gropula

-

Posts

127 -

Joined

-

Last visited

-

Days Won

4

Content Type

Forums

Profiles

Gallery

Blogs

Downloads

Events

Posts posted by gropula

-

-

A possible sign of tight normal valves is a loss of vacuum (assuming no vacuum leaks at the throttle body or hoses). It can be measured through the starter valve sync procedure.

I measured an increase in vacuum across all cylinders by doing the starter valve sync before and after the valve clearance adjustment.

This does make sense as the reduction in clearance increases the duration of the intake/exhaust opening and thus the overlap.

Service manual states that the vacuum should be 150-250 mmhg at the MAP sensor at idle. Assuming you're not at very high altitude, a reading close to 150 mmhg could indicate a loss of vacuum due to tight valve clearance on normal (non-VTEC) valves.

-

The fuel indicator isn't that accurate to be of any use. Track your fuel economy by fully filling the tank and write down the amount of fuel and mileage. I use autosist app to track fuel economy and service records.

My 2002 is tuned for power and response via rapid bike racing and wideband O2 sensor. I target 13.5 AFR at smaller throttle openings and 13.0 at higher throttle openings. My bike averages around 7.8L/100km with a very throttle happy hand and lots of VTEC. If I cruise sedately I can get around 7L/100 or better.

-

I used GT variant on my 6th gen for three years. I often ride two up with luggage. For camping trips my bike is overloaded, spec says 200kg max but we're probably 230kg together with the luggage. Stiffer spring and max preload helps keep the balance of the bike in check. With that amount of weight I'd like to be on the safer side as when I apply the throttle in 2nd gear the front lifts easily which means there's some 480kg on the rear wheel. Same for long uphils at speed. The rear tire probably begs for mercy when riding 100km/h on long uphill sections. Less flex from the stiffer sidewall means less heat which means less chance of failure.

I just had Dunlop Roadsmart 4 GT delivered. Haven't had them mounted yet. Interestingly, Dunlop's website recommends GT variant for the VFR. Their approach is different, they state that the GT variant has a profile which makes heavy bikes steer quicker, while the SP variant has a profile which offers better stability at high speed.

-

1

1

-

-

The one I bought had HA8098 written on the bag. Problem is, online retailers put generic pictures of either type with the same part number so I couldn't know which one I'll actually get. I waited for a new, sealed one to pop up on ebay with actual pictures of the product so I knew what I was going to get.

-

My bike had the smaller K&N when I bought it. I swapped to pipercross for a while, but then I found the big K&N so I bought that. The difference in the size of the filtration area is very big. The most important difference is that the smaller filter partially obstructs velocity stacks with the rubber part, which is very stupid.

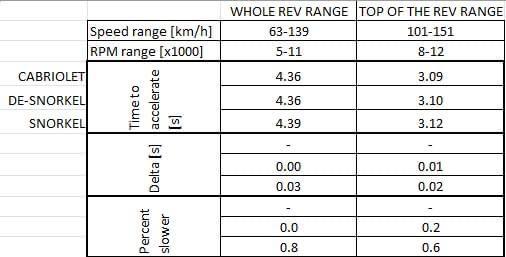

Then I tested the big K&N vs Pipercross by accelerating in 3rd gear on a flat piece of road, back and forth four times and then averaging the runs. I used a phone camera to video the tachometer and using video editing software I timed the each 1000 RPM segment, from 5000 to 11000 RPM. The K&N was slightly, but consistently faster, with a difference that equates around 1hp over the whole rev range.

The test could be improved by running in 4th gear, so the bike would accelerate slower and the differences would be more pronounced compared to the measurement resolution, but the runway would need to be much, much bigger as the 4th gear can take you up to 200 km/h.

-

1

1

-

-

You're right, I mistook the recessed pin for the protruding pin.

-

Are you sure you have oriented the the slide pin holder correctly inside the bucket (aka lifter)? In the image you posted the slide pin holder is upside down.

See the little nipple on the right side of the slide pin holder in image you posted? That protrusion should be oriented upwards, as the manual shows.

-

There's no way that's fuel coming out of the exhaust. It would be coughing fireballs or not running at all. Probably condensation.

Either way, have the injectors tested and ultrasonically cleaned in a specialized shop since you've got them out of the bike.

Ruptured fuel pressure regulator is easily diagnosed. If there's fuel in the FPR vacuum hose then the FPR has to be replaced. Otherwise it's fine.

