-

Posts

2,400 -

Joined

-

Last visited

-

Days Won

45

Content Type

Forums

Profiles

Gallery

Blogs

Downloads

Events

Posts posted by BusyLittleShop

-

-

Hmm, Goodyear seems to say otherwise:

True but Eagle NRG’s patented Helical Offset Tooth only comes in 8mm which not enough tooth grip and

14mm which has tooth grip but the primary sprocket is too large to fit in the parameters... the only

answer is the 11mm pitch belt which has tooth grip and small enough sprockets to fit... keep in mind

that each belt require certain radius to live... you can not bend a 14mm pitch belt around the tight

circumference of a 11mm sprocket...

-

Did I ask this before Larry? What about a herringbone pattern belt like the GoodYear NRG belt?

I think it came up before Rob... there's just not enough tooth grip...

-

Hi Larry,

Sorry to resurrect a sore subject but Gates manufactures an insane number of different belts. Have you contacted their engineering department to see if they have what you need or are you just checking publications regarding motorcycles? Maybe they manufacture the belt but its for a car, industrial equipment, etc?

PM sent to bring Larry`s attention back to this subject and providing a little bit more information.

No problem... yes I have contacted Gates engineering and the 11mm pitch belt are

only custom made upon demand for Eric Buell and BMW... the 155T Buell is too

short and the 172T BMW is too long... what we need is a 166T to have any chance

at a RC45 / VFR800 11mm belt drive conversion...

-

Here a German guy selling belt conversion kits. But no Honda's in his range....

Good find but I can't find any belt pitch numbers... the photo shows a belt with small teeth which

makes me believe its the light duty 8mm pitch belt... what we need to crack the RC45/ VFR belt code is

a robust 11mm pitch belt because the Harley 14mm pitch belt will not bend around a sharp enough radius

to fit in the space of the counter shaft sprocket...

-

1

1

-

-

I am wondering what the better solution would be:

1. use a spacer between my Gen 6 rear wheel and my Gen 3 SSA hub interface

2. Dremel the Gen 6 rear wheel mating surface to clear the exposed bolts coming out of the gen 3 hub

The short of it is that I want to swap rear wheels between my Gen 3 and Gen 6. The 8-spoker '93 wheel works great on the 2004. but, the reverse is not true. I would rather not hack up the 5-spoker rear wheel, however.

Suggestions?

I'd counter sink the hub and run the bolts on the other side...

-

Wow, has it been 6 years???

I haven't taken the BLS blocks off, Still running them, still working great.

Pay careful attention to the footpeg feeler mod I did, it's perfect. I would recommend the same.

Its hard to believe but Peg Blocks, an exclusive VFRD product; is

entering its 6 year of keeping those knees in the breeze... I want to

thank Rob for his ingenuity and support that he tirelessly gives to

the membership and there's a table at Bubba Gumps reserved in your

name Rob anytime you return to Laguna Seca...

-

Why not go with what the manufacturer calls for?

You'll find owners who change your oil at 2K all the way to 8K manufactures recommendation but whats constant is the fact not one of them complains about wearing out their engine before its time... 8K interval is the safe limit of how long the additive package last according to the test by the Honda engineers... if an owner is in doubt then I suggest sending a sample to Blackstone labs to know for sure if their additive package is still robust enough for use or not... the only thing I hate is not knowing something...

-

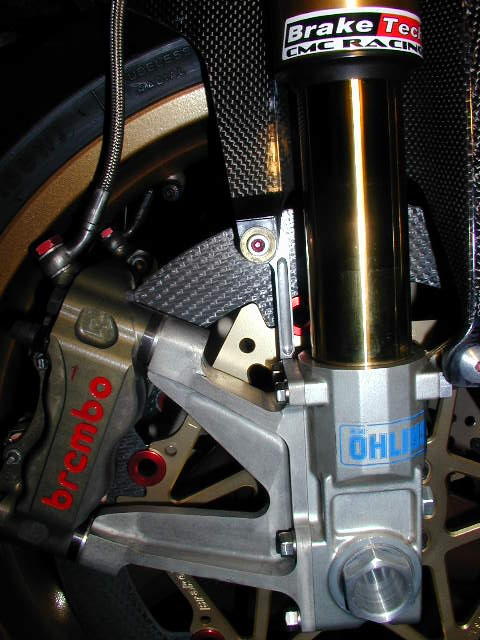

Hey Larry, as always excellent work. Love it. I didn't see your CMC front upgrade before, is there a thread for it ?

How long did the mods to the disc take you ? That is some serious machining. I've never seen the CMC material in the flesh, is it more like a metal or a ceramic ?

Keep up the good work.

