-

Posts

662 -

Joined

-

Last visited

-

Days Won

43

Content Type

Forums

Profiles

Gallery

Blogs

Downloads

Events

Everything posted by sfdownhill

-

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Hi Dibbles - thanks for your interest mate. I sent you a PM and invited Duc2V4 to the conversation so we can hook you up. UPDATE - yes, it is definitely time for a header update. I wasn’t able to catch Wade before he lit out to go motocross sidecar racing this weekend - yes, he’s that crazy, but he is also a class champion in SoCal moto sidecars and knows his way around a racetrack. I will connect with him Monday to get a delivery date on the 15 sets of 5/6 gen headers that are currently in production. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

5/6 gen headers second production run update: Over the past week we have been speaking with Wade to determine a delivery date for the current order, which consists of thirteen 5/6 gen headers. We found out that, for several reasons not uncommon to small fabrication shops that do custom production work, he has not gotten our headers finished. We have a 'time to build' commitment from him that depends on further financial commitment on our part. We have communicated the specifics of this to each person who has placed a deposit for this production run of 5/6 gen headers. Bottom line - our confidence in Wade is not shaken, and we understand that - up to this point - he has been fronting all the material costs and all the labor costs of producing our headers, fully completing assembly while only receiving deposits that are less than 25% of the cost of headers. His position is that he simply needs more money up front to cover the costs of building 13 sets of headers. -

Unleashing Factory Power Stage II Tune! Special 8th Gen Edition

sfdownhill replied to Voided76's topic in Modifications

Voided 76, we took a vote and the outcome is that we’re using this photo of your gleaming pipes - including the crazy bird-carrying-bomb pillow - for all future marketing materials... -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Hello Header Community - I have two important updates on the header project. First I'd like to say thanks on behalf of Duc2V4 and myself to everyone who has participated in this adventure in any way. Fifteen months ago, all efforts to get a header built for the VFR800 had come to naught - even Duc2V4 and I had mostly given up after numerous rejections and lack of response from fabricators we had contacted. One year ago, a tiny flicker of hope sprang to life, the VFR community joined in, and now several dozen VFR owners have an honest-to-goodness performance exhaust solution. It has been awesome hearing from all the guys who have installed their headers and are laughing their butts off from 6000rpm to redline, me and Duc2V4 among them. This could not have happened without every one of you. We'd like to make three other shoutouts - we’ve mentioned these guys before, but thanks again to CornerCarver for loaning his Two Brothers headers so we could have Wade build a jig, thanks to Hammerdrill for lending us his 6 gen as a test/tune bike, and thanks to SamuelX for allowing us the use of his 8 gen for fitment and dyno testing. Update #1: We were sorting through our dwindling stock of Delkevic 42mm crush gaskets, separating them into groups of four, and noticed a couple of the gaskets [Five, actually] felt a little bigger to our hands than the rest. Putting the calipers on them revealed that the five crush gaskets in question measured 43.7mm in outside diameter. This is way too big to even begin to fit into the VFR800's exhaust port sleeve. *If you received crush gaskets from us and have not yet installed them, please give them a quick check to make sure they are the correct size, which is 41.6-41.8mm od. If you have gaskets whose od is greater than 42mm, please let us know, and we will replace them from our stock while we work out a refund/exchange with Delkevic. Update #2: We have been trying to make contact with Wade to find out where our next batch of 5/6 gen headers is in his pipeline, and finally got ahold of him today. We have a call with him scheduled for tomorrow and will post a further update as well as send PMs to all those who have deposits in for the current production run of 5/6 gen headers. Sorry for the delay. boldog új évet everyone! [Happy New Year in Hungarian] -

Unleashing Factory Power Stage II Tune! Special 8th Gen Edition

sfdownhill replied to Voided76's topic in Modifications

I’m on board w you and Duc2V4 on PMs now, Flya. Thanks -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Except the OEM single O2 sensor and bung on 8 gens - that has M12 threading VFRD new performance headers for 8 gens have one M12 bung so the OEM O2 sensor can still be used for more efficient closed loop operation during steady state cruising (highway operation). The M12 bung can be plugged if it is not being used. These headers for 8 gen also have a single M18/1.5 bung for wideband O2 sensors that facilitate auto tune (ie Rapid Bike, Power Commander, etc) and/or more accurate dyno tuning. -

