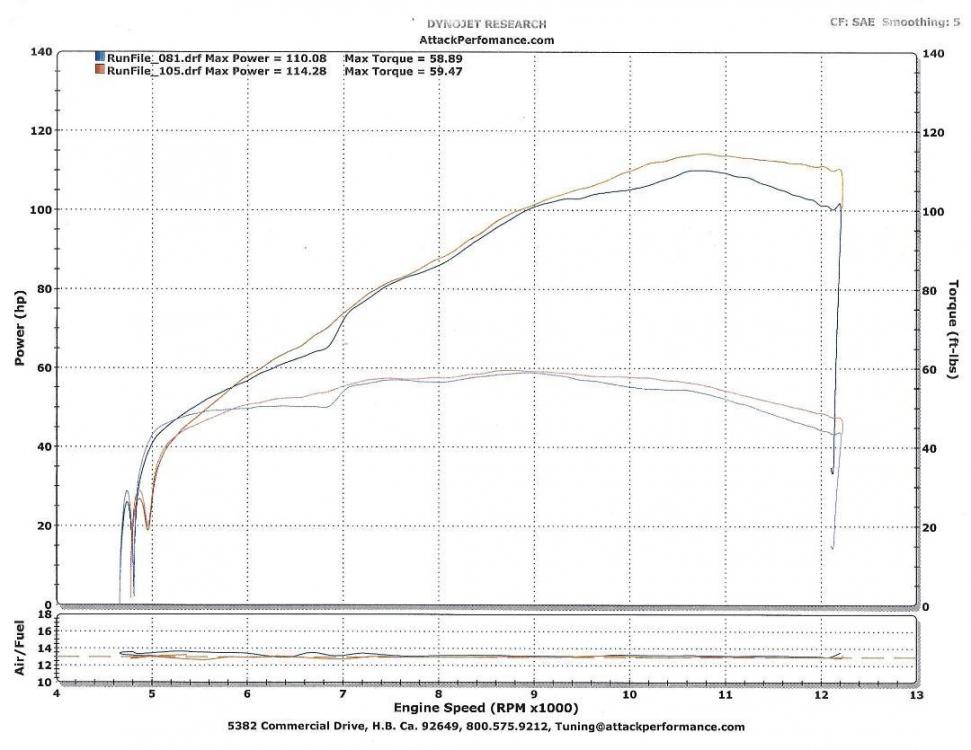

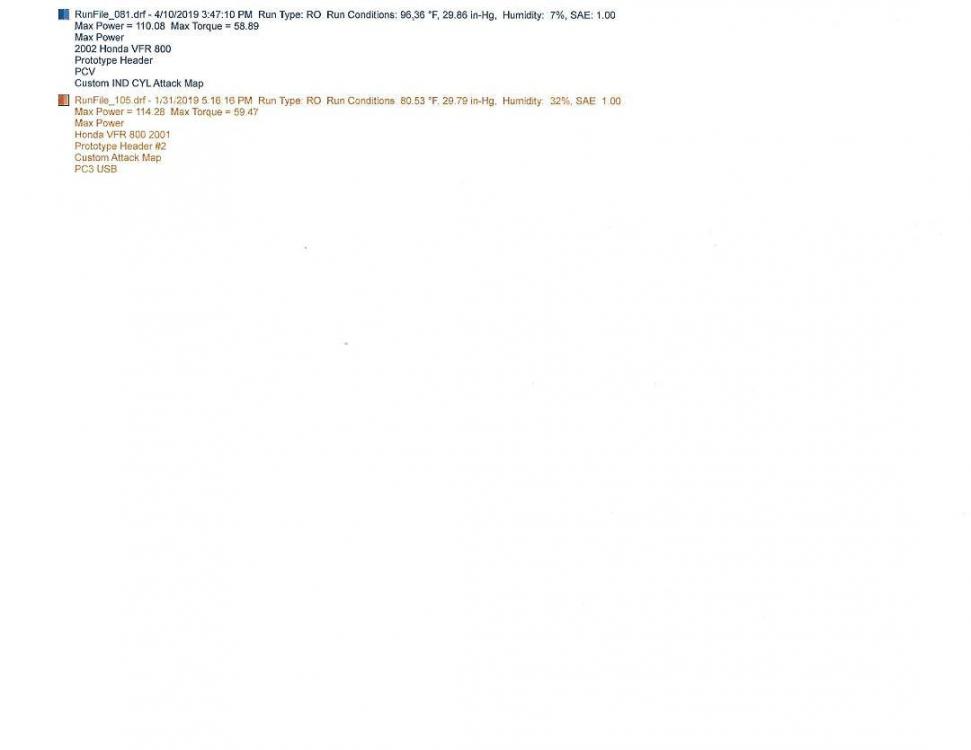

DYNODAY II : V4 GOES VTECH!! This is VFRD member Hammerdrill's 6 gen. It has all these components in black: forks, rotor carriers, frame, OEM mufflers, swingarm, drive hub, footpegs, radiators, etc. In the middle it has Sebspeed's clutch cover, up top it has an 8 gen cockpit [bars and triple clamps] and deeply red R157 bodywork. All this black and gold pops with contrasting with pearl white wheels. I can't get enough of this bike. And it's not just a pretty face, it runs and handles great, as it is suspended by a full DMr suspension that Jamie built for Hammerdrill's weight and riding style, and has a Power Commander V smoothing out the fueling. So raises the eternal question - what next mod would benefit this motorcycle and keep us out of trouble for at least a short while? Answer: Put it on the dyno! Get a baseline, then put new headers on it and tune the living heck out of it. So we did. Wednesday April 10, we showed up at Attack Performance prepared. We had test fit the headers two weeks prior, and brought all the accoutrements we'd need to put the bike in Jozef's capable hands for baseline and tune. I've made myself late here, so will slam up dyno charts and try to explain my way out of the ticket later. [Who can figure out the lean spike in AFR between 10k and 10.5k rpm?] 6 gen baseline with zero map in PCV compared to middle graph w new headers and zero map in PCV, compared to top graph after full tune: Here is the same comparison with a midrange reference line: Conditions on the day [All runs occurred same day]: Comparison of tuned 6 gen to tuned 5 gen, both tuned with the new headers: 6 gen vs 5 gen conditions: -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

