-

Posts

2,401 -

Joined

-

Last visited

-

Days Won

45

Content Type

Forums

Profiles

Gallery

Blogs

Downloads

Events

Posts posted by BusyLittleShop

-

-

Larry, if you ever find the right size belt - would the pulley weigh more than the sprocket?

Just curious, I know the belt obviously weighs less than the chain, still and in motion.

Here's how it all adds up... I'm most interested is reducing unsprung weight...

17T 525 stock RC45 sprocket 11 oz

40T 525 stock RC45 steel sprocket 1 lb 9 oz

43T 525 modified steel RC45 sprocket 1 lb 3 oz

43T 525 HRC RC45 aluminum sprocket 10 oz

110 links 525 DID VM chain 6 lb 10 oz

108 links 525 DID VM chain 6 lb 7 oz

Total stock 17/40 drive system 8 lb 12 oz

Total modified 17/43 drive system... 8 lb 11 oz

30T Buell steel sprocket 1 lb 14 oz

72T Buell aluminum sprocket 2 lb

155T Buell Gates 11mm Poly Chain 5 oz

Total Drive system 4 lb 3 oz

30T Buell steel sprocket 1 lb 14 oz

76T custom machined 7075 T6 Aluminum sprocket 1 lb 5 oz

172T BMW Conti Sport 11mm Poly Chain 8 oz

Total Drive System 3 lb 11 oz

-

That is... the COOLEST thing I have ever seen. Oh, to see Mr. RC45 slamming around a racetrack... preferably an FIM approved one, like Miller or Laguna. That would be a sight.

Lacy

Last time Mr.RC45 slammed Laguna with authority he was tagged with 103dba sound violation... that's 13dba

over the limit... the sound lady came out of booth just a shaking her finger at me like my mom... so I don't

think I'll go back for another scolding... and Sac to Miller to Sac is too great a trip...

-

How it all adds up:

Stock Honda 310mm stainless steel 3 lbs 4 oz

Ferodo 320mm Ductle Iron 2 lb 8 oz

Ceramic Matrix Composite 1 lb 7 oz

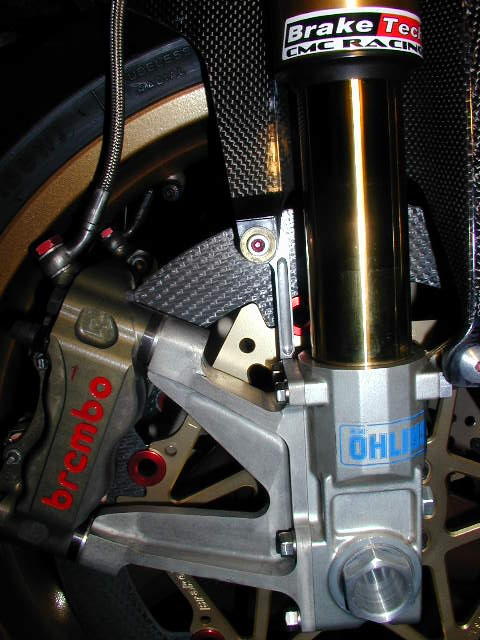

How much weight did you save with the Marchesini magnesium wheel, Brembo billet calipers, magnesium caliper hangers, 7075 T6 aluminum axle and QB carbon fender ?

Stock Honda 16 inch wheel 9lb 3oz

17 Marchesini 6lb 3oz

minus 3lb

Stock Honda steel axle and bolt 13oz

Aluminum axle 7oz

minus 6oz

Stock Honda calipers 2lb 6oz

Brembo billet calipers 2lb 1oz

minus 10oz

Stock Honda 310 stainless steel dics 3lb 7oz

Ferodo 320mm Ceramic Matrix Composite 1 lb 7 oz

minus 4lbs

Stock Honda 42mm Showa forks 8lb 8oz

Ohlins 43mm Superbike forks 7lb 13oz

minus 1lb 3oz

Stock Honda ABS fender 1lb

QB Carbon 6oz

minus 10z

Total front end weight lost since over stock is 9lb 13oz... and that's not counting all the titanium hardware...

