-

Posts

111 -

Joined

-

Last visited

Content Type

Forums

Profiles

Gallery

Blogs

Downloads

Events

Everything posted by cassandtim

-

40mm from center of steering stem to center of fork tubes. Stock VFR offset = 40mm RC51 (SP1) = 30mm This offset difference was one of the deciding factors in having this clamp set made because the overall effect on trail in doing the conversion.

-

Nope, not Mechanical Desktop. I work in the civil engineering trades and own a licensed copy of Civil3D/Land Development Desktop from Autodesk. It just so happens that it runs on the plain-jane AutoCAD engine and you have the option to open it up as regular ol' AutoCAD 2009. BTW, I knew nothing about 3D modelling in AutoCAD prior to modelling the mirror mounts for Darth Bling and then this project. Cool stuff though. It's nice to know that you can make all those parts you really want that nobody else (parts manufacturers) is bothering to offer.

-

I used the stock RC51 (SP1) steering stem. I do intend on modelling the stem as I would like to have one machined that uses the internal thread style top bolt similar to the Aprillia and Ducati stems. Because the stem and lower clamp use a force fit (0.002") I put the clamp in the oven at 300º for 35 mins and the stem in the freezer overnight. I put a little marvels mystery oil on the stem as well per Larry's advice and they went together with a tap from a dead-blow hammer and hardwood dowel. Because I'm going the "Superbike Bar" style setup there's no need for clip-ons. I did do the measurements on fork length differences and it came out (measured from center of axle to top of fork): Stock = 772mm RC51 (SP1) = 759mm Stock fork is supposed to be set 41mm from top of top clamp to top of fork (per Honda service manual) So I should have 28mm of fork tube above the top clamp when done. I have pondered modelling a set of gullwings in case somebody would rather go with clip-ons. It's all about finding the time. I will weigh these after I get them back from the anodizer but I suspect that with the bar clamps and associated hardware they will weigh a little more than the stock RC51 triples. I am hoping that I might be able to offer up the .DXF files after I verify that everything works well on my bike so that others can do this same conversion. I have discovered through this whole process that "where there's a will, there's a way" and it's not as tough as initially thought.

-

That's a great idea that I never thought of. This kind of gave me the excuse to buy the titanium hardware. I had said to Magellan and Darth Bling earlier in this project that I would buy the exotic stuff if I didn't have to pay more than $100 for it so the necessity/opportunity more-or-less pushed me over the edge. I am, however, concerned about potential galling between the 7075 and the titanium. I have some Vibratite thread patching compound that clearly states that it minimizes galling/stripping. I hope that I don't have too much to worry about. I believe that these would work on 5th Gens. That is, if it works on my 6th Gen after bolt up.

-

Dude, you're killin' me! "No beer for you!" I forgot to mention that the machinist made one small mistake when tapping the holes in the top clamp for the bar clamp mounts. He tapped the hole with an M10x1.25 instead of the standard M10x1.5. I panicked when I couldn't find any stainless socket head capped bolts in that thread at Mcmaster-Carr. When I googled the thread size the first place that came up was Yoyodyne and their vast supply of titanium bolts. Ugghh. I then had the dilema of purchasing the two bolts that I depserately needed for the bar mounts and use stainless for the rest or go "whole hog". Well, $220 bucks later I'm in it for the win! I sure hope to hell this whole thing turns out ok.

-

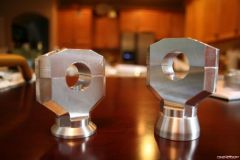

No longer made out of "Unobtanium". The real deal just back from the CNC machinist. I popped the stem in moments ago using the old oven/freezer trick (mucho thanks to Busy Little Shop :blink: ) Thoughts? Triple Clamp Assy 072108.jpg Here's a view of the two different size risers I had made (7mm & 17mm): Risers 072108.jpg The view of the bottom of the bottom clamp (massive): Bottom Triple 072108.jpg And finally, a view of the bottom of the top clamp: Top Triple 072108.jpg They're off to the anodizer tomorrow. With any luck I'll have the bike back together for the Kootenay Hootenanny PNWVFRD Meet '08 in August. Woot!!!

-

From the album: VFR-RC51 Triple Clamps

© ©vfdiscussion.com

-

From the album: VFR-RC51 Triple Clamps

© ©vfdiscussion.com

-

From the album: VFR-RC51 Triple Clamps

© ©vfdiscussion.com

-

From the album: VFR-RC51 Triple Clamps

© ©vfdiscussion.com

-

Oh, and BTW, my 7075 material is in and my machinist says we're cued up to begin this weekend. If all goes well I will post up photos of the finished product early next week! Woot!

