-

Posts

3,812 -

Joined

-

Last visited

-

Days Won

117

Content Type

Forums

Profiles

Gallery

Blogs

Downloads

Events

Everything posted by Grum

-

No doesn't need "resetting". Info... 1. With the Sidestand down Ignition to On, Kill switch to RUN any active fault code will be displayed. 2. When riding, if an active fault is detected, your Fi will illuminate full On but will not flash a code (Honda logic is not to have distracting flashing lights while riding). Only displayed as per 1. 3. Resetting you refer to is the method of erasing historical stored codes. These could be codes like the MAP or IAT sensors disconnected during the SV synch or genuine past stored faults that have since been rectified.

-

Just my two cents worth, I hope others with more experience in this area might chime in. Interesting question. SV synch is fundamental to good even idle, and smoothness in the small throttle opening zone, a mechanical setting, adjusted at normal operating temp, without the influence of the fast idle Wax Unit, and butterflies closed. Stands to reason this should be carried out first along with correct warm idle adjustment of 1200rpm. Assuming badly balanced SV's, and especially during the cold start enrichment phase, a slight touch of the throttle opening and the added air might cause a stall. I know of a similar effect (possibly in both hot and cold modes) on a 5gen. a faulty signal from the TPS at low throttle was measured, but not bad enough to force an Fi DTC. The whole throttle body was replaced and problem solved. All warm engine ops are normal according to Shane the OP. Perhaps signals from MAP and/or ECT are marginal at cold temps and might need checking. Watching the Wax unit action on the Starter Valves, and if the movement is smooth and gradual from cold fast idle to the warm Idle, you can then discount the Wax Unit causing any problems.

-

Strange sound when engine is hot and fuel tank cap is closed

Grum replied to klebocna101's topic in Maintenance Questions

-

Hey D, so what's been happening with you?

Grum replied to Duc2V4's topic in OTHER Motorcycle Talk (non vfr)

Great news Duc. Speedy recovery. I fully understand the frustration from post operative blues of not being able to ride for lengthy periods. Nice partnership with your mate, rider training in exchange for bike help. I find it one of the joys of motorcycling, always learning and refining technique and smoothness, whether or not I achieve my goal is debatable! Great motorcycle porn shots! Guess you'd never want a faulty "trigger finger" with a six shooter in your hand! Take care and best regards. -

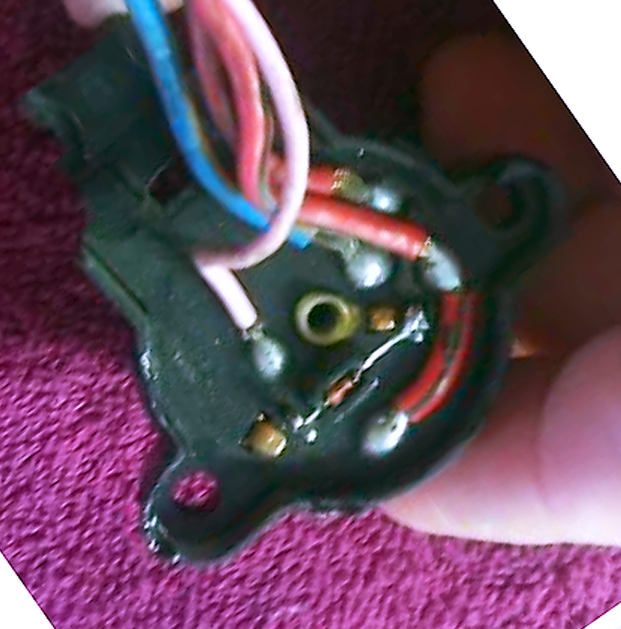

Oh dear! I feel your pain, sounds like you've done a lot of guessing and not much measuring, at least you have some good spares! Such a shame you tossed the Ignition Switch. As far as I know that zener diode security function wasn't on Australian bikes. Either our American friends might be able to advise on a replacement, Or a bit of clever wiring to the standard three wire switch adding the appropriate 3.9v zener diode to the Pink wire and other end to the Red/black IG 12v Switched wire(zener diode polarity needs to be correct). As mentioned you need to get 9v on the Pink wire to enable the ECM. See attached. Get some advice from a good Technician on the best way to do this if you are unsure. The symptoms for this device Not working is - Fi Light fully On, and No Fuel Pump prime. Good luck.