-

No, but I've tested the removal of the snorkel and open top airbox at full throttle in 3rd gear. Snorkel removal gave a miniscule improvement with a nice bump in intake noise. Open top made no difference compared to removed snorkel but the intake roar was extreme. Absolutely deafening in VTEC even with earplugs in. I went back to the unmolested, snorkel-less airbox top.

-

2

2

-

-

I tested the double stack arrangement as a part of my variable velocity stacks project.

My testing showed that the gaps of 1cm and 2cm produce less overall power than no gap (basically a single long stack) and 3cm gap (basically a single short stack, the upper stack doesn't interfere with the airflow).

-

I agree with previous posts. Get sag right first. If needed change the spring rates to better suit your weight.

Lastly, jack up the rear to get better response. Dropping the front has the same effect but reduces ground clearance, although overall effect of dropping the front might be slightly more effective because the center of gravity ends up lower than if the rear is jacked up.

Putting a shim in-between the top of the shock and subframe is a simple and dirt cheap way to get the rear higher.

I really like the YSS shock I got on my 6th gen. The stiffer spring is better suited to my weight as I don't need as much preload to get right sag, while maxing out the preload enables the same sag while loaded to the max with passenger and luggage. The length adjustment at +5mm jacks up the rear a lot through leverage. Front end feel vastly improved, as is the initial turn in and changing of direction.

-

1

1

-

-

Hi! I have some oil leaks on my bike. I need some help on how to proceed.

In the photo there seem to be three places where the oil comes from. The water pump o-ring, the oil cooler hose (not actually sure) and where the oil cooler connects to the sump.

I removed the bracket that holds the overflow hoses when I was replacing the stator cover gasket to get easier access and clean the area. I probably caused the oil leak when I unbolted the bolt that holds the bracket and the oil cooler pipes.

The oil doesn't weep when the bike idles or revs lightly. It leaks while riding and it drips a bit on the floor after riding. There could be some coolant leak as well, hard to say as the coolant I'm using is red as is the oil. I use Motul 7100 and Mannol AF12+, supposedly safe for the water pump seals as the manufacturer says it doesn't contain silicates.

Replacing the water pump and oil lines is the obvious solution, it might be time to do it. It's a 2002 with 90k km (56k miles). What are your thoughts?

-

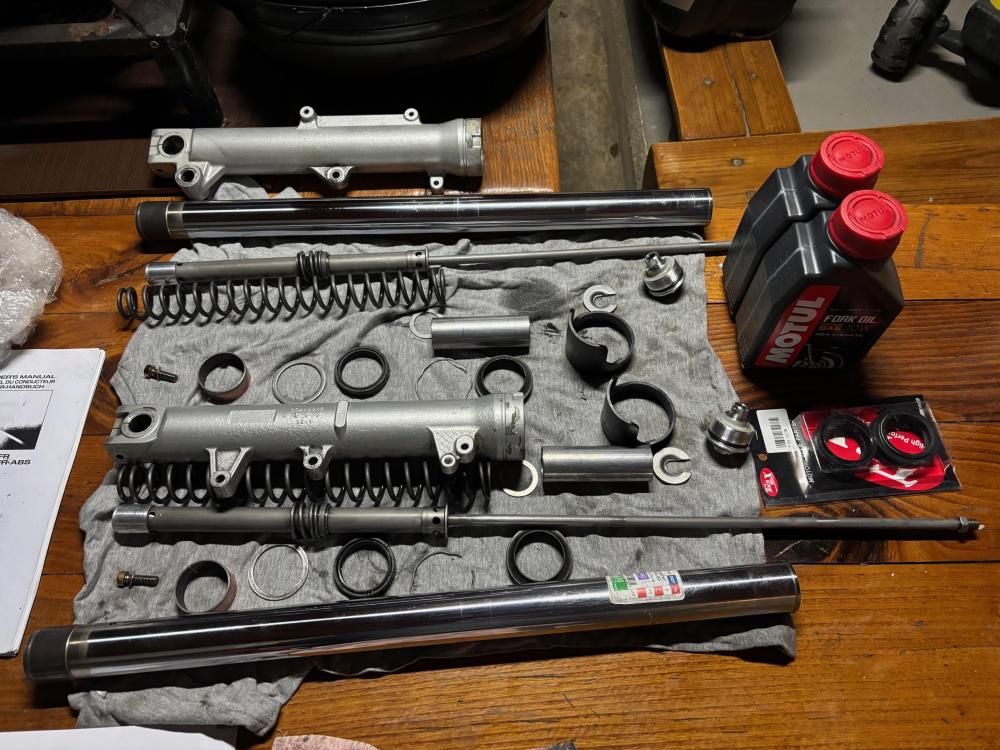

Used the winter months to replace fluids in my 02. Changed the engine oil and filter, fork oil, dust caps and oil seals, brake fluid and brake pads on the rear. Coolant is a year old so I skipped that.