-

Spiegler USA offers the LSL superbike kit for VFR's with stock front ends. http://www.spieglerusa.com/cfm/sbk.cfm

-

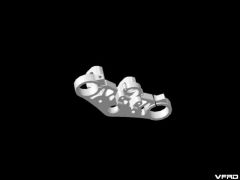

Ok, so I've got the lowers modelled (see below) and I'll meet with my CNC Machinist tonight or tomorrow to discuss the particulars. I'll probably redesign the steering stops and make them a bit more angular (easier to cut?). They still need to beefed up towards the bottom as the stock lower triple is flat and this one is gull-wing in shape based on the stock RC51 lower. I'll post up when I get estimate on material cost, machine time, and machining costs later this week. Lower Triple: VFR Lower Triple Iso 4.jpeg VFR Lower Triple Iso 3.jpeg VFR Lower Triple Iso 2.jpeg VFR Lower Triple Iso 1.jpeg Final Assembly: VFR Triple Assembly 1.jpeg

-

From the album: VFR-RC51 Triple Clamps

-

From the album: VFR-RC51 Triple Clamps

-

From the album: VFR-RC51 Triple Clamps

-

From the album: VFR-RC51 Triple Clamps

-

From the album: VFR-RC51 Triple Clamps

-

Wonder no longer for I am here temporarily to explain all. Well almost all :biggrin: Please keep in mind that I work in the engineering (Civil) trades and suffer from a severe case of OCD. I realize that most of what led me to this is complete overkill for the average person that wants to do the conversion. I had a visit last Thanksgiving at BLS's place and we had some fairly in-depth discussions concerning the fork offset of the VFR (40mm) vs the RC51 (30mm) and the effect the conversions have on the stock VFR geometry. I went home and began to do some research and analysis, mostly analyzing the geometry in AutoCAD and looking at the changes that occur when the offset difference is applied to the VFR. At that point I had no intention of attempting to manufacture a set of triples as I felt that I could live with the geometry changes. I actually had a couple of RC51 triples (stock & Vortex brand) and my original intention was to use one of them with a set of MX bar clamps. I even looked at the LSL riser bar option for the RC51. A fews things soon became apparent; the first being that the ignition switch will not bolt directly up to the stock RC51 triple top triple without modification (cutting or grinding). The second is that I run a RAM ball mount on the two bolts that mount the front of the fuel tank; with the RC51 LSL kit I would have to remove that as there would be interference there. Third, I wanted to use a set of preload adjuster knobs on the forks (yes, for the bling factor) and there was no way that they'd fit under the bars with the 30mm offset. I came to the conclusion that, for me, it would be easier to try my hand at modelling what I want and having them CNC'd than to deal with modifying parts to fit my needs. After working with Darth Bling on the GSXR mirror mount models I knew that it couldn't be that tough to complete these and it's kind of fun too (in a sick OCD sorta way). I'm trying to find a balance between form and function even though I might be leaning towards form a little more. Like I stated before: for most it will seem like a ridiculous exercise but, as most of my riding buddies here in the PNW can attest to, I'm a perfection freak . I should be wrapping up the lowers today and will meet with the machinist on Monday. If anyone has any questions (besides "why?" as I've tried to explain that here) feel free to post up or send me a pm. Cheers, Tim

-

After all of the bonehead questions you've answered for me Rob, I'll customize it anyway you want :biggrin:. Cheers, Tim

-

Yeah, it looks kinda slim in there but I used the Vortex RC51 top triple to get a lot of the measurements from. There's actually about 15mm of bite on the short side there, which is 5mm more than the Vortex. I'll email you some close-ups when I get time this week. I'm almost done with the lower triple, then it's off to meet with my CNC guy on Tuesday. I gotta get this thing done as it's totally holding everything else up. Should be kind of neat when I'm done. The thing that I think is coolest is the abilitiy to adjust the bar height by changing the size of spacer under the lower bar clamp block. Talk with you soon Larry. Cheers, -T

-

Well the story starts out with my motorcycle accident last August during Sportbike Northwest. I made the decision to rebuild the bike but wanted to upgrade the suspension by doing the RC51 fork conversion. After seeing how many issues that I was going to have to deal with (geometry issues, wanting superbike bars, etc.) I just decided to go ahead and design my own triples for the conversion. Below are some pictures of what I have modelled so far. Any inputs are welcome. I'm off to design the lowers now. Cheers, Tim VFR Top Triple Assembly 1.jpeg VFR Top Triple Iso 1.jpeg VFR Top Triple Iso 2.jpeg VFR Top Triple Iso 3.jpeg VFR Top Triple Iso 4.jpeg

-

From the album: VFR-RC51 Triple Clamps

-

From the album: VFR-RC51 Triple Clamps

-

From the album: VFR-RC51 Triple Clamps