Unleashing Factory Power Stage II Tune! Special 8th Gen Edition

sfdownhill replied to Voided76's topic in Modifications

Best looking set of pipes yet - go get ‘em Voided! We did our dyno work in Orange County with Attack Performance - they charge $125 for baseline, non-tuning runs. I will PM you with two local dyno shops I found in north San Diego county - both good guys with modest operations. Closer to you is Lee’s Cycles in San Diego proper, closer to Kearny Mesa. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Hi Drumagician, as Duc2V4 said, sorry for not reaponding sooner. I haven’t been getting vfrd updates properly, didn’t even get a notification of your post, so apologies there. Not to push the product, but if you want to do the performance header, you’ll be happier the whole way through your upgrade path and can line up a Power Commander or Rapid Bike, maybe even autotune or one of the maps we have for 5th, 6th, and 8th gens. Your bike will pull like you wouldn’t believe. Fun stuff. If you stick w the 1998 header, you will probably have an easier time fitting it to your 6 gen if you trim 5/8” - 3/4” off the collector exit. Or it might be better to trim the 5/8”-3/4” off the header end of your 6 gen midpipe. This trimming is what we have found gets the alignment of the 6 gen twin muffler assembly lined up w 5 gen headers. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Hi Wingate - and thanks Rush for helping fill in a couple blanks. Short version - we hope Rapid Bike autotune feature adapts to 8 gens the same way it adapts to 2000-2001 5 gens and all 6 gens - that RB leaves the single 12mm OEM O2 sensor on the 8 gen connected and employs a single added 18mm wideband O2 sensor to send air/fuel readings to the RB. This is what the headers are configured for. But we are not certain whether this is the case. Yet. We hope. We selected one 12mm bung so guys who bought the new headers could still use their single 12mm OEM O2 sensor. VFRD member Samuelx, owner of the 8 gen test bike, is using Power Commander 5 and has kept his OEM O2 sensor and all is well - no FI warning light or other flags. It is not an autotune system. On Samuelx's bike we were able to use the 18mm bung for Attack Performance's wideband sensor when the bike was on their dyno - this is more accurate than a 'sniffer' inserted into the tailpipe. We did have to purchase a 12" extension cable for the OEM O2 sensor to reach back to the new headers' collector exit, because placing the 12mm bung in the collector exit pushed it 12" further back than the front-of-catalytic-converter position of the OEM bung. This position allows air/fuel readings from all four cylinders combined. [The O2 sensor extension cable sells for $11 on ebay and is described as being for Honda Civic autos. Do NOT purchase the 12" O2 sensor extension cable for Acuras you might find on ebay, as it looks like it uses the same connector, but it does not. Ask me how I know]. We added the 18mm bung to 8 gen headers - also in the collector exit where it samples gases from all four cylinders - so that the wideband O2 sensor that Rush2112 described as a "single Rapidbike wide band O2 sensor" would function properly on 8 gen VFRs. We know the Rapid Bike autotune can use the third [wideband] sensor along with the two OEM sensors on 2000-2001 5 gen VFRs and all 6 gen VFRs [Duc2V4 is using this setup on both his 2001 and on his 2009]. After checking in with Duc2V4, neither of us are certain that one must use three sensors with a RB autotune on 5, 6, OR 8 gen VFRs. This is strictly a guess on my part, but it might be that RB sets up their autotune system to use the two OEM sensors on VFRs that have two OEM bungs/sensors simply because the two bungs are there, and they both happen to be full of sensors. I think I recall that with RB wideband sensors are an upgrade option, but OEM narrow band can be used - I could be wrong here. Duc2V4 can speak to this [And I hope he will - I'm floundering a bit]. What we hope for 8 gen owners who purchase new headers and are aiming for a RB with autotune is that RB sets up their system for 8 gen to use one 18mm wideband O2 sensor in conjunction with the single OEM sensor in the 12mm bung. [Please note the amount of restraint required to not add 'hole' after 'bung'] Since I'm listing and describing things I do not know, I'll add that I do not know if the the 8 gen's single 12mm OEM O2 sensor is wideband or narrow. The new performance 8 gen headers have an 18mm bung because 18mm is the size we know for certain that quality Bosch wideband O2 sensors come in; they are sold by both RB and Dynojet [Power Commander] and are used by most dyno tuning facilities. Bottom line - more research is needed. **Anyone who can help develop a definitive answer to how an 8 gen VFR implements a Rapid Bike autotune system, please do chime in here** -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Confirming what Duc2V4 said - the maps will be here and available on an ongoing basis. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