Noticed the rear caliper wouldn't slide so I partially disassembled all calipers and cleaned and greased the slide pins.

Fixed an oil leak at the stator cover by replacing the gasket. Reused the gasket once before. Didn't hold for too long. Removing the old stuck on gasket was a faff. Stator still looks good.

-

3

3

-

-

How about just replacing the front ones? I don't care about the feel in the rear brake or the responsiveness of the combined portion of the breaking. I'd like to have a better feel in the front. I'm thinking of taking off the whole front brake line assembly and having a custom set made. All of the aftermarket sets are 8 hoses + 3 or split fittings at 700€ or something crazy like that. I believe I can have the front portion made in braided steel for much less, like 200 or less.

-

No, the sensor fails because of water condensing in the exhaust and a droplet falling onto the superheated sensor. It happened to me as well. I killed two widebands before I figured it out. I installed a timer relay which delays power for 4 minutes to the MTB module and o2 sensor. This way the exhaust has time to heat up and the water vapor stops condensing before the sensor starts heating up.

-

1

1

-

-

What I meant when I said add fuel to the cylinder is adding fuel manually to the fuel map of that particular cylinder and observe if the corresponding cylinder AFR richens up.

-

They are installed in a chained system. The individual my tuning modules have to be numbered ID-01, ID-02, ID-03 and ID-04. Stores who sell them stock and differentiate them. The SKU's are K27MYTB-01, K27MYTB-02 and so on.

I'm not sure if you're required to buy one of each or if they can be reprogramed or if they get the ID after connecting them in series.

I assume that the ID-01 should be installed in cyl no 1 bung. You can verify that this is correct by adding fuel to that cylinder and it should show richer mixture.

-

I agree with MBrane, I've removed the valve covers twice and reused the gaskets both times. I assume they were reused once before I got the bike judging by the excess sealant that was present. It was worth spending some time cleaning the old gasket as they're around 80€ for a pair. A very thin amount of black silicone carefully spread over the head and the cover was enough to seal the valve cover without any excess forming drops on the inside and risking clogging oil passages.

I recently replaced the stator cover gasket, it's a paper gasket that was around 10€. It was tough to remove the old one.

-

1

1

-

-

18 hours ago, Captain 80s said:

Would it matter? Perhaps it would move some secondary balance vibes to a different RPM?

I think it would create an imbalance in the primary forces as they're balanced out by the crankshaft counterweight. Since the piston and pin are the same weight it wouldn't be any different than before.

The secondary forces are dependent on the rod and piston weight only and they're partially canceled out because when one piston is at top or bottom the other is half way down the bore which creates two forces of equal magnitude but they're not directly opposed, but at a 90deg angle. This is why they only partially cancel out and why the ST1300 uses balance shafts to eliminate the vibrations entirely.

-

In this thesis you'll find the exhaust runner lengths and other valuable info.

-

It's not exactly known at which point the stock ECU engages closed loop mode because the ECU logic and maps inside it haven't been decoded. From experience and vague description by Honda we know it runs open loop when you vary the throttle position. When the throttle position is steady it enables closed loop. This is what I've seen on data logs from rapid bike. You can read about it in the official rapid bike thread, I've spammed the last few pages with my data logging, self tuning, autotune theories etc.

Also I think you're overcomplicating things. Straight forward and tested route is to use power commander or rapid bike. Rapid bike racing variant can adjust ignition timing as well.

To adjust VTEC transition point you can use a device that reads RPM and closes the 12V circuit to the VTEC solenoid. Some kind of RPM sensitive relay. I'm working on something similar to get my variable velocity stacks moving finally. It's a project that's been on hold for a long time...

Read about it in my variable velocity stacks thread. It has the same goal as v-boost in yamaha. Longer stacks with smaller diameter for mid range boost, short stacks with bigger diameter for top end boost. Having the throttle bodies work in unison like in v-boost is probably overkill.

-

Sheesh... Aren't there any better examples to be bought? I'd avoid such a bike, especially an '02.

I own a 2002 and I can tell you it's the worst vintage. The stator is too small, doesn't charge well at idle and low rpm. There were other minor issues as well which were fixed in 2003 and in 2006 the bike got a major update. I recommend an 06+ if it can be found in your area.