Thank you... My CMC upgrade was in 2007 and its no longer on the site... I've been

working on the CMC rear mod for 2 weeks... CMC is more like ceramic

than metal... and I might add very dusty...

Nice is it a smooth brake feel or is it grabby?

I haven't tested hopped the new rear CMC but I've been using Brake

Tech's CMC disc on the front since 2007... This all new composite

material offers the best features of premium iron rotors with the

incredible lightweight of carbon and none of the Carbon/carbon

problems of thermally sensitive... unlike Carbon carbon they are not

hygroscopic so they perform the same as cast iron in the wet no more

or no less... my experience is all positive with terrific feel and

feedback at the lever regardless of out side air temp... the only

caution is to make sure your brake fluid is fresh (no brown

discoloration) because they will heat up the pads... I boiled my Motul

Dot 4 during numerous 140 to 0 stops to bed in the pads as advised by

the break in flyer...

-

That is really neat stuff! How much does Mr. RC45 weigh now? And what were they stock?

Thanks... 404lbs tank empty and 431 tank full... I've taken 30 pounds off

Mr.RC45 since 98...

-

MotoGp technology for the street... Sicom's Ceramic Matrix Composite

(CMC) rear disc is light as carbon but sports an everyday workable

alternative to the heavier steel disc... the CMC disc stops from the

get go no matter wet or dry... someday I hope this technology may

become to norm for top shelf bikes...

Check out Sicom's other line of CMC disc for motorcycles

http://www.sicom-brakes.com/html/motorcycles.html

Sicom's (12oz / 340gm) CMC disc was for a Ducati 1199 Panigale

but this is how I modified it to fit Mr.RC45 employing my Mill and

Rotary Table...

I wanted dead nuts accuracy so I located the center of the Ducati's

110mm bolt circle with a wiggler and then wiggled the Honda's 120mm

bolt circle...

The bolt hole was cut with a .312 Carbide Ball End which comes out the

other side without chipping...

To size the bolt hole to fit perfect with the Titanium fastener I used

a stone hone...

A .500 Carbide Rodman bit was employed for the other holes to lighten

the disc and give it the shape I wanted...

I used a Ceramic cutter to trim off the excess diameter surgically...

I angled the Mill head 45º to give the edge a crisp 45º cut...

Finish weight was 7oz (198gm) thats a 1 lb 14oz (849gm) savings over

the stock Honda steel...

The sinter pads that came with the CMC disc are milled down to fit my

4 pot Gp Brembo...

You have to feel it to believe it but my finished Ceramic Matrix Composite disc only weights 7oz...

Now my rear disc is CMC like my front disc...

-

1

1

-

-

-

I realize that this thread is quite old, but I'd like to chime in with hopes of educating anyone new that may see this forum. I'll just go with Keith Code's words of wisdom in saying that there is never really a time where engine braking is necessary. As he says, brake pads are cheap to replace, both in time and money. Engines are not. Use your brakes. Check out 'Twist Of The Wrist', very informative and a must-have for every rider.

What my friend Kieth Code will clarify is first you have to learn brake less cornering before you can get up

to speed enough to use your brakes on the track...

-

I use T-6 in my 5th and 6th gens and they both shift like butter . . .

When my customers complain about shifting my experience it

can be traced to clutch drag and not the oil... I doubt a

rider can tell the difference in a BLIND shift test...

usually a rider develops a feeling about an oil based on how

enjoyable they are traveling down the perverted highway...

like toilet paper you can roll freely or wipe sh*t off

someone's A hole...

So here's my method to check your clutch for drag... your

gears can't shift smoothly if your clutch is part way engaged...

1 Place your bike on the center stand...

2 Start engine and establish a steady idle...

3 Squeeze in the clutch and hold... shift into first gear...

4 Now look at the rear wheel... if it's spinning step on the rear brake...

does this action drag down the engine rpms???

If you bike is equipped with an cable then adjust the clutch lever

knob clock wise (out) 1/4 turn and check again check for clutch

drag... if you bike is equipped with hydraulics bleed system and check

for bubbles...

Ultimately you want the rear wheel to stop when the engine is idling

and first gear selected with the clutch lever is squeezed in...

In conclusion

After 25 years dealing with customers I think its not a question of

oil so much as a question of technique and clutch...

My RC30 and RC45 customers will ask for the same slick shifting oil that

made their friend's RC30 and RC45 shift so smoothly after it left the

Busy Little Shop... I hate to break it to them but it wasn't the oil

that made the difference it was rider technique and the elimination of

clutch drag... so before I will dump one slick shifting oil for the

next slick shifting oil I work with them on their technique and their

clutch... then and only then will they understand that they were

fooled into thinking it was the oil when in fact it was technique and

clutch...