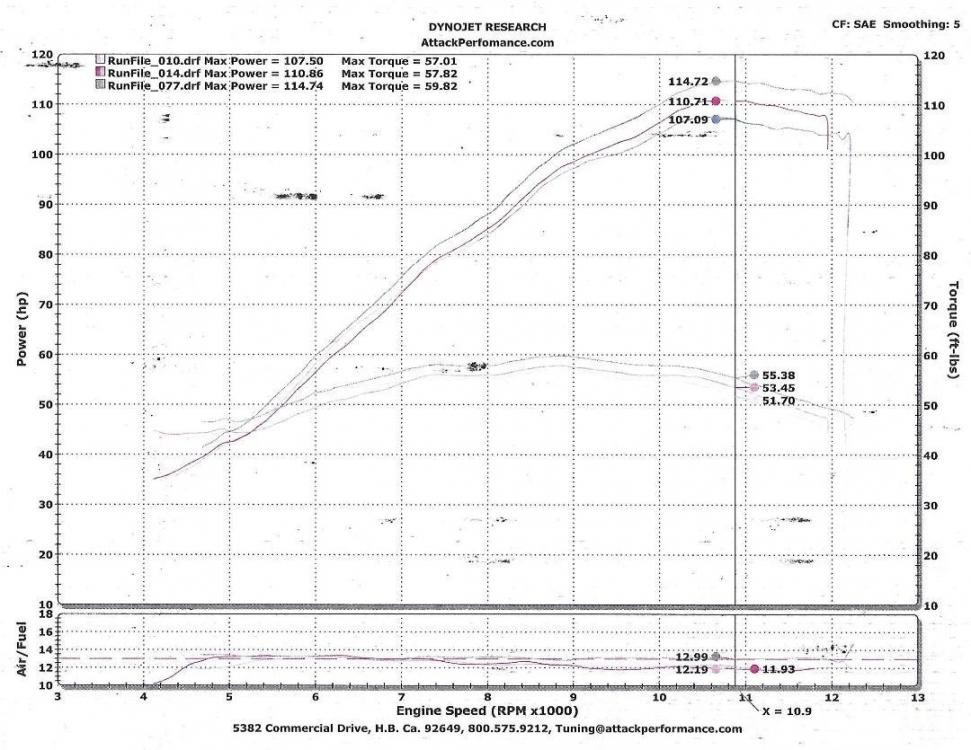

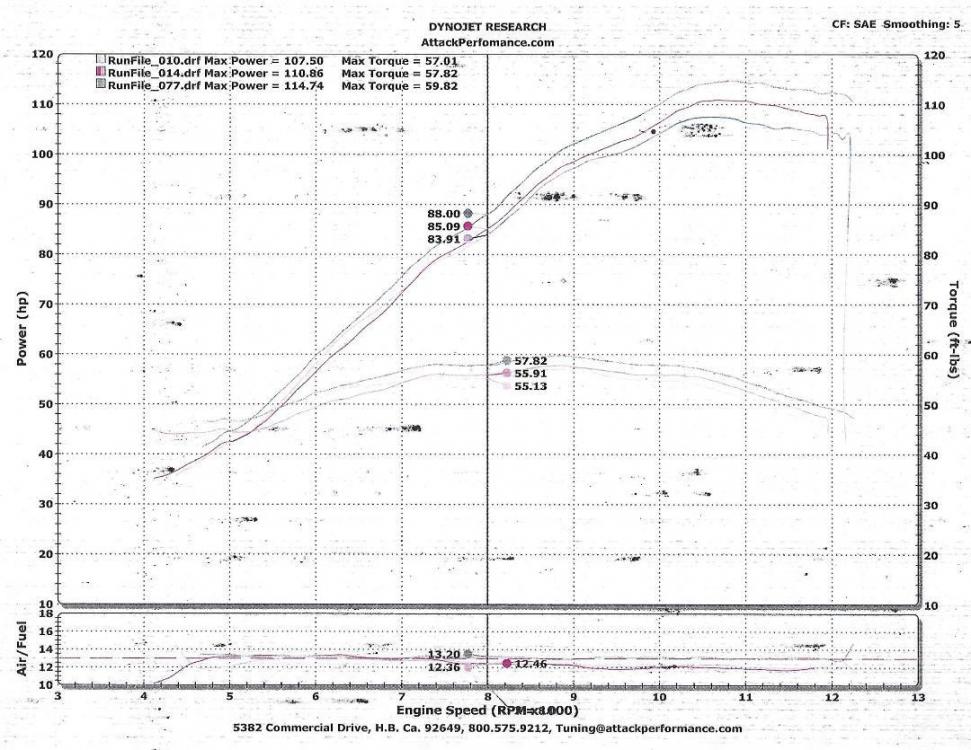

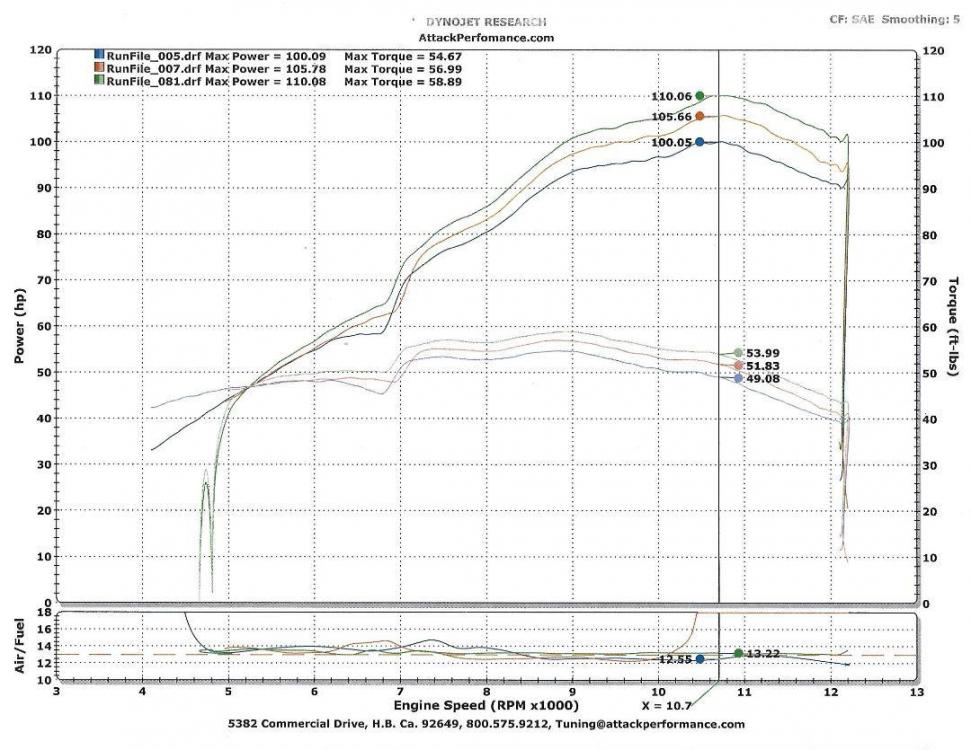

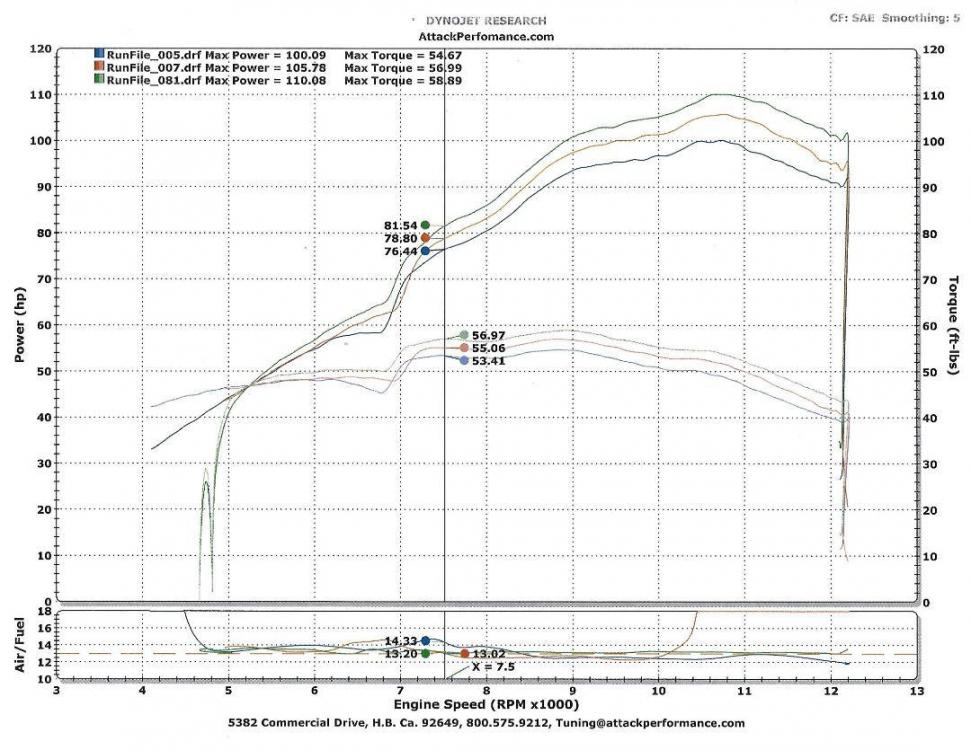

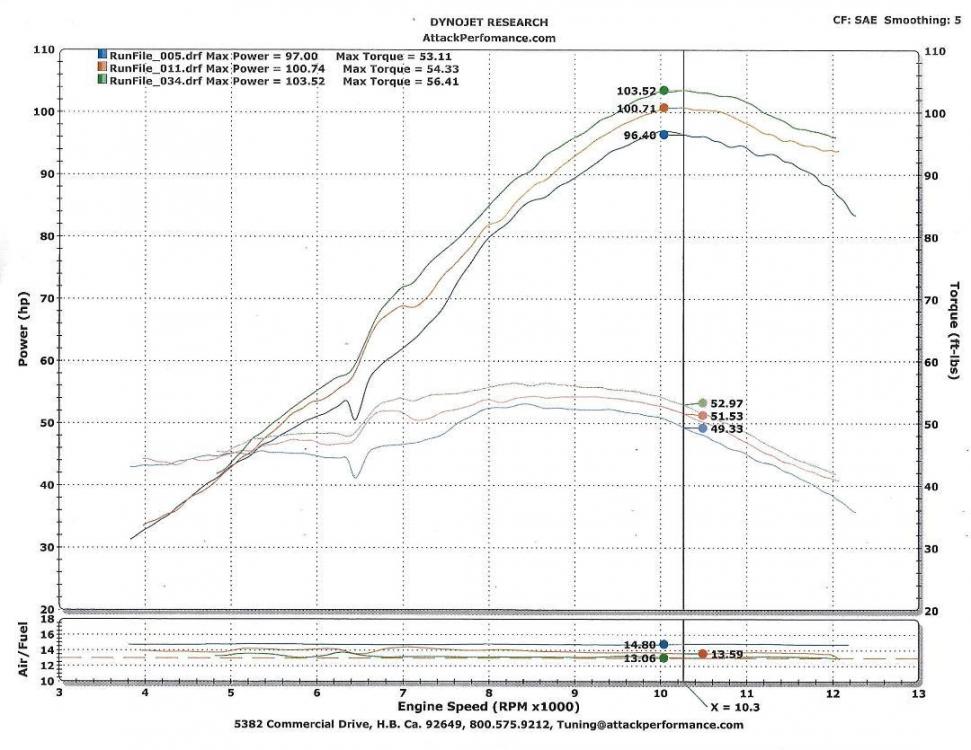

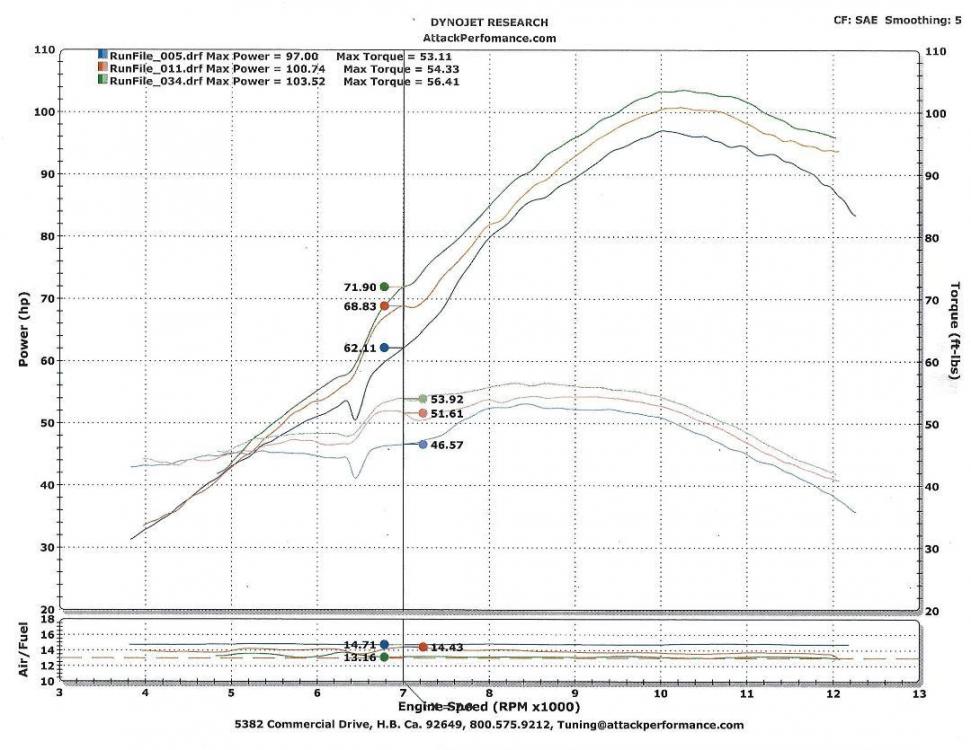

Jozef - our favorite dyno technician in the world and head of tuning at Attack Performance - has provided the maps he built on the dyno for: 5 gen VFR800 tuned with Power Commander 3 6 gen VFR800 tuned with Power Commander 5 8 gen VFR800 tuned with Power Commander 5 These maps will work well on any 5th, 6th, or 8th gen VFR800 with the new performance headers, a good quality hi-flow air filter [We prefer the K&N HA-8098 filter] and a good quality slipon muffler. If you have purchased these headers and would like to utilize one of these maps to optimize your VFR's performance without trucking it out to a dyno shop, we can email the map for your gen VFR to you for a donation of $50. Please send 'sending to a friend' to the paypal account of vfrheaders@gmail.com, and in the note section of the paypal transfer, specify the email address you'd like us to send the map to. Below are the dyno charts for the three maps. These maps were posted early on in this thread, but are included here to save people the trouble of locating them in the way-back portion of this thread. Each chart has three traces: [1] a baseline run with OEM headers [2] a run done with the new headers installed and a zero map, meaning no tuning and no changes to OEM ECU fueling were entered into the Power Commander map [3] a final run after a complete tune was performed There are two versions of each chart: [1] a chart with a reference line at peak horsepower/torque [2] the same chart with a reference line at midrange 7000rpm to demonstrate the midrange gains achieved with tuning the new