1. Stock injectors are fine if they're in good condition. Maybe they need cleaning. Flow rate is 320 cc/s if I remember correctly. Doesn't matter. No need to upgrade them because they're 12 hole injectors and you won't find anything substantially better for the power a stock bike makes.

2. The throttle bodies aren't interchangeable. Their main specs are the same so there's no difference between them in performance.

6. What piggyback unit are talking about here? I'm familiar with Power commander and Rapid bike. These are the two most popular solutions, and to be honest, probably the only two solutions. The bike runs open loop all the time, closed loop activates after you hold the throttle steady for a few seconds at cruise throttle openings (5-20% or something thereabouts).

7. Rapid bike racing is the only unit capable of advancing the timing. The map has up to 5 deg advanced timing in some cells. 1mm off the head will probably make the valves and pistons kiss or produce an extremely high compression ratio. 1mm sounds insane.

8. Honda did offer overbore pistons. Good luck with the rebore and replate and honing or whatever needs to be done. This isn't a cast iron bore. The bike uses aluminium cylinder sleeves with special plating on the cylinder walls.

9. KN and pipercross are good options. KN can be found in two different sizes. Bigger filter element provides better flow. The smaller one seems nonsensical. Had all three. Ultimately I chose the bigger KN type.

10. Flapper is a noise reduction device from what I can tell. It produces a Helmholtz resonance at 4000 revs from what I calculated. Can be disabled for more noise at sub 5200 RPM. Snorkel removal increases noise at all RPMs substantially. I tested the removal. Perfomance increase from removing the snorkel is around 1% so it could be testing variance. Pair is a different system. It injects fresh air to help catalytic converter burn harmful gases. It needs to be disabled to get accurate AFR readings. The flapper mod might introduce more air at low rpm and low throttle openings but nothing serious.

11. Stock exhaust is stainless steel already. Aftermarket lextek, black widow and delkevic are available. I'd avoid delkevic as it's collector looks horrible for flow.

12. At 28k km it's expected for the clearences to be okay. If you decide to check prepare for a lot of work. Shims are 7.48mm but only 8 valves use them. VTEC valves need a bucket replacement to adjust clearance. Only honda oem are available.

13. VTEC engages at 6800 in 2002-2005 but it should engage earlier, around 6400 as that's what 2006+ uses. You can't change when this happens because you can't change the mapping of the OEM ECU as it hasn't been decoded and nobody offers flashing support. You could theoretically make a piggyback that reads rpm and activates the VTEC solenoid at a different RPM but this hasn't been verified to work.

You will have a hard time extracting much more than 5-10 extra hp from this bike. I have all of the usual mods. KN filter, black widow headers, Leo Vince mufflers. I haven't dynoed my bike but this usually brings around 5-10 hp extra from the dyno data I've seen. Good luck.

-

1

1

-

-

I did a lot of research on this. I concluded that it's not good to have the stock o2 sensor plugged in. Check the rapid bike official thread where I explained my reasoning. Also, the autotune didn't work well for me. I was fiddling with it for a very, very long time and it always made the bike run worse and worse over time. I identified the problem and explained it in detail in the rapid bike thread. All I can say is don't trust the autotuner too much. I bought the blue bike addon and started logging my RPM, AFR and TPS values on my phone. Using the data I developed my own fuel map which works miles better than what autotuner did. It's not something I'd recommend though as it's a very long and involved process. Here's a pic of a wide open throttle pull AFR data with my map. The AFR is very close to target 13.2 with db killer in. I was testing the effects of having a db killer in, unexpected results but I won't comment much so I don't highjack the thread.

-

Start with cam chain tensioners. This will most likely solve the problem.

If at first the noise started when the bike is cold and went away once it's warmed up then it's 99% cam chain tensioners. If you leave it long enough it will develop into clattering all the time regardless of engine temp.

I replaced mine last week. 2nd set at 90k km. It's not hard but it's a bit cramped because the throttle body is in the way. Follow the service manual, but don't remove the throttle body because it's a lot of work and it can be done without removing them. Be very careful when removing the CCT so you don't drop the metalic cap into the engine. The CCT has a rubber head over which a metalic cap sits.

what have you done in the hope of increasing the powers

in Sixth Generation VFR's

Posted

Interesting development. Is the air fuel mixture tuned properly with the Power Commander 5?

With the amount of mods that you've done it's only possible to guess where things went wrong. Porting the cylinder head is very tricky and can easily be detrimental to performance if done wrong.