-

The rear is stock stainless steel but I trimmed it and drilled it...

How about a magnesium brake caliper torque arm Larry? :biggrin:

Mercy... will our bikes ever be done???

-

So you are a bit ahead of motogp Larry? :unsure:

And besides the weight saving, they look good too :unsure: Do you also have a ceramic rear wheel rotor?

The rear is stock stainless steel but I trimmed it and drilled it...

-

Mmm... sexy...

How long do they last?

I believe they last as long as steel rotors...

-

Larry, you're one mad scientist!

That looks awesome!

So do they work OK when cold?

I've noticed no difference over the ductile iron rotors...

Performance features include:

-

Not thermally sensitive (will work great on the street)

-

Ultra broad torque curve across a very wide thermal range

-

Much longer lasting than Carbon / carbon

-

Much less expensive than Carbon / carbon

-

Great wet weather performance - unlike Carbon / carbon [not hygroscopic]

-

Terrific feel and feedback at the lever

-

Strong braking performance? We mean, Really strong: +.6 mu average friction with special Ferodo Racing brake pads

-

Not thermally sensitive (will work great on the street)

-

Since 98 I've been on personal quest to lower Mr.RC45's unsprung

weight to the lowest possible and now I'm happy to report success with

the addition of Ferodo's CMC rotors...

Sequence of events:

First came the 3.50 x 17 Marchesini magnesium wheel once owned by

Wayne Rainey...

Next came the Brembo billet calipers...

Then I machined my own magnesium caliper hangers...

I also machined my own axle out of 7075 T6 aluminum...

I added a QB carbon fender...

Finally the addition of Ferodo's Ceramic Matrix Composite rotors for a

3 lb drop in weight...

How it all adds up:

Stock Honda 310mm stainless steel 3 lbs 4 oz

Ferodo 320mm Ductle Iron 2 lb 8 oz

Ceramic Matrix Composite 1 lb 7 oz

Quote my good friend Jeff Gehrs of Brake Tech USA

"Brake Tech USA is very pleased to announce the release of the long

awaited, ultra-advanced technology Ceramic Matrix Composite brake

rotors for the Motorcycle Industry. The AXIS/StarBlade™ is the new and

updated MKII version incorporating now de-classified Stealth Bomber

Aircraft technology manufactured by Starfire Systems, this

revolutionary material will change the way both top-level race teams

and enthusiasts alike view their braking systems. The performance

parameters in-total make all previous materials and systems dated by

comparison, including the vaunted Carbon/carbon brakes. Designed to

perform brilliantly with OEM calipers as well as the Billet GP

race-spec versions. This all-new composite material offers the best

features of premium iron rotors with the incredible lightweight of

carbon, and none of the Carbon/carbon foibles!"

-

Could you take some pics of how much fling off there is after using it? I'm rather intrigued by this pro oiler idea, but am not sure about the fling off.

You can always find your back home by following the oil spots...

-

The difference being that you now have to keep an extra close eye on your oil level. Low oil in the resevoir of the pro-oiler means you have a dry chain. Low oil with your method means you're about to have issues...

It is written in your owners manual... check oil level on the pre ride inspection or risk being arrested for bike abuse...

-

Eastest way to have a pre oiler is to nick the seal behind your countershaft sprocket... you get a running oil

leak that is not only hot but unlimted as well... Honda's old 305s use to sport s screw at the end of the

countershaft that was designed to meter hot oil on the the chain... with the advent of the O ring chain this

was no longer cost effective so Honda dropped the feature...

-

Maybe I'm just missing something here (distinct possiblity), but what about a tensioner on the bottom side of the swingarm inside of the belt. I couldn't really find a close up of a rc45 swingarm, but from what i could see the exhaust gets real close to the bottom side ( granted that was on a standard rc45, and from what I understand, your's is rather extensively modified so it could well be different ). Go with the mount of the tensioner closer to the pivot point of the swingarm, and the tensioner pulley closer to the rear pulley. Granted I have no answers for how to mount the tensioner. Not sure how keen I would be on drilling mount holes through the swingarm (especially on a rc45...imagine those aren't cheap...) or doing any other type of permanant mounting solution. *shrugs* Just a thought.