headers [8 gen kicked butt at 7000rpm with 16% gains in both horsepower and torque] 5 gen Power Commander 3 map [peak]: 5 gen Power Commander 3 map [midrange]: 6 gen Power Commander 5 map [peak]: 6 gen Power Commander 5 map [midrange]: 8 gen Power Commander 5 map [peak]: 8 gen Power Commander 5 map [midrange]: -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

PM sent -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

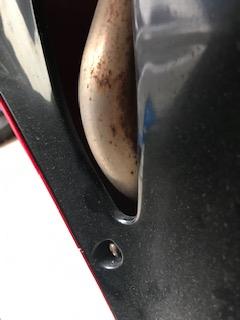

There has been progress. First please allow me to thank Duc2V4 for his patience and persistence in supporting and encouraging continued effort on this project - he is a rock star in many ways, more even than are evident in his high quality participation on VFRD. Second, please allow me to sincerely apologize to everyone - especially those who have placed deposits for headers - for not staying current with communication regarding this project. No excuse can suffice for me dropping the ball the way I have. I will be paying close attention, responding promptly, and doing my part from here on out, beginning with reading through/responding to all PMs and catching up on the many posts on this thread that I missed. We have been able to arrange with Wade, the fabricator of VFR headers, to complete construction of fifteen sets of 8 gen headers, in spite of not having met his minimum quantity of fifteen orders. These 8 gen systems have been built on a jig that was modified slightly to provide better fitment when the center stand is down. Seven of these fifteen 8 gen headers are already sold to VFRD members and to a couple others who placed deposits. Again, thank you all for your patience. Eight sets of these 8 gen headers are now available for purchase. Going forward, Wade has also finally agreed to build runs of as few as 6 sets of headers, down