-

Strange sound when engine is hot and fuel tank cap is closed

Grum replied to klebocna101's topic in Maintenance Questions

You may Sir........ Copied this info from the 8gen. posting "Vent System - Update" from 2021. Assume the VFR800X has the same filler cap and vent system. Beware the tank vent hose! Pressure Relief - The common noise we all have heard, and as one member puts it "sounds like the Fuel Pump is priming with power off" or just a few second buzz, fluttering or gurgling sound. This is coming from the Pressure Relief Valve in the filler cap as the tank pressure builds and overcomes the spring tension on its valve. This process will continue to repeat any time slight positive pressure builds in the tank. As you stop a warm engine the heat transfer to the tank causes this to happen more frequently and if you open the filler cap in between the venting you'll always get a very slight pressure relief. Vacuum Relief - Negative Pressure relief also has to overcome slight valve spring pressure as the fuel level drops while riding. On cold days when topping up your tank you may notice very slight suction as you open the tank cap. So depending on temperatures and riding conditions it is Normal to have either slight Vacuum OR slight Pressure as you open the cap. The emphases being SLIGHT. Blocked, Kinked or crushed Breather Hose = DANGER! The problem with the 8gen is the first 12 inches or so of small diameter breather hose. When the Fuel Tank is raised to the maintenance position, the hose is pulled up through a lot of piping and general clutter in this area. If this hose is not manually pulled outwards at the small to large hose coupling taking up the slack as the tank is lowered, you run the chance of a blocked kinked breather hose. The nasty effects of a blocked breather cannot be overstated on these bikes! - Strong Vacuum, can make it impossible to open your filler cap. The Fuel Pump has enough strength in increasing the vacuum while riding to physically damaging your tank, bending the sides inwards. - Whilst having the bike in the sun strong positive pressure can distort the underneath of the tank deforming it outwards. Or virtually blasting the filler cap open as you unlock it. Any signs of strong pressures, negative or positive when opening the filler cap is a warning to check the breather hose. -

All done. PM replied.

-

Doesn't the barrel of the switch separate from the wired base? Couldn't a locksmith help you out, I'm sure they could fish the broken key from your original? Yes, anti theft function, if you have the Pink wire and zener diode this sends 9v to the ECM to enable it, 12v or Zero = Dead ECM.

-

Hi M8. I definitely do but it's a 13meg .jpg file. I thought I uploaded it to the forum a few years ago can't find it. Tried to attach to this but file too big Using photoshop elements I managed to splice together a number of sections of drawings creating a nice hi res complete color drawing. Can you PM me an email address? Think email will cope with up to 20meg

-

No mate not normal. "I did what you said." Excellent, I'm glad the FPR wasn't leaking! Have a close check of all the Throttle Body vacuum hoses, look for any small cracks or damage, especially make sure All the hoses for the MAP sensor are good. - Any Fi fault codes? - How old are the Spark Plugs? - What fuel is currently in the tank? Octane, Ethanol level and how old?

-

Wow, nearly 236,000 faultless kilometres, great testament to Honda reliability, nice looking bike. Hope the 1200 lives up to the enjoyment and durability you've had with the NC700X. Sure hope my 2014 8gen VFR can live up to that mileage - I have no future replacement plans for my VFR, now at over 96,000kms. Cheers

-

Sounds like you might have a bit of stiction with the Wax unit linkages, etc. Try cleaning and lubricating all linkages, a spray of some WD-40. See if that makes any difference. You might also benefit from a Starter Valve Synch procedure. While you're in that area. Pop the vacuum hose off the FPR Fuel Pressure Regulator, check the hose is dry and no weeping of fuel from the FPR vac hose fitting. Weeping fuel = Ruptured diaphragm. And.......Download the Service Manual from the forum if you don't already have it.

-

Some good voltage checks especially around the ESR, voltage on fuse test points Ignition On and Off, visual inspections for strange wiring, continuity check of Ignition Switch function. Are all good starting points. Download the Service Manual form the forum if you don't have it. May the Force be With You....There's plenty of info to get the ball rolling, very interested in what you may discover, post photos. Strangest VFR fault I've ever heard of!