A 6 gen fitment of the 8 gen exhaust is a great idea. The only obstacle is near-term availability of a 6 gen for this test. I'd be happy to take a 6 gen with me when I take the 8 gen up for final pre-dyno fitment, but the two 6 gens we have easy access to are Hammerdrill's, which is now totally dialed and dyno tuned with the new headers, and Duc2V4's, which is his 'daily driver' - it gets him to work projects all around socal and he can't afford for it to have a few days of downtime. We'd be open to any other 6 gen loaner on which to test fit the 8 gen headers. But we are deep in 5 gens, with four on hand. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Yessir - more angle on the next batch fersher. It's a bit frustrating because I have OEM 6 gen headers and measrued their bung locations carefully. I put the OEM 6 gen headers in Wade's hands and specified that the two bung locations on the new headers' secondaries match the OEM. I'm in Texas [Yes for COTA motogp!] so won't be able to check the 6 gen headers until Monday night, but dang, I swear these new header's bung locations match OEM. For the sake of those of us who don't yet know: What problems are caused by water collected on and around an O2 sensor? -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Last night's snoozefest continued: 5/6 gen production headers went to the passivators this week and will be ready to pick up end of next week. DucV4 and I have arranged to have a box-building and packing party as soon as we get the headers back, so shipping will take place April 22. 8 gen headers are under construction - Wade says we will have a working example ready for final fitment and the dyno at the end of next week. The first objective on the 8 gen headers was to build a mockup set of headers from which he will build a jig [fixture] like the one he built around the original Two Brothers headers. This process was easier on the 8 gen than it was with the TBR, because the TBR were rare and sacrosanct - under no circumstances were they to be damaged. To build this mockup, Wade was free to cut, tack weld, sew, test fit, stitch back together, add length, change bends, etc. At his shop last Friday, he was making lots of sparks, loud metallic screeching sounds, and generating the smell of very hot metal all day [After disassembling the 8 gen, I hung around and kept busy with test fitting 5/6 gen headers to confirm bung placements]. Item #1 on his list was installing the upper rear primaries, and right off the bat, spacing didn't look great; they were too far apart from each other, and they ran into hard parts of the 8 gen. Part of this turned out to be the thick OEM crush gaskets that I neglected to remove - the gaskets were pushing the new primaries out of alignment. Most of the problem was caused by two other fitment/engineering conflicts we ran into. First, the 8 gen rear primaries are of much smaller diameter tubing and cross over each other before turning downward to where they merge. The left rear primary of the new headers, with larger diameter tubing and no crossover, runs into the inner heat shield - this is the curved sheet metal piece that resides between the left rear primary and the shock absorber. On the 8 gen fitment bike, we temporarily removed this piece. Second, the brake hose from the ABS controller to the rear caliper comes into contact with the new headers. We temporarily removed a bolt that holds two hard brake line fittings together so we could scoot the hose over - without disconnecting - and install the new rear primaries. Refresher note: 8 gen OEM left and right rear primaries merge with each other, and 8 gen OEM left and right front primaries merge with each other. 