More Sound System Upgrades....mounting And Bringing Some Bling

After building my mini^3 amp, which I LOVE, I found I now needed a way to mount it. As I looked at my homebuild GPS/Camera mount, I discovered it would fit nicely in the space left between the mount and the support bar. I used some parts from my mad inventor kit (read pile of spare and odd parts) to make a dial I can twist to apply or release tension...a quick turn and the amp slides out to tuck away safely in my pocket or luggage. This also leaves the amp close to my Powerlet port or Tank Bag for charging, if needed.

I have found the amp last plenty long...about a week on a single charge with my ~1 hour commute time daily. I am going to build and sell the high-power version, this one is more than enough amp for me and I have an interested buyer for the other already, just got to get off my butt.

After finishing the amp, I realized I needed cables...especially one to go from the MP3 player to the amp. I had a couple pre-made interconnect mini to mini cables, but they were about 2 feet long:

and I needed more like 8 inches. I managed to swipe a cable that was a close fit from one of those Ipod/MP3 player speaker dock thingies...about a foot long, but it had 90 degree ends which is hard to find:

As usual, I wasn't content to leave it at that, so I decided I needed to make my own. Radio Shack didn't carry any of the parts I needed so I had to order some...like these connectors:

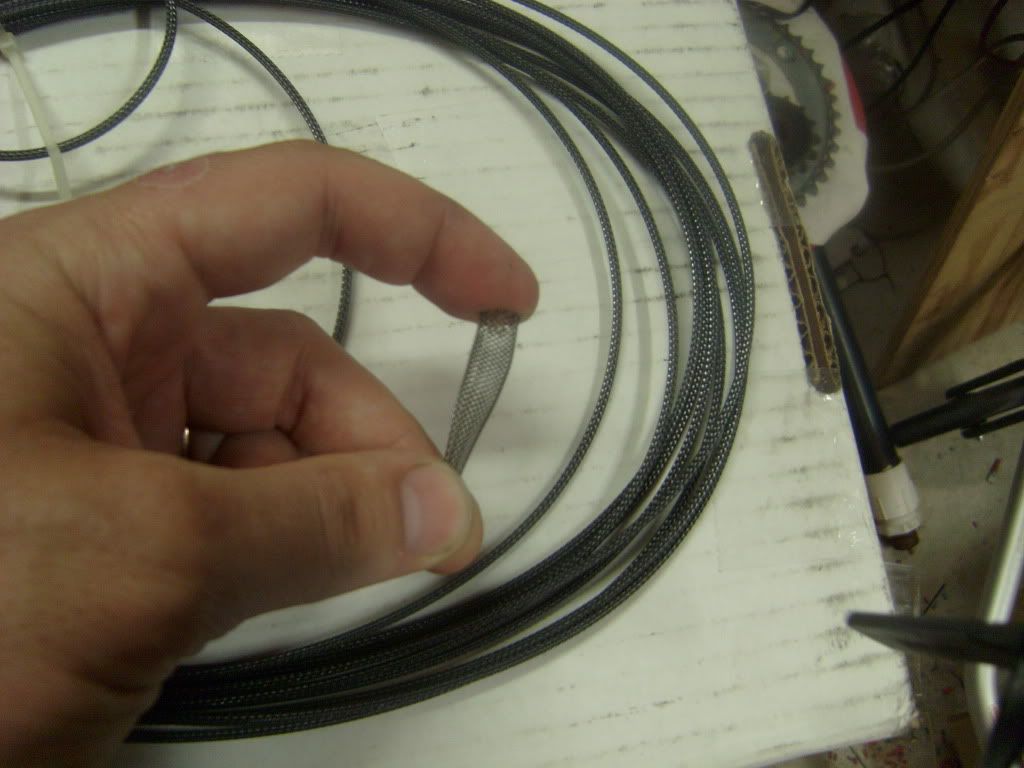

And this cable:

And some Techflex....very cool stuff. I like how when expanded the color of the cable shows through, gives it a nice tight look.

My first attempt was made prior to my cable arriving (I am not very patient). I used some Cat5 after reading about some other builders who had good luck with it. I would NOT suggest it. Cat5, at least the solid wire type, is much to inflexible for tight bends, and is a pain to work with as it breaks if you bend it a couple times. I ruined one connector on my first attempt, but managed to build a cable that looked ok...the Blue of the Cat5 wire shows nicely under the carbon Techflex:

After realizing that would never work, I waited for my cable to arrive. It did, and I preceeded to make another test cable, using some black with silver ends, covered with TechFlex:

I learned a good bit, and the cable looks pretty good, so I decided to try a 90 degree version. This was a bit harder dealing with the connector, but it turned out well. I used 2 layers of heat shrink for plenty of protection against kinking at the ends....not that it even bends with the way I have it mounted. I think it turned out well, and the red under the black looks good with the VFR!

0 Comments

Recommended Comments

There are no comments to display.