I think we are after the same thing... smooth shift without upsetting

the suspension... the secret is moving the foot quicker than clutch or

throttle... go easy with the clutch and throttle but move your foot

quicker... but worry there is no such thing as too quick... its early

form of seem-less shifting...

-

Mercy... what in hell is an over weight car wheel doing on a VFR??? I'm going to have to report you to Honda for adding what amounts to a brick to their bike...

-

Well, I put Larry's 0W30 M1 in my '97 last night and rode to work today. Air temp on way to work 25F, on way home 37F. I had M1 10W40 motorcycle oil in it. Starter had and easier time spinning it to start and cold idle was higher. Less internal engine noise until it warmed up, then the same as normal. Shifting seems a bit notchier than with the 10W40. It seems overall to like the 0w30 in these colder temps, may work out great as a winter commuting oil. Because of our temp extremes here in New Mexico I feel I have to change twice a year 'cause I ride year round. This stuff and the M1 10w40 bike oil may be my 4th gen's diet for the future.

Thanks for the report... may I quote you in an another forum where they believe 0W30 is "horrible" for our engines???

-

I dont presently have a camara or camera phone , and I thought I might have one stashed on photbucket, but no dice.

so here's the numbers from Blackstone

Your motor is showing High Lead in the oil, probably , which may be due to Racing.

(next round, I told the its from leaded race fuel, they were relieved LOL!)

amsoil 15w40 1900 mile on oil Rotella 5w40 1100 miles on oil

alumi 8 alum 6

iron 9 iron 7

copper 1 copper 1

tin 1 tin 1

moly 3 moly 6

boron 1 boron 0

silicon 3 silcon 4

sodium 4 sodium 6

cacium 3170 calcium 2670

magneisum 8 mag 7

phos 1065 phos 1003

zinc 1289 zinc 1150

flash 370 flash 360

sus vis 62.9

insolubals .1

thats all i have its 5 years ago when I did this, miles on bike on both oils under 8,000 miles

Thanks... sus 62.9 is equal to the viscosity of 11.1 cSt

-

Through oil analysis

Good... what lab did the analysis??? and post them up for all to see...

-

On a side note My vfr 5w40 Rotella loses a full Grade by 1100 miles,

How did you determine your oil lost a full grade in 1100 miles???

-

I said MB rated oil like your ow30 mobil1 doesnt meet the MA clutch friction gate,

An oil that meets JASO-MA is considered appropriate for wet clutch operations. Oils marketed as

motorcycle-specific will carry the JASO-MA label. A properly specified motorcycle oil will still allow for

the appropriate lubrication and cooling of a motorcycle clutch, whilst maintaining 100% of the drive

to be transmitted by the clutch, even under arduous operating conditions... Mr.RC45's tall first gear

good for 90mph operates under arduous conditions on the street and track... and I'm here to report

that Mobli 1 10W30 or 0W30 has maintained 100% of the drive of 116RWHP... so for all practical

purporses I've meet and passed the MA clutch friction gate test... so do you still think 0W30 won't

pass mustard with your VFR's clutch???

but Low weight energy efficient oils are going to be full of Polymers strands.

Techincally speaking straight dino oil employs heavy polymers but synthetics employ either light

weight polymers or no polymers at all...

Quote Oil Bible

Unfortunately, because petroleum basestocks (dino oil ) are so prone to viscosity

loss at high temperatures, high molecular weight polymers must be

used. Since these polymers are more prone to shearing than lower

molecular weight polymers, petroleum oils tend to shear back very

quickly. In other words, they lose their ability to maintain their

viscosity at high temperatures.

Synthetic basestocks, on the other hand, are much less prone to

viscosity loss at high temperatures. Therefore, lower molecular weight

polymers may be used as VI improvers. These polymers are less prone to

shearing, so they are effective for a much longer period of time than

the VI improvers used in (dino) petroleum oils. In other words, synthetic

oils do not quickly lose their ability to maintain viscosity at high

temperatures as petroleum oils do.

In fact, some synthetic basestocks are so stable at high temperatures

they need NO VI improvers at all. Obviously, these basestocks will

maintain their high temperature viscosities for a very long time since

there are no VI improvers to break down.

Ive ran real synthetic , not the group 3 mobile one stuff, in 5 w40 weight Group 4 PAO oil and obvious cam lobe wear within 30,000 miles

What year VFR was this and how did you note the obvious wear??? Did you Mic the cam to follow up your assumptions???

-

-

Interesting read BLS, how would trying this fare against a southern AZ summer? Many times last summer it was 105-117 outside during my commutes and long weekend rides. What would you suggest in that case?

My choice would be either a 0 30 or 0 40 depending on coolant temps... never 15 50...