-

Can you unplug the R/R run the engine, is there any change to the Ignition Switch operation? Grasping at straws a little now. - Suggest accessing the Ignition Switch 4P plug and do some continuity checks confirming good Switch operation. Refer bottom left corner of wiring diagram for Switch Connection Table. I'm struggling to relate your symptoms to the wiring diagram, also struggling with what or how a wiring modification could induce such strange issues with two separate switch functions.

-

Bloody hell! Now I'm really confused, this is crazy. Check for Non OEM wiring. Are you able to get any feedback from the previous owner as to wiring changes or anything done electrically to the bike?

-

RIGHT - This explains part of the Fault. The Ignition Switch is faulty or you have a Red wire to Red/Black wire short, powering Fuses C,D,E, and F. Refer Ignition Switch wiring on previous diagram. But how on earth does activating the Kill Switch then turn Off power to these circuits?? Strange wiring modifications maybe. Important now to check all voltages at the ESR with Ignition ON/OFF and Kill switch 12v Power to ESR Black wire. Note - Engine can Only continue to Run if 12v Power on the all important EFI power wire being the Black/White from the ESR is there when it shouldn't be. eg When Kill Switch activated or Ignition to OFF.

-

Never been an issue with all 4 VFR800's I've owned with after market exhausts fitted, 1200 shouldn't be any different. O2 sensors means ECU runs in closed loop, so air to fuel ratio is continuously optimized. Think you're worrying about nothing. I'd probably go back to the OEM type airfilter if it was mine! Good Luck with the bike, take it for a good test ride. Check it's maintenance history. Coolant change, brake and clutch fluid replacement - should have had a few of those! Oil and filter, etc. P.s. I'm sure there was a rear wheel drive unit issue recall for the early 1200's. Make sure this has been done.

-

That's one good thing, the Kill Switch when activated does inhibit Cranking. "When kill switch is in the Off position the engine does not crank" - Sorry to be pedantic assume you Did have Ignition to ON when checking this? - Very Important for diagnosis, Please Check exactly this - Ignition ON, Kill Switch OFF, Press Starter Switch - Does the engine Crank ? Absolutely completely wrong that either Kill OR Ignition Switch doesn't stop the engine. HISS cannot cause the condition you have. Crazy to think a dealership would say such a thing! Questions.. - With the Engine Running. Then turn Off only the Ignition Switch (assume the engine continues to run). Do the Headlights go Off and the Instrument Panel go blank? - And with engine running, Sidestand Down, Clutch In shift to in Gear. Does the Engine immediately Stop as it should? - Can you identify any strange non OEM looking wiring anywhere on the bike, you'll need to remove a lot of plastic to check this? As possibly only a part of the fault. I'd be checking to see if the Bank Angle Sensor has been bypassed. Meaning its unplugged and the Red/Yellow wire is jumpered to the Green wire. Or the Red/Yellow wire simply Grounded. I think the bottom line here (at this stage!) is that the ESR is possibly staying energised when it obviously shouldn't. Hopefully!! a few voltage checks might find out Why.

-

Wow very strange. Strong suspicion of modified wiring or possible wiring short 12v to 12v. Never heard of this one before. Has this anomaly been there since you picked it up 3 weeks ago or only just happened? This could potentially be a warranty issue if purchased from a dealership. You have a strong case here, you have an incorrect and potentially dangerous situation. Kill Switch has two functions when in the Kill position. 1. Engine Stop Relay coil 12v is removed Black wire = Dead Engine. 2. Removes 12v Starter Relay coil voltage on the Yellow/Red wire = Starter will not Crank over the engine. Question - Can you crank the Engine with the Kill Switch NOT in the RUN position, it shouldn't crank? Ignition Switch to Off Kills power to sub Fuses C, E and F refer the attached drawing ( 2005 model should be similar to yours). Loss of power to fuse C being the 12v power to the Kill Switch and the Bank Angle Sensor also knocks out the Engine Stop Relay to kill the Engine. Engine Stop Relay is not being controlled properly by the sound of things. Have you got the Service Manual? You can download it from this forum. Do you have a multimeter? If Yes then... Suggest you follow the Kill Switch power path...refer attached wiring diagram. 1. Measure Voltage at the Engine Stop Relay on the Black wire there should ONLY be 12v on this wire when Kill Switch is in RUN position with Ignition to On. Activate the Kill switch a few times while monitoring the voltage. It might be easier to monitor this voltage at the 18P Blue connector located just forward above the L/H radiator, remove the left side cowl. What do you measure every time you operate the Kill Switch?