5/6 gen OEM [and new performance headers] left front and left rear primaries merge with each other, 5/6 gen OEM [and new performance headers] right rear and right front primaries merge with each other. Note the gussets Wade added here [and other places visible in other photos] to maintain spacing during assembly. Radiators off to start on the interesting part: crafting the front primaries. Here you can see the 'starter tubes' Wade made and installed into the front exhaust ports. Note visegrips holding a spacer in place: The collector exit was somewhat less trouble. IMPORTANT NOTE: the 8 gen single OEM bung and O2 sensor are 12mm, not the 18mm fittings we've found with 5/6 gens and Bosch wideband sensors. Here is a nut tacked into the OEM bung location as placeholder: Everything was starting to look good, until we installed the fitment Staintune slipon and found it too far to the left, which meant the front end of the headers was misaligned. Think of the vertical sections of the rear primaries [at the slip joints] as the center of a pivot; if the rear of the the header assembly is too far to the left - and it was - the front section of the assembly needs to be cut and reformed to bring the rear into alignment. Wade doesn't get phased by adjustments like this, he just chops off the offending appendage and gets busy making his mockup correct. In this case, cutting off the front pirimaries and realigning them correctly pivoted the assembly around the rear primaries' slip joints and the whole assembly came into front-center-rear alignment. Somehow this pipe looks good on any bike. That's it for this update. I'll do 6 gen dyno day results in the next post. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Then how are we supposed to get the inside of the pipes clean? -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

I apologize for the delay in posting updates - Duc2 V4 has been responsibly reminding me that header related things are happening and those who have purchased headers or placed deposits have a right to know. The photos and brief details in this post will be supplemented with further information once I get to a peaceful place with a slower pace - the airport tomorrow. Shipping - Duc2V4 and I discovered that the USPS Retail Ground shipping rates we quoted are only available in person in a US Post Office, after standing in line and filling out forms by hand. Luckily, Duc got busy with his corporate Fedex account and his careful cross-checking found that he can ship Fedex for about the same as the bargain basement price of USPS+insurance. With Fedex, specifying the package value establishes a coverage amount, so the headers shipped Fedex will be covered. First shipped headers received - VFRD member carlgustav received prototype 2 headers today and we traded texts on fitment to his 6 gen [Prototype 2 was constructed and tested in January] . His install is looking good, but will have to wait until after a family celebration this weekend. 8 gen dyno day rescheduled - I made a mistake in thinking that the objective of last Friday's visit to Wade's shop was to produce a working 8 gen prototype. I was wrong - the actual objective was to fabricate a tacked-together 8 gen header from which Wade could build a jig, as he did with the original Two Brothers headers. Temporary tack welds to hold assembly together: I am nodding off, so will pick this up again tomorrow. 5/6 gen production headers are paid for and have been picked up - we visited Wade last Friday, counted up the 22 headers with various bung configurations, paid for them, and loaded them up into the rig to bring then home: Second objective last Friday was check bung placement. Wade correctly observed that whether they were right or wrong, all the bungs were already done. Nevertheless, I test fit a 3-bung set of headers on our 5 gen fitment bike and all 3 bungs ended up their proper places. Here is the rear bung placement [Please pardon the accumulated rust and crud on the chain and center stand - this bike's rehab is off in the future a bit]: And here are the front two bungs: -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

