fallzboater

Member Contributer-

Posts

206 -

Joined

-

Last visited

About fallzboater

Contact Methods

-

Website URL

http://

-

ICQ

0

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

fallzboater's Achievements

-

Unchain My Bike... Or So I Thought...

fallzboater replied to BusyLittleShop's topic in Modifications

Isn't a tensioner required if the swingarm pivot and countershaft sprockets aren't on the same axis, anyway? With any kind of power, it seems like you couldn't allow much variation in belt tension due to swingarm movement. I suppose you might get away with it if the countershaft sprocket is quite close to the swingarm pivot, and in line with the swingarm near the center of travel. Even with my Hawk GT, when I added a longer rear shock, I also added a chain roller under swingarm pivot to help with the changes in chain tension due to the relatively higher pivot location. If your drawing is accurate, it'd be really easy to determine the change in distance between the sprockets through the range of travel by just drawing an arc. Have you done that? Weren't there some early reports of belt problems with the new Buell 1125? What was that about? Wider belt needed? :idea3: You could just buy a Buell. Better bike, anyway. :P -

My front brake mc (Brembo) has an integrated bleeder, but I have the bleeder banjos on both my clutch mc and slave. Anywhere that the banjo is at a high point, it makes things really easy. Mine, along with my custom-length lines, are from Galfer. These are not the same as speed-bleeders, which have a check valve. I suppose you might be able to use a speed-bleeder with a bleeder bango, but I use a Mity-Vac for a dry system, then the standard pump-and-turn method to finish off, works fine.

-

"Plate Flipper is intended for off road use only."

-

-

-

RAM mount with U-bolt around one of the grab handles is the way to go. Solid, position anywhere with a twist of the knob.

-

Lots of eye-candy there, thanks for the report. The funny thing is, with all the fancy CNC tools and dynos these guys have, most stock bikes have pretty crappy suspension setup and poorly matched springs for any weight rider. Even KTM bikes with WP forks and shocks, good quality stuff, but the OEM springs are all wrong and valving is quite poor. In my case, I'm lucky to have a guy a block away from me, working in his garage shop and no machine tools, that can work magic with the valves and shim stacks. It couldn't cost the manufacturers much more to get this right (or at least close) the first time.

-

-

Yeah, that was pretty much my understanding. Good for race wheels, generally not so good for the street. Race wheels are not expected to last over potholes, being run with a flat tire, etc. Infinite life of structural components is not necessarily expected, either. I've also read that Mag wheels have been banned in certain classes since if a tire blows, the rim scraping on the asphalt can start a fire which is difficult to extinguish. A real Cobra, sweet! Those wheels should probably have been removed and stored in sealed baggies with desiccant. I know you're supposed to insulate the Mag from the steel hub, with an aluminum or plastic spacer.

-

Oxidation, fatigue, or something else? I'm not aware of any reason that a mag part that's been protected on the shelf for many years would be any weaker than a new part of the same construction. What other metals are you thinking of? I doubt Ti is a good material for brake rotors, but it may be OK for a little-used rear brake. I've even heard of aluminum rear rotors being fit, but man, I bet you'd burn through them in a hurry. Here's some info from: Introduction to Gray Cast Iron Brake Rotor Metallurgy Mark Ihm, TRW Automotive Properties Desired for Brake Rotors • High strength and durability to sustain torque loads from braking • Stable mechanical and frictional properties through range of expected service temperatures • High wear resistance through range of expected service temperatures • High heat absorption capability to absorb braking energy • High thermal conductivity to transport frictional heat away from braking surfaces • High vibration damping capacity to minimize NVH issues • Minimal thermal expansion to minimize performance variability • High degree of corrosion resistance • Excellent machinability • Inexpensive material and processing costs

-

Excellent, let's ride! I'm off work on Friday if you're interested.

-

Looks great. When are you going to throw it back on the bike and come out for a ride? I did Lyle-Appleton-Klickitat-Glenwood-BZ Corner-White Salmon on Friday; roads are all in great shape. Cut the black vinyl into assorted size NACA duct shapes and apply liberally to all surfaces.

-

I'm not a fan of the two-cans-on-one-side look in general, since they end up looking too bulky. Those stubby Arrows look good, though. He should've used white zip ties on the frame. They're easier to find than black ones at the hardware store. I think it would look even better with the front fender painted to match. I've ended up with bare-carbon fenders on a couple of my bikes, and I've never been that crazy about them. I don't think I could stand white wheels. I think you'd be cleaning them constantly.

-

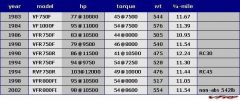

I liked the purple, but I'll be interested to see your "new" bike. Should look kewl. What are you doing with the wheels (please don't say chrome)? Teleskier's is the sweetest 5th gen I've seen so far; I hope you'll give him a run for his money. Does your dyno guy have the full Dynojet Tuning Link Center setup? My chipped and RSV-cammed Falco dynoed a bit rich last year, so I could probably gain a bit of power (and maybe better mileage) with a PCIII and the full meal deal.