Since 98 Mr.RC45 and Mobil 1 10W30 has gone through the summer months here in Ca with

outside temps over 100ºF... this summer I shall run Mobil 1 0 30... my coolant temps stabilize

between 212ºF and 230ºF... only at stand still do I see 230ºF but as soon as I drop the clutch the

temps fall... I have over 55K miles on the clock and Larry Calamari is not known to ride in moderation...

One rating to know is a Oils HTHS rating taken at 302ºF / 150ºC...

HTHS stands for High Temperature High Shear and what it means is that

if you somehow allow your engine reach 150c or 302F the 0 30 oil will

flow at a viscosity of 3.06... but In order to run 302F our

coolant systems would have to fail or we would be racing wide

fooking open on a track...

The thickness of moving oil is measured in centiStokes or cS. The

motorcycle engineers design the pump and blow off so the ideal oil

viscosity is around 10 cS at normal operating temp of 100c or 212F...

The really thick multigrade oils such as 50Wt have a viscosity of 20

cS at operating temperature. Contrary what some people believe 50 is

not twice as thick as 30, it is only 10 cS thicker... or 10 cS free

flowing...

As we increase the heat from 212 F to 302 F my recommended 30 wt oil

thins from 10 cS to 3 cS... a 50w oil drops from 20 cS to 4 cS. Note

that in a very hot engine the difference between the two oils is now

only 1 - 2 cS. In other words they have about the same thickness.

There is little advantage to a thicker based oil as a 15W-50 at very

high temperatures... its a fact that the 4 cS oil is not twice as

thick as the 2 or 3 cS oil. This difference is measurable but no

cause for alarm...

There is a huge advantage of using the free flowing 0W-30 at startup

where 90 percent of the engine wear occurs. At 75 F the free flowing

0W 30 has a viscosity of 56 cS while the less flowing 0W 40 oil has a

viscosity of 80 cS. The less flowing stuff is 24 cS slower. This is a

much bigger difference than the .44 cS at HTHS...

-

So, Mr. BLS, what IS the moly content of M1 0W30? It's been very cold here (single digits to low teens in the morning) and I'm thinking of trying this.

I don't know the moly content of M1 0 30... but I've sent for a Blackstone test bottle to find out...

Additives fall into several basic categories but Moly is the most

often used friction modifier because it has such a high melting

temperature (4730¯ F versus 2795¯ F for iron), it works great as a

high-temperature, high-pressure antiwear agent. Some claim that

because moly is so slick, it can cause clutch slippage... but note

that 6 of the 19 motorcycle oils Sport Rider tested used moly

including the HP4 market by Honda for any of their motorcycles...

-

1

1

-

-

Im sure the MB1 will accelerate failure long before a Good clutch oil.

Negative... synthetic oil does not accelerate failure... syn oil cools and prolongs our clutches... if you wish to note accelerated failure take it to the drag strip or race track...

-

10w30 will actually be thicker than straight 30 weight at full temperature, There's no polymers in straight 30 weight to Hold the viscosity, straight 30 weight, the hotter it gets the thinner it gets, damn near water, on a hot drain. Ive never seen a 10w30 with Polymers thin that much, Polymers is what maintains the visosity in mutigrades, as it heats, and multigrade group 2 and 3 oils have alot polymers, Now they say Polymers by themselves arent very good at lubricatiing. so is a thicker 10w30 at full temp with polymers, more protective than a thinner straight 30 weight with no polymers? Idont now but I can tell you stright 30 weight scared the Livin chit out of me, it was so thin, it drained in 30 seconds and not a drip afterwards PURE WATER!!!!!

True a straight weight 30 wether dino or synthetic does not use polymers

to stay in grade but also true that synthetics multi grades use little

or no polymers to stay in grade... the same can not be said about dino

multi grades... their base stocks are usually a 10wt oil and employ

polymers to flow like a 30 weight when hot... I confirmed with a Mobil

1 Technician that their 100% synthetic oils in grades 0 30 / 5 30 /

10W 30 are all essentially a 30 weight oil and can not be thinned by

the action of shearing... this is good news for us with engines that

share oil with the gear box...

Water is a molecule... the size of the molecule does not change but

the ability of water to flow does with temperature... H20 molecules

can be hard as ice... flow free as water or seen invisible as vapor...

but the size of the molecule does not altered its size... a 30 weight

oil molecule is the same size cold or hot but its ability to flow is

altered... cold it flows like molasses and hot it will flow like

water... we can't lubricate our engines with oil that flows like

molasses whereas we can lubricate our engines with oil the flows like

water... we should take it as a good sign that our engines are

protected by the hot flow of oil that reminds us of water...

The Official Oil Thread

in Maintenance Questions

Posted

Allowing the oil to reach operating temp is a good advice... but all you need to do to lower your summer

operating temps and enjoy about 5HP more is to choose the recommended 30 weight...