I weighed it at a Postal Annex shop - 7.3kg / 15.9 lbs -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Hi MBrane - if wade sticks to his commitment to hand over completed headers next Thursday, we can set up a time for you to pick up yours. If the 5/8 gen muffler fitment exercise hasn't yet taken place, bring your pipes, and we'll see how things line up. This is prototype 2 packed and ready to ship to VFRD member carlgustav in Alabama. Once again I am confronted by my poor before-and-during photo-taking habits. That significant hunk of cardboard is 36x16x16" to allow minimum 2" on every side of the headers for protective packing material. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

If all goes according to plan, the new 8 gen headers will be the same as the new 5/6 gen headers from the collector exit all the way forward [including the rear primaries] until the front sections of the two front primaries. Ken, yesterday Wade assigned us homework that pertains to your question about 6 gen fitment : to help foresee any fitment issues with the collector exit of the new headers for 8 gen, we are going to attempt to fit OEM mufflers and aftermarket slipons from both 8 gen and 5 gen to both of those bikes - gonna throw a multi-pipe mini-swapmeet party. Four mufflers, two bikes, no rules, best fit takes all. Even if the muffler hanger mount holes/brackets are in different locations, we will get a rough idea of whether collector exit length, angle, and position line up between the two motorcycles. If they line up as expected [Or should I say as hoped?], we can relax a tiny bit. Fitment of 6 gen dual high mount mufflers can be extrapolated from the results of the 8-5 gen muffler exchange matrix because we had to cut 5/8" off the new 5/6 gen header's collector exit before the 6 gen OEM mufflers fit correctly on a 6 gen motorcycle. After the cut, OEM 6 gen mufflers fit perfectly. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

... -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

First off, Duc2V4 and I are very grateful to all the purchasers of headers. Thank you all for responding so promptly to our accounting details, shipping estimates, and requests for payment. Second item - yesterday morning I got a text from Wade saying he wouldn't be able to deliver the headers this week. His text had a congenial tone and even joked about the "Many many many many varieties" ['Varieties" meaning different combinations of collector exit length and bung options]. We exchanged a few more texts - I was attempting to determine the exact cause of this 3rd [4th?] delay, but failed to gain any insight. Duc2V4 and I discussed what the best way of dealing with this last of several delays would be. We decided that today [Yesterday, Thursday March 28] I would load up the 8 gen test bike and drive out to Wade's shop - two hours each way - to pop in unannounced and get to the bottom of the delays. We elected to take the 8 gen because Wade had indicated that he had down time, and if the down time was real, we could make progress on the 8 gen prototype headers. At the shop, I found that all the headers in this production run have been completed, but none of them have had any bungs installed - lack of bungs is the cause of the delay [ See photos below]. This delay is my responsibility because three weeks ago, when exchanging information about bungs and bung locations with Wade, I asked him to use 3/4" tall bungs instead of the 1/2" bungs he has in stock. I specified taller bungs because I had just examined and measured OEM bungs on 6 gen headers; they are 3/4" tall. Also, we used tall bungs on prototype 1 to minimize intrusion of O2 sensors into the gas path, and the results were very positive. 3/4" tall bungs [Like OEM] are not common, so Wade contracted a local CNC shop to make stainless steel bungs to order for no additional cost. The CNC-equipped supplier of bungs has failed to deliver bungs. Wade and I charted an alternate course of action to obtain bungs if his local source failed to deliver by Monday. More importantly, we made a hard date of next Thursday April 4 for all the headers to be completed, paid for, and picked up. I have taken that day off work and will procure a vehicle large enough to transport 22+ headers. Your age can be guessed by which parlor or board game you think the photo below resembles. If you say 'Pick Up Stix' you are probably in your 60s. If you say 'Jenga', you are probably in your 40s, maybe late 30s. If you do not recognize the names of either of these two games, you are probably a millennial. I told Duc2V4 that if he could find his own set of headers in this pile, he could have them for free. He blasted back "OK, they're all mine. Bazinga!" Yesterday the boxes and shipping materials arrived, so we are now prepared to strap, wrap, and slap shipping labels onto the suckers: -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Copy that, Voided. I’ll be home in 1/2 hour and PM you about schedule and a couple other items. Thanks -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Thanks Voided. The 8 gen header is in the works - coming up with a date to build and fit the prototype with Wade. Update on crush gaskets – over this past weekend, Delkevic sold all 50 of the 42 mm gaskets they had in stock. They will have more in 1 to 2 weeks, which may or may not line up with headers having been passivated. The math points to about half of those who have purchased headers having purchased crush gaskets. It will be simplest for the remaining people who want to purchase gaskets to contact Delkevic and place them on back order so they will have them on or about the date their headers arrive. -