Oh yeah, fantastic work on the rear pulley. God that's beautiful. Made me drool.

Thanks but you did miss the part about rollers...

I already thought about rollers... but the BMW belt is

kind of rubbery whereas the Buell belt is more plastic... the

different being you can run a roller against Buell belt but not

against the BMW belt without taking the life out of it... besides I

don't have the room on Mr.RC45 dense packaging...

-

Sorry you are having such a difficult time making this conversion. Closest you can get to 628mm center distance is by using your 30 tooth Driver sprocket and an 85 tooth rear wheel sprocket with the 173 tooth belt. This will give you a center distance of 627.85mm. Just make sure that you are working with the correct center distance to begin with! It would be best if you could provide a center distance range (Min to Max) to make sure the belt will install properly and still be tensioned. If you need additional calculations please contact me. Bruce - gto_65@hotmail.

P.S. I'm a Gates Engineer :cool:

No problem Bruce... Honda thinks it's impossible to belt drive their bikes but I'll show them... I apprericate

your suggestion but I don't have the clearance to run an 85T rear sprocket so I'm screwed... but you can

help... there's a little known 11 pitch belt manufacture in Gates Japan rumored to be 160T... that might

work if I drop to 29/68 sprockets for a 2.35 ratio... you see stock RC45 final drive is 17/40 = 2.35 ratio...

-

Thanks Keith... I won't be able to make it up... but I'll be thinking of my RC brother Rich none the less...

-

So is this your work then, Larry?

This Tim's work with the help of a local CNC shop...

-

No longer made out of "Unobtanium".

The real deal just back from the CNC machinist. I popped the stem in moments ago using the old oven/freezer trick

(mucho thanks to Busy Little Shop :biggrin: )

Thoughts?

You're welcome Tim... the clamps look the biz... 40mm offset is very important because it preserves the VFR

quick handling rate whereas the stock RC51 offset doesn't... the only the thought that comes to mind is to

gull the top clamp like the bottom in order preserver the VFR's front end height and in addition there might

be enough room to hang a clip on...

If you weight them post the number so I may advise prospective customers...

-

prototype_pics.jpg

Looking at your turbo bracket I'd subtract the triangle cut out for lightnest and add the metal back for

strength... this beautiful machined aluminum piece looks crank prone to me in that junction...

-

I like my widdo bang :biggrin:

good read about the development. the whole theory about allowing the back tire time to rest and "plant" itself before being hit by power is interesting.

It's interesting to note the difference on an unspecting rider's seat of the pants... like my

friend Andrew who normally rides an S3Triumph Triple...

"It was time to trade bikes! I took off on the Mr.RC45. OMG. The RC45

is amazing. It feels nothing like a VFR motor (Which I don't think is

anything special, anyhow.) The RC45 motor is amazing, smooth, torquey,

not at all lumpy like I think of the VFR. Larry may have converted me to

a V4 aficionado."

-

Mick Doohan and the Big Bang connection from the pages of MCI

magazine:

Developments of the 91 NSR 500 focused around Doohan testing a number

of designs as HRC shifted their main push behind the new up and

comer... For some while Doohan had been asking engineers to replicate

the wide power band characteristic of the RVF750 4 stroke endurance

bike, which he and Gardner had used to lead the previous summer's

Suzuka 8 Hours... HRC answer was the 2 stroke equivalent of the the 4

stroke Big Bang... technically speaking all four cylinders fried

within 70 degrees to afford the tire more time to hook up...

Consider and instant success by Gardner "Jesus, this is amazing" but

Doohan was a doubter... the 92 NSR droning big bang had a very flat

exhaust note which made it sound slow to riders... It was only during

HRC's final preseason phase that Doohan began to believe in the Big

Bang... He found little difference in lap times but the close firing

order was easier on tires and set up...

Rainey and company were in for the shock as the season kicked off...