-

I'm amazed at the engineering of this project, kudos to the OP. But with all the added hp of a Supercharger surely wouldn't every component within the engine, pistons, crank, transmission, clutch etc potentially be stressed beyond its design capability? Just wondering!

-

Just for a laugh!..... 1972 - Yikes, 52 years ago!! My beloved Honda SL100, absolutely had a hoot with this bike. Worked three paper delivery rounds per week to save up for it. I'd really give this bike a work out and never had a fault with it. That bike won me over forever with Honda's build quality, reliability and durability. My buddies little Honda Mini Trail was also bulletproof. ATGATT...only partially back then. Cheers

-

Just to be clear.... 1 - Was a blown Main Fuse 30amp in the Starter Relay the cause of the bike dying on your short day trip? OR has the fuse issue Only happened since the wiring change? 2 - And with the R/R unplugged. It still blows the fuse Only when pressing the Starter button? 3 - Your are absolutely sure, this fuse Only blows when pressing the Starter button, and Not just with turning the Ignition Switch to On? 4 - Assume the replacement fuse is a 30amp Fuse? Sorry, but need to be sure! 5 - Do you have photos or wiring diagram of the changes you've made? My gut feeling at this stage is there's something strange going on within the Starter Relay when being energised. Independent checks on the Relay can be run after hearing back regards questions above.

-

Hi Mello. Thanks for the info. Saw his name on the member list. I don't want to join the ST-owners forum, but if you're on it? Can you send him a PM, tell him to get back to the real forum! VFRD misses him. Cheers

-

We're not done just yet. 1 - Ok. So I get from what you're saying. You still do not hear the Fuel Pump prime at switch on? 2 - Can you elaborate as to what isn't plugged in? Apart from the obvious light's. "the fuel pump runs continuously with the plug bridged. (didn’t hook up fuel line since it was just a test for the pump. could be why it’s running continuously. not sure.)" That's exactly what should happen when bypassing the FCR! Fuel Pump runs continuously. 3 - Verify good continuity of the Brown/Black wire(FCR control wire) from the FCR to A21 (or possibly B18?) at the ECM. Here's a test for the ECM and Fi Light. Refer to chapter 5 in the Service Manual pages 5-7 to 5-8. 4 - Add a shorting link to the the ECM Service Check Connector as if you wanted to retrieve any historical Fault Codes. With Sidestand down and kill switch to RUN. Switch On Ignition. Does the Fi Light come On or flash a code? It should do one or the other. 5 - Looking at your photo again and seeing the ECM exposed as it is. Do a close inspection for any impact damage, are there any physical signs of cracks, on the ECM or its connectors? 6 - Check the wiring of the Ignition Switch. Does it have a pink wire and a diode mounted on the underneath of the switch like the photo attached? This diode and wire performs an ECM enabled and security function. 7 - And one Final Test, the end is near! Voltages measurement, Red meter lead to Battery Positive. Black lead to the Brown/Black wire for the FCR. Everything plugged in. Kill Switch to RUN, with Ignition to On, DO YOU MEASURE 12V FOR APPROXIMATELY 2 TO 3 SECONDS AT SWITCH ON? Let's know how you get on with the above questions and tests. All 7 of them Please! This should determine if you do have a dud ECM.

-

Good report again Kyle. Hmmm getting tricky! Can you just re-confirm that - with everything plugged back in, at switch On, Kill switch to RUN, do you at least hear the Fuel Pump prime/run for 2 to 3secs? If not, just for the hell of it swap the FCR with your Hi Beam Relay, does this change things? Fi Light - Do a continuity check of the White/Blue wire from the Instrument Panel to (possibly!) A20 at the ECM. Refer above wiring diagram.