from a minimum order of 15 units. Because of this, those who have placed deposits for 5/6 gen headers in the second production run will be seeing their headers built soon. This also means a much shorter time between production runs for all headers, 5/6 gen and 8 gen. For upcoming 5/6 gen headers, Wade has modified the jig to provide better center stand clearance, as well as establishing clearance between the front right primary tube and the inner chin half cowl. Ten of the 8 gen headers that have been completed are currently at the passivators being acid dipped for strength and longevity. Passivation costs $90 per exhaust and has been discussed in detail early in this thread, starting with Sebspeed's querie on page 2: https://www.vfrdiscussion.com/index.php?/forums/topic/88463-new-5th6th8th-gen-performance-header-now-in-production-in-usa/page/2/] The five remaining 8 gen headers can be passivated if the buyers chooses to do so. To begin getting headers shipped out to their new owners, PMs with more detail will go out in the next 24 hours to all those who have placed deposits for 8 gen and 5/6 gen headers. We have also checked in with Tyga about their upcoming headers, and received an interesting reply. Here is the email exchange [with names and personal emails removed]: "> -----Original Message----- > From: ______ _______ [mailto:____________] > Sent: Friday, September 20, 2019 10:48 PM > To: Tyga-Performance <Tyga@Tyga-Performance.com> > Subject: Enquiry from TYGA-Performance: New Tyga headers for Honda VFR800 > > Hello, > > I just saw the Tyga update on the vfrdiscussion.com website - it is exciting to learn that Tyga will be producing headers and exhaust systems for the Honda VFR800. > > Are you far enough along in the process to have pricing for a set of headers for the VFR800? > > Which