I am in deep now!

OMG I am in deep now everytime I take somthing off I find somthing else wrong

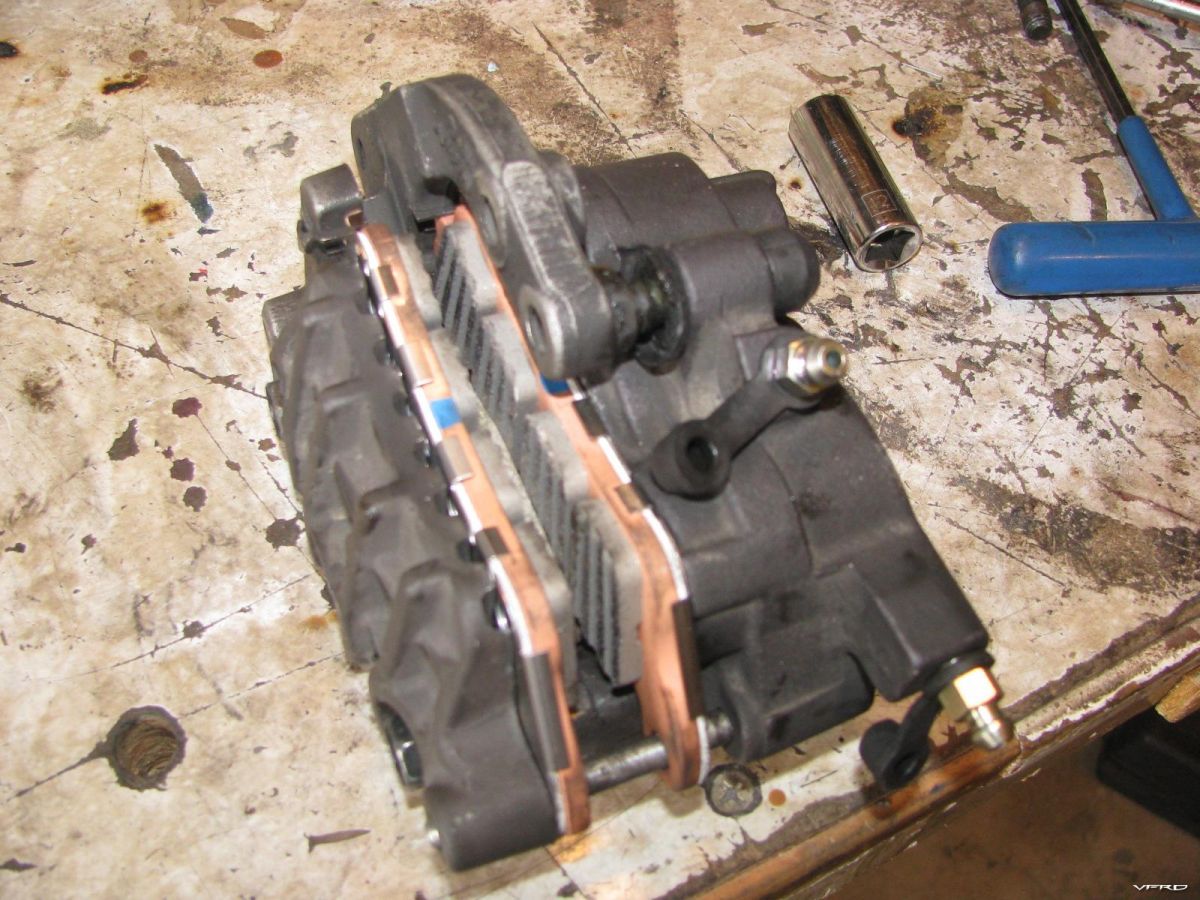

I keep delving into this bike deeper and deeper and finding all sorts of problems, I know my rear brake has been dragging so I decided to get some new parts and rebuild it. It was a mess, the rubber seals were hard as rocks, and the bellows covering the slider pins were torn and the pins were covered in caked on brake dust not sliding at all.

rear brake rebuild replaced the seals, pads, bleeders, cleaned up and polished the pistons

One rebuilt rear brake caliper high temp grease on the sliders, new bolts, new pads, new bleeders, new seals.

I just about got that done and decided to check the swing arm and it was slightly loose when moving side to side and indication that the bearing are shot. So I took it off too, found about 4 inches of caked on oily dirt on the top and side of the swing arm it was just a mess. When I took the axle out I noticed it was in awful shape partially rusted and I think it was the issue since it looked worn where the spacers fit. I run my fingers across the needle bearings and if felt like it was full of grime, the other bearing on the other side seemed fit though. I ordered new bearings, new axle and new spacers cause I am not sure where that play was comming from, along with new dust seals. I have no idea how I am going to get the needle bearings out? Or press in new ones? I dont have the right tools for that.

Swing arm removed she had a little play in the pivot axle!

Some good news I got my wheels and hub back from the powder coater and they look great!

Powdercoated hub it was looking rather dull so I had it done too

Wheels just back from the powder coater Spectrum Powder Works here in Colorado Springs - loving how they look

I got bored with getting greasy so I cleaned up and took a nap, I dont have the parts in yet to start putting it back together and I still have to get that darned broken header stud out! I ordered new studs and a carbide drill bit since my bits dont seem to be able to get the job done, I really dont want to take the head off and take it to a machine shop to get that stud out - hopefully that drill bit will do the job! I had to keep my parts orgainized so I put the little washers, seals, bolts, nuts, connectors and what nots into little baggies seperated by what they came off of. I did manage to get the stator back in and put the new stator cover on with a gasket - should not leak I treated it with a thin coat of yamabond 5 and let it dry like it says to do on the tube. Lots of work left to do its takeing nearly all my free time off work, but I enjoy it!

filling in sratches and holes with poly flex slowly getting the PITA job done of repairing plastics

RECAP OF WORK DONE AND WORK LEFT TO DO

- fork rebuild - new seals new oil done

- inspect head bearings - done

- bought new wheels - stripped and powdercoated - installed new bearings and dust seals done

- replaced stator cover - reinstalled inspected and tested stator new gaskets repaired oil leak done

- removed old accessory wires - rework heated seat with a new heat troller, reroute wires in a common conduit.

- find a better spot for the pc-usb

- rework the autovox unit

- installed two powerlets center post for the garmin zumo, and rear kit for my heated vest - wired up a side plug adaptor

Yet to do

- repair broken header studs install new header gaskets

- replace bearings in the ecentric and swing arm pivot axles degrease that unit

- replace the crappy plastic chain gaurd and hugger

- reupolster my seat with new leather or leather like matierial

- replace worn foam in the seat

- finish repairs to the plastics

- complete paint stripping on the tank

- sand and prime the plastics and paint

- replace the fuel filter since I have the pump removed

- PAINT THE BIKE

- GET IT BACK TOGETHER CORRECTLY

4 Comments

Recommended Comments