VFR Alternatives / Where to from here?

sfdownhill replied to adamv's topic in OTHER Motorcycle Talk (non vfr)

The motorcycle in the link below is not brand spanking new, but with only 471 miles... Depends on whether your priority is purchasing a motorcycle that rides a lot like a VFR, or trying out a brand new zero miles non-VFR motorcycle that exhibits similar behavior. https://dallas.craigslist.org/ftw/mcy/6844800060.html -

VFR Alternatives / Where to from here?

sfdownhill replied to adamv's topic in OTHER Motorcycle Talk (non vfr)

What about a very low mileage 2014-2016 VFR in excellent condition? -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

So true. The irony in my case was that I had been working on a couple 6 gens and was prepared for and expecting the reverse threads. Then I went to take the center stand off of my 5 gen....I swear that bolt never even slowed down before it snapped off. I really like your idea for a clevis pin in place of the right side CS fixing bolt. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

With that many PMs, should we start calling you PMaster? Or maybe Message Man, and get you a set of leathers with a bold 'PM' logo? -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Hi Airisom - good question. We've run through the Delkevic gaskets we purchased, but it makes sense to order another slew of them so we can toss them [figuratively] into the boxes with headers. Delkevic charges $5 per gasket plus shipping. If we took on this additional task, individual purchasers wouldn't have to find and order gaskets, then pay Delkevic's flat rate shipping - the very small box of 16 gaskets weighed nearly nothing, and cost $11 to ship from Delkevic in Colorado to CA. The only downside here is that Duc2V4 has just finished doing an stellar job of putting together a master spreadsheet and individual invoices for each individual who has purchased headers. His thorough spreadsheets account for basic cost, shipping, insurance, passivation [if selected], extra bung [if selected], 5 gen or 6 gen configuration [5/8" difference in collector exit length], center stand stop [if selected], deposit placed, and sales tax where applicable. With headers set to be picked up next week, we can't introduce variables that could cause delays in gathering the funds we will need to pay Wade before receiving the headers. Does anyone have a suggestion for including gaskets and their cost without re-invoicing or slowing down the payment/picking up headers process? Half of the purchasers of headers have paid their final balances, and I'm sure the rest are about to. We'll have a week after picking up the headers during which most of them will be at the metal treatment company for passivation, so we can work out the gasket options then, before shipping. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Hi Scottie - we have two of this production run tagged for prototyping as 8 gen headers. We may not need both, so there may be a spare 5 gen header. That won’t be determined for two more weeks. When we suggested modular front primaries to Wade because they would allow simultaneous production of 5/6 and 8 gen headers, he stood firm - his process is to build one type of exhaust at a time, stem-to-stern. The mention of schedule brings up the cancellation of tomorrow’s 6 gen dyno day. Over the past 6 weeks or so (In our spare time!) we’ve been doing surgery and 3D R&D on Hammerdrill’s OEM 6 gen mufflers (I’ll try to start a new thread on this effort). Bottom line - we couldn’t get the mufflers done in time and decided to hold off on dyno tuning until we had the final configuration firing on all four cylinders - literally. The current reschedule of dyno time puts us on April 6 and April 9. Whichever bike is ready first - 6 gen or 8 gen - will go on April 6, and the other will be dyno’d April 9. Gotta git’er’done in time to head down to COTA. We are working hard to have both bikes ready well before April 6, so we can flip a coin instead of being rushed. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Having tried four different types of 42mm crush gaskets, we found the best option is 42mm copper crush gaskets from Delkevic (pictured in a couple places on this thread). The 42mm gaskets are not on Delk’s website and they do not sell them on ebay. I only learned of them because I was on the phone with Matt at Delk to order the 41mm gaskets they recommend for VFR800s (Hoping the 41mm gaskets would crush to a functional size) and Matt said they have and sell 42mm gaskets. The 42mm gaskets from Delk have a skinny, round cross section and crush to a perfect id that is larger than the VFR’s exhaust port. The Delk gaskets have a seam on one side - we put the seam side down, toward the head, to give the header’s collar a cleaner surface to press against. They create a good seal. All the other 42mm gaskets we tried were too big to fit into the head’s sleeve - where the headers seat - without grinding and/or cutting. I’m editing out reams of trial and error, grinding, cutting, splicing, and cursing data. Even the Delk washers are difficult to get started into the sleeve, but because they are so thin, they can be persuaded past the lip of the sleeve. After starting the gaskets in by hand, the headers do the rest of the job of escorting the gaskets into their final resting place, then crushing them. It’s a lovely kind of slow-paced violence. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