version or versions of the VFR800 are your headers going to be built for? 5th gen with two side-mounted radiators is 1998-2001, 6th gen with two side-mounted radiators is 2002-2013, and 8th gen with one front-mounted radiator is 2014-2016. > > Thank you very much for following through on this project. > > Best regards, > > ____________ > On Sep 22, 2019, at 9:29 PM, tyga <tyga@tyga-performance.com> wrote: > > Hi _________ > > Many thanks for the message. We are actually making the exhaust for the 1993-97 model. I am not sure if it will fit previous or subsequent models. I understand that the TBR one fits earlier models but not sure if they would be compatible with the 800. Our plan would be to get the 4th gen to market and see how they sell and hopefully, if it is successful, we can then adapt as necessary to fit earlier and or later models. Sorry, it looks like your wait will need to be a bit longer. > > Best regards > > Paul >" Postscript - we were able to work with VFRD member SamuelX and his beautiful 8 gen [Deluxe model] to develop this high mount exhaust to go with the headers. SamuelX wanted to keep his Yoshimura muffler, so we trimmed it to fit the bike's dimensions. I have had the privilege to ride this motorcycle on several of my favorite sets of twisted pavement. With the added performance, this bike was an awful lot of fun - thanks Samuel! For the first time, I starting thinking that perhaps the 5 gen is not the be-all, end-all of VFRs... -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Looks great capn. I never got to hear the Wolf with the new packing installed and quiet inserts removed - I bet with the TBR headers it is schweeet! Getting to have a listen to your bike is another reason for us to get out on a ride together. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