Utilizing the Big Bangs ability to find traction where others could

not... Doohan ran away with the first four races... winning by

anything up to 28 seconds wet or dry... The Big Bang proved such a

giant leap forward that rival factories Cagiva, Suzuki, Yamaha rushed

to build copies... having learned the NRS's secret by playing track

side audio recording against an oscilloscope...

There could be no doubt now... Honda now had the best 500 on the grid

by quite some margin... the big bang NRS proved to be a winner in a

variety of hands... Since the 80 when engine HP dramatically

outstripped tire and chassis performance... GP teams had been hiring

tail sliding dirt trackers form America and Australia because no one

else could wrestle these monsters into submission...

Honda only raced the big bang 360º crank... and every V4 they produced

was big bang... but that all changed in 86 with the 180º V4 crank...

Honda was loosing marketing shares to the inline and they split the

crank throws 180 apart to change the pitch from a drone to a scream...

this move sold more V4s but it also muted the drive out of the

corners... you'd have to compare a your 180 5th Gen VFR with an 360

RC45 to get my point... they are basically the same engine except with

regard to crank throws...

Technically speaking 360 means all 4 crank throws rotate together in

one 360º circle whereas the 180 means the 4 crank throws are split

180º apart... it's independent with regard to the 90º cylinder

angle...

I think Honda should design the next Gen VFR without the silly Vtec

and adopt the visceral 360º big bang crank of their race bred V4s...

RC45 360º big bang crank...

VFR 180º little bang crank...

-

Admittedly in my engineering travels I have not had the opportunity to play with magnesium. But doesnt that material degrade over time? (years) Kinda why the major mfrs avoid it for structual parts?

I'm thinking 2024 is a strong candidate.....

MD

Magnesium resistance to weather exposure is good in rural or inland atmospheres... color will

change to dark gray if unprotected... parts may be treated in Dow 7 giving magnesium the

characteristic chocolate brown color so many motorcycle parts are painted to resemble... Dow

#7 is dichromate treatment...

My triple clamps were treated to MIL process which is a chrome pickle treatment for magnesium.

Color may vary from matte gray to yellow-red...

-

BLS, those triples are things of beauty & grace. Did you make those on a conventional Bridgeport type mill?

Thanks... like everything I machine at the Busy Little Shop they were

done by hand eye coordination on a Taiwan copy of a conventional

Bridgeport mill...

-

Can't wait to see it all in 7075-T6. Now hurry up so I can finish assembly :blink:

Just for fun - ok I'm a sick bastard.....

For the sake of engineering argument on materials, what about a 5000 or 2000 series aluminum such as 2024-T3? The 7075-T6 is strong as hell, but not so great in the fatique end of the stick. -It still maybe the best, just want to here other opinions.

MD

How about Magnesium??? I machined Mr.RC45's triple clamps out of this least understood

metal of motion... I think it's by far the best and lightest material...

7075 T6 is one of the highest strength aluminum alloys available. Its strength-to weight ratio

is excellent and it is ideally used for highly stressed parts... consequently you may design the

triple clamps with a thinner wall thickness and still achieve the desired strength...

2024 is one of the best known of the high strength aluminum alloys. With its high strength

and excellent fatigue resistance, it is used to advantage on structures and parts where good

strength-to-weight ratio is desired.

-

Tim... I'd design a little more metal in the area of the pinch bolt threads... you can use the

amount of thread engaugement that's in the stock Honda tree as a guide...

-

Would it not be possible to shrink your pullies to lengthen the shorter buell belt?

Costs are going back up, but if it lets you achieve your goals then why not? This would also allow you to run the Buell style tentioner, would it not?

If I shrink my pullies to the absolute minimum the buell belt is still too short...

There's no room to run a Buell style tentioner...

Success... Ferodo Cmc Disc Completes Front Ungrade...

in Modifications

Posted

As you know Rob thats easy for me to fab but any extra weight on my $2,800 hand made custom titanium

pipes is too risky at race pace... some of you electrical genious out there needs to invent an anti sound

system that cancells dba like the Bose system does...