I sent a PM to BusyLittleShop asking about a quick release system for VFR center stands. Note - BLS has been logging pilot-in-command time in a P-51 Mustang lately, so he may be wonderfully preoccupied. Anything that can be turned up about this by searching this site and VFRW will be welcomed. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Here’s an important installation note about the new headers: using anti-seize on the head stud bolts (recommended) reduces friction enough that the 9 ft-lbs torque for the header nuts specified in the service manual has proven to be enough to bend even the thick, high grade stainless flanges Wade is using on our headers. We’re not sure if this happened because each of the two prototype headers has been installed and removed several times for fitment and dyno on both 5 gen and 6 gen motorcycles, or if 9 ft-lbs is just too much torque when using anti-seize. The flanges are still serviceable and nothing has broken, but bending where you don’t want it is always bad. As the flange bends toward the head, it likes to bend the head studs outward, which makes removal and future installations tricky. We’ll stay on top of this occurrence, try using less torque on future installations, and report back. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Hi MooseMoose - yes, the headers need to be removed in order to remove or install the center stand [CS]. It's the same with OEM headers. Being able to remove just one pipe on your Delkevic to remove or install the CS is a nice feature. Alas, it will not be so with the new headers. Another member was asking the same question you are - a lot of us like having the CS on for touring and off for sport or track riding. I mentioned to the guy asking the question that another member here - I'm pretty sure it was BusyLittleShop [One of our resident VFR gurus with an advanced degree in the RC45] had set his VFR up with a quick release system so that he could remove and replace the CS without removing the headers. It would be great if anyone has time to search out that thread and see what it says. Now that it's come up a few times, I'll PM BusyLittleShop and see if he can offer any insight. I had another thought on removability of CSs: since only the right side CS fixing bolt access is hindered by the headers, and the bolt hole for the right side fixing bolt goes all the way through the cush bracket, there might be a way to run a tap all the way through the bolt hole to clear the threads, then thread a bolt of precise length through from the center of the bike outward to a nut on the outside of the CS where the bolthead usually resides. This would allow removal of the bolt without removing the headers. NOTE - 6 GENS HAVE REVERSE [LEFT-HAND] THREADING ON THE RIGHT SIDE CS FIXING BOLT. 6 GEN LEFT SIDE CS FIXING BOLT HAS REGULAR [RIGHT-HAND] THREADING. ADDITIONAL NOTE - 5 GENS HAVE REGULAR [RIGHT-HAND] THREADING ON BOTH THE RIGHT AND LEFT SIDE CS FIXING BOLTS. [Please do not ask me why I'm so adamant about this or how I learned about the 5/6 gen CS bolt threading anomaly - it still stings a bit] -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

NO FRICKIN' WAY! When a project hits a couple of the 'just one more week' cycles, it raises one's eyebrow a bit. But here is physical molecular evidence of the cause of giant ____-eating grins on the faces of 22 VFR owners: Rows of cylinders 1-2 merges alongside rows of cylinders 3-4 merges: And here is a set of production headers just the way we like our women...almost fully dressed: -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Hi Weirdo - it's good to hear first hand that 5/8" probably won't matter on 5 gen. If the same holds true for prototype 1, we'll just have Wade slice 5/8" off each production run header's collector exit.