There has been a lot of activity since I was last staying up with events on this thread - all good stuff, even the teething problems. I sincerely apologize to everyone here for being off the reservation. I am currently in the high Colorado mountains and clinging to a one-bar signal that literally blows away when the wind moves. I will be back on reliable internet Monday and will thoroughly flesh out the points below. I have not been idle...Wade and I have been talking regularly about: (1) plans to finish the production run of 8 gen headers and sell from stock without waiting for 15 deposited orders. Wade is considering this. (2) modifying his jigs to move cylinder #1 primary 1/4” to the right, as there is slight interference with the center stand at the bottom of its arc. This occurs on my bike and the 8 gen w prototype headers, perhaps others? (3) gearing up further to do another run of 5/6 gen headers. On 5 and 6 gens cylinder 4 (front right) clearance with the inner half ‘chin’ cowl is a problem. The TBR headers get very very close at this point, and our production headers touch the chin cowl. Here are the TBR installed on a 5 gen: On my 5 gen heating the chin cowl with a heat gun and flexing it forward where the headers touch provided enough clearance to avoid melting plastic. The blue tape is how I marked the area to heat and flex: I just found out this internet connection can’t handle full res photos, so I’ll reduce the image sizes and insert then into this post as an edit later today. More to follow. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Hi eyrwbvfr - I've recently changed my subjective preference from new headers with no bungs and PC3 on a 2000-2001 VFR to one bung in the collector exit and PC3. I changed my mind when Jozef - the dyno tech at Attack Performance - was pleased to find an 18mm bung in the collector exit of the 8 gen test headers. He gets more accurate readings from his Bosch wide band sensor inserted into a bung in the collector exit than he does with a 'sniffer' inserted down the tailpipe. A number of VFRD and VFRW members with 2000-2001s are getting good results with PC3, and some are happy with Rapid Bike fuel management systems. You may have read other posts in this thread that document the problems the 2000-2001s have with PCV - stay away from that device. An option would be to plan on headers with one bung for dyno tuning and obtain Dynojet O2 Optimizers to plug into your VFR's wire harness where the O2 sensors used to connect. There is a dyno chart earlier in this thread that has three graphs that pertain to your question: one graph line for baseline stock 5 gen, one with the headers installed but a zero map on the PC3 [zero map means the PC3 makes no changes to OEM fueling], and the third graph on the chart representing the headers with a custom tune done on the PC3. The timing for the next production run of 5/6 gen headers depends on when we gather an order for 15 units or more. A rough estimate for delivery of the next group of 5/6 gen headers is 10 weeks from now. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Thanks for the generous offer, Dennis. We were able to put together a 6 gen slipon muffler assembly and test the headers with it. I bet your pipes sound better, though. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Man, the folks on this forum come up with some of the coolest ideas! carlgustav, that perf metal is brilliant for prototyping - bends as easy as cardboard, but stays bent. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Thanks! It's super cool of you to consider loaning us a set of pipes as nice as your Leos. We did manage to get the 6 gen onto the dyno, and the associated muffler project was a trip which will be detailed in a separate thread soon. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Here are a few notes spawned by MooseMoose's awesome, informative, and more than a little amusing installation thread. If you purchased headers, or think you might, or think you might ever install a set of any headers in your life, you can find MooseMoose's thread here: And this is a bit of extension/extrapolation on his findings: +1, +2, +3 on all the compliments for MooseMoose's detailed documentation of his header install odyssey! Great work, and thanks to him for all the extra time he put into sharing so much pertinent information with the community. Here are a couple observations/additions that occurred while reading his thread: - Header stud nuts, torque, and anti-seize Confirmed: 9ft-lbs is more than enough to hold things together ESPECIALLY if using anti-seize. I bent flanges on the prototype headers when I used anti-seize and torqued the nuts to 9 ft-lbs. I suspect that at 9ft-lbs, the lubrication component of the anti-seize allows greater force to be exerted than 9ft-lbs on 'dry' threads with no anti-seize. I have chosen to wipe the anti-seize from the studs' threads on the 4 VFRs I've been using for the header project. I say 'wipe off' because I just remove what will come off with a rag and do not clean with any cleaner or solvent. Who knows, there might be enough residual a-seize left to do just enough good. CAUTION 6 GEN OWNERS: in the list of torque values on page 2-3 of the 6 gen service manual, Honda states 'exhaust pipe flange nut' 15 ft-lbs. This is NOT the nut NOR the torque value of the header stud nuts we use to hold our headers to our heads. That sounded weird, but this problem with Japanese-to-English translation has caused one owner of new headers to overtorque the header stud nuts. Thankfully, no damage occurred. Honda calls the header stud nuts 'Special Nuts', which sounds like a breakfast cereal one would eat while listening to MooseMoose's fictional band 'Overtorqued Nuts'. [Actually Honda calls them 'exhaust pipe joint special nuts' and specifies their torque value at the aforementioned 9ft-lbs] Later in section 2 of the 6 gen manual the exhaust component torque values shown on the drawings are correct. Be patient with the special nuts. As MooseMoose suggests, make circuits around all the nuts starting when they are all just finger tight. I've had 9-10 shots at removing and installing headers recently, and this procedure works best for me: Once all 8 nuts are finger tight using a socket on extensions but no wrench, go through all 8 nuts in a circuit around the bike, adding 1/2 turn of tension. This takes a fair amount of time, but keeps all the exhaust components gently easing together into their happiest states. As soon as a 1/2 turn begins to require more tension - this will happen on one or two nuts before it happens on the others - switch to the torque wrench and set it at 5 ft-lbs. Go around another circuit of all 8 nuts, adding another 1/2 turn only where necessary until all 8 nuts reach 5 ft-lbs. Change the torque wrench setting to 6 ft-lbs and go around again, taking each nut up to 6 ft-lbs. Change the wrench's setting to 7 ft-lbs, rinse and repeat. On both 5 gen test bikes, going from 7 ft-lbs to 8 ft-lbs required only a tiny bit of wrench rotation, and going from 8 ft-lbs to 9 didn't produce any movement at all - I believe this is because the nuts were tight enough at 8 ft-lbs, and probably would have been safely secure at 7 ft-lbs. On the 8 gen test bike, the nuts stopped moving at 8 ft-lbs instead of 7 ft-lbs. Wade laughs at me when I crawl around the perimeter of a VFR with a torque wrench, carefully setting each nut. He says "Just tighten 'em until they stop crushing the gasket!". I guess with as much experience as he has, he can confidently 'feel' when the gasket stops crushing. I've chosen to stay with the torque wrench...it is my friend. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Yep, that's originally why I wanted to coat them. Vanity. Pure vanity. And that is the rub - a question that was brought up is "How does a professional applicator effectively coat the insides of multiple, connected bendy tubes?" Answer: A coating company Duc2V4 told me about [Thank you Duc2V4] has devised a simple method of coating the inside of headers. This is so simple and of such quality that at first I thought the idea must have come from Mohawk. They plug the ends of the headers and pour the tubes full of the same ceramic coating that they apply to the tops of pistons, then they pour out the excess material before curing the headers. And yes, standard ceramic coating on the outside of headers is thin...so thin that it is described as mechanically delicate [scratches easily]. The coating place also explained that different colors of the same ceramic coating product have different mechanical strengths - silver is toughest and most scratch resistant, black is weakest and scratches easiest, titanium [the color, not the metal] is somewhere in between, but closer to silver in strength. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Hey Nick - sounds good. Sorry to have taken so long to reply - I've been neglectful due to needing to get caught up with the day job and real life. A few guys have placed deposits on 5/6 gen headers for the 3rd production run, so that will be the next undertaking after the 8 gens get finished. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

6 gen headers have had 5/8" cut off the collector exit, so it may very well be possible to slip the headers on over an installed center stand. The three-point fastening of the 6 gen muffler system won't fit correctly with the stock 5 gen collector length. If you've ever wrestled a set of 6 gen mufflers onto a set of 98/99 OEM headers, you know exactly what I'm describing. -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

Best, simplest idea yet. And it wouldn't have to hang a single thing on the 6 gen midpipe. 5 GEN RIGHT SIDE CENTER STAND BOLT IS REGULAR RIGHT HAND THREAD HighSideNZ - you are correct about 6 gen 8 GEN RIGHT SIDE CENTER STAND BOLT IS REVERSE LEFT HAND THREAD [Recent experience with dyno test bike] -

New 5th/6th/8th gen performance header now in production in USA

sfdownhill replied to sfdownhill's topic in Exhaust Systems

I hear you, Marv! All my dreams of modifications/upgrades are temporarily on hold too. What gen VFR do you have? 8 gen headers are gathering orders for the next production run, probably 8 weeks to completion. After that, we’ll start another run of 5/6 gen headers, so somewhere along the line